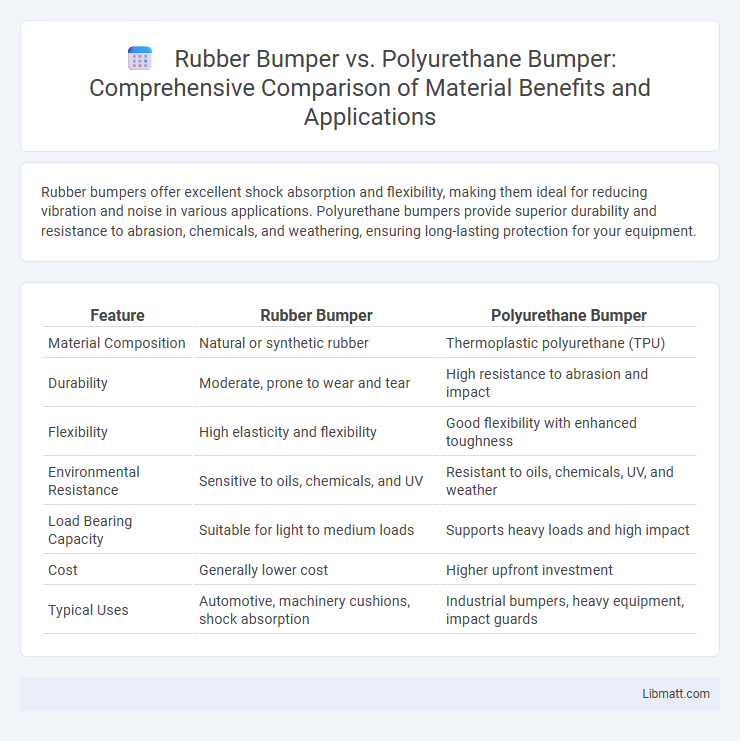

Rubber bumpers offer excellent shock absorption and flexibility, making them ideal for reducing vibration and noise in various applications. Polyurethane bumpers provide superior durability and resistance to abrasion, chemicals, and weathering, ensuring long-lasting protection for your equipment.

Table of Comparison

| Feature | Rubber Bumper | Polyurethane Bumper |

|---|---|---|

| Material Composition | Natural or synthetic rubber | Thermoplastic polyurethane (TPU) |

| Durability | Moderate, prone to wear and tear | High resistance to abrasion and impact |

| Flexibility | High elasticity and flexibility | Good flexibility with enhanced toughness |

| Environmental Resistance | Sensitive to oils, chemicals, and UV | Resistant to oils, chemicals, UV, and weather |

| Load Bearing Capacity | Suitable for light to medium loads | Supports heavy loads and high impact |

| Cost | Generally lower cost | Higher upfront investment |

| Typical Uses | Automotive, machinery cushions, shock absorption | Industrial bumpers, heavy equipment, impact guards |

Introduction to Rubber and Polyurethane Bumpers

Rubber bumpers provide excellent shock absorption and vibration dampening, making them suitable for applications requiring flexibility and resilience under impact. Polyurethane bumpers offer superior abrasion resistance and load-bearing capacity, ideal for environments with heavy wear and tear. Both materials deliver effective protection but differ in durability, elasticity, and chemical resistance tailored to specific industrial needs.

Material Composition: Rubber vs Polyurethane

Rubber bumpers are made from natural or synthetic rubber compounds that offer excellent flexibility, impact absorption, and resistance to abrasion and weathering. Polyurethane bumpers consist of a polymer material that combines the elasticity of rubber with enhanced toughness, superior load-bearing capacity, and resistance to chemicals and oils. Your choice between rubber and polyurethane bumpers should consider the specific environmental conditions and durability requirements of your application.

Performance and Durability Comparison

Rubber bumpers excel in shock absorption and flexibility, making them ideal for impact protection but may degrade faster under harsh environmental conditions. Polyurethane bumpers offer superior abrasion resistance and longevity, maintaining structural integrity in extreme temperatures and under heavy loads. The durability of polyurethane bumpers outperforms rubber, especially in industrial settings where prolonged wear and chemical exposure are common.

Impact Absorption Capabilities

Rubber bumpers provide excellent impact absorption due to their natural elasticity and ability to dissipate energy upon collision, making them ideal for applications requiring cushioning and vibration damping. Polyurethane bumpers offer superior impact resistance with higher tensile strength and durability, maintaining shape and performance even under repeated stress and harsh environmental conditions. The choice between rubber and polyurethane bumpers depends on the specific impact absorption requirements, where rubber excels in flexibility and shock absorption, while polyurethane is preferred for heavy-duty, long-lasting protection.

Resistance to Environmental Factors

Rubber bumpers exhibit strong resistance to water, UV rays, and ozone, making them suitable for outdoor applications exposed to harsh weather conditions. Polyurethane bumpers provide superior resistance to oils, chemicals, abrasion, and extreme temperatures, ensuring longer durability in industrial environments. Choosing the right bumper depends on your specific environmental exposure and performance requirements.

Cost and Value Considerations

Rubber bumpers generally offer a lower initial cost compared to polyurethane bumpers, making them a budget-friendly option for basic impact absorption needs. Polyurethane bumpers provide greater durability and resistance to wear, chemicals, and weather, resulting in longer service life and reduced replacement frequency, which enhances overall value over time. Your choice should balance upfront expenses with long-term performance benefits to maximize cost-effectiveness in your specific application.

Installation and Maintenance Differences

Rubber bumpers offer straightforward installation with flexibility for slight adjustments due to their pliable nature, often requiring simple adhesive or screw mounting. Polyurethane bumpers demand precise installation because of their rigidity and may involve more specialized tools or anchors to ensure a secure fit. Your maintenance routines will vary, with rubber bumpers needing periodic inspections for wear and tear while polyurethane bumpers typically resist deformation and chemicals, requiring less frequent upkeep.

Applications in Various Industries

Rubber bumpers excel in automotive, aerospace, and electronics industries due to their superior shock absorption and vibration dampening properties. Polyurethane bumpers are favored in heavy-duty industrial machinery and material handling sectors for their exceptional abrasion resistance and load-bearing capacity. Choosing the right bumper material enhances Your equipment's durability and operational efficiency across diverse industrial applications.

Pros and Cons of Rubber Bumpers

Rubber bumpers offer excellent shock absorption and noise reduction, making them ideal for protecting surfaces and equipment from impact damage. They are flexible, easy to install, and resistant to weather and chemicals, but can degrade faster under UV exposure and heavy abrasion compared to polyurethane bumpers. Rubber bumpers typically provide better cushioning but may lack the durability and load-bearing capacity of polyurethane alternatives in industrial applications.

Pros and Cons of Polyurethane Bumpers

Polyurethane bumpers offer excellent abrasion resistance, high elasticity, and superior load-bearing capacity, making them ideal for heavy-duty applications and environments with frequent impact. However, their higher cost compared to rubber bumpers and potential susceptibility to UV degradation can limit their use in outdoor settings without protective treatments. Their chemical resistance and durability provide a longer lifespan, but installation may require expert handling due to their rigidity.

Rubber Bumper vs Polyurethane Bumper Infographic

libmatt.com

libmatt.com