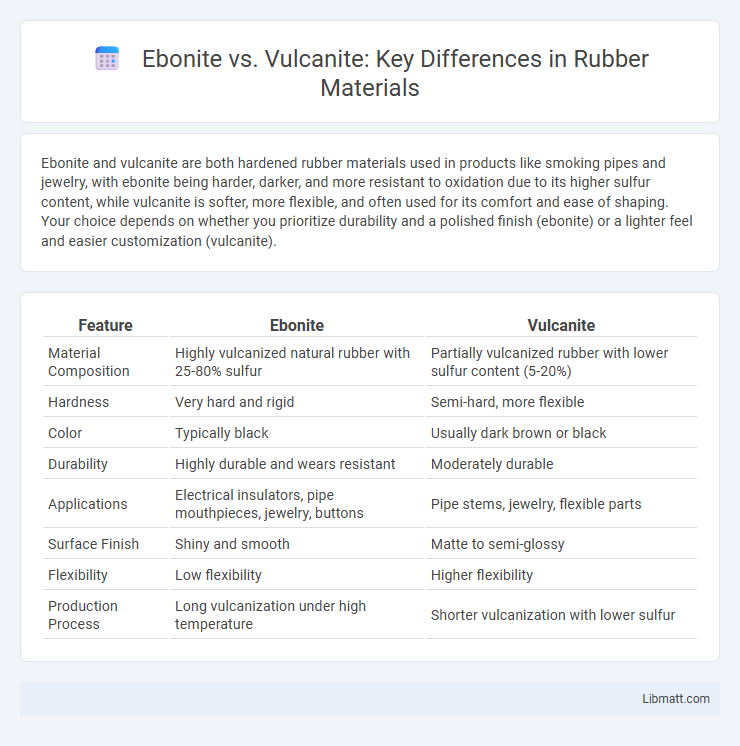

Ebonite and vulcanite are both hardened rubber materials used in products like smoking pipes and jewelry, with ebonite being harder, darker, and more resistant to oxidation due to its higher sulfur content, while vulcanite is softer, more flexible, and often used for its comfort and ease of shaping. Your choice depends on whether you prioritize durability and a polished finish (ebonite) or a lighter feel and easier customization (vulcanite).

Table of Comparison

| Feature | Ebonite | Vulcanite |

|---|---|---|

| Material Composition | Highly vulcanized natural rubber with 25-80% sulfur | Partially vulcanized rubber with lower sulfur content (5-20%) |

| Hardness | Very hard and rigid | Semi-hard, more flexible |

| Color | Typically black | Usually dark brown or black |

| Durability | Highly durable and wears resistant | Moderately durable |

| Applications | Electrical insulators, pipe mouthpieces, jewelry, buttons | Pipe stems, jewelry, flexible parts |

| Surface Finish | Shiny and smooth | Matte to semi-glossy |

| Flexibility | Low flexibility | Higher flexibility |

| Production Process | Long vulcanization under high temperature | Shorter vulcanization with lower sulfur |

Introduction to Ebonite and Vulcanite

Ebonite and Vulcanite are both hard rubber materials primarily used in manufacturing and crafting, particularly for pipe stems and billiard balls. Ebonite is created by vulcanizing natural rubber with a higher sulfur content, resulting in a dense, durable material with excellent resistance to heat and chemicals. Vulcanite, also known as hard rubber, contains less sulfur, making it slightly softer and more flexible, commonly valued for its ease of machining and polishing in specialized applications.

Historical Background and Development

Ebonite, developed in the mid-19th century by Charles Goodyear, was one of the first hard rubber materials used extensively in industrial applications and everyday items like pipe stems and fountain pens. Vulcanite, a specific type of ebonite, was created through the vulcanization of natural rubber with sulfur, enhancing its durability and elasticity, making it a popular choice in the early 20th century for musical instruments, jewelry, and other precision products. Understanding these materials' historical development highlights their impact on manufacturing processes and allows you to appreciate their enduring influence in modern design and craftsmanship.

Chemical Composition and Material Properties

Ebonite, also known as hard rubber, is composed of vulcanized natural rubber with a high sulfur content, typically around 25-35%, resulting in a rigid, durable material with excellent electrical insulation properties. Vulcanite contains less sulfur, usually between 10-20%, making it more flexible and softer, which affects its wear resistance and mechanical strength. Both materials exhibit resistance to chemical corrosion, but ebonite stands out for its superior hardness and thermal stability in industrial applications.

Manufacturing Processes Compared

Ebonite is produced by vulcanizing natural rubber with a high sulfur content at elevated temperatures, resulting in a hard, durable material commonly used in bowling balls and pipe stems. Vulcanite, often confused with Ebonite, undergoes a similar but less intense vulcanization process with lower sulfur levels, yielding a softer, more workable product primarily used in jewelry and dental appliances. Understanding the manufacturing differences helps you choose between the rigid strength of Ebonite and the flexible qualities of Vulcanite for your specific application needs.

Physical Characteristics: Appearance and Texture

Ebonite is a hard, dense material with a smooth, glossy finish, often appearing in deep, uniform black or rich, dark hues. Vulcanite has a slightly softer texture, characterized by a matte or semi-gloss surface with subtle grain patterns and often features a dark brown or black color. Your choice between Ebonite and Vulcanite hinges on whether you prefer Ebonite's polished shine or Vulcanite's more tactile, organic feel.

Durability and Longevity

Ebonite offers superior durability due to its hard, vulcanized rubber composition, resisting wear and maintaining shape over time. Vulcanite, while softer and more flexible, tends to wear down faster but provides a comfortable grip, making it ideal for short-term use. You should choose Ebonite for longevity if durability is your priority, while Vulcanite suits applications needing immediate comfort.

Common Uses and Applications

Ebonite and vulcanite are both hard rubber materials widely used in the manufacture of electrical insulators, smoking pipes, and musical instrument mouthpieces due to their durability and heat resistance. Ebonite, with its higher sulfur content, is commonly preferred for high-wear applications like bowling balls and fountain pen bodies, offering excellent rigidity and polished surfaces. Vulcanite, being slightly softer and more flexible, is often favored in dental plates and jewelry for its ease of shaping and comfortable wear.

Advantages and Disadvantages

Ebonite, also known as hard rubber, offers durability and a smooth finish that resists chipping, making it ideal for long-lasting products like pipe stems and pen grips. Vulcanite, a softer material derived from natural rubber, provides greater comfort due to its flexibility but requires more maintenance as it can oxidize and discolor over time. Choosing between Ebonite and Vulcanite depends on your preference for durability versus comfort and the level of upkeep you're willing to invest.

Maintenance and Care Differences

Ebonite requires periodic polishing to maintain its shine and prevent oxidation, while Vulcanite needs more frequent cleaning to avoid discoloration and tartar buildup. You should use a soft cloth and mild soap for Vulcanite, avoiding harsh chemicals that can damage its surface, whereas Ebonite benefits from specialized pipe cleaners or care products. Both materials demand regular inspection for cracks or wear, but Vulcanite's sensitivity to moisture calls for extra attention in drying to preserve its durability.

Choosing Between Ebonite and Vulcanite

When choosing between ebonite and vulcanite, consider that ebonite is a hard, durable material made from vulcanized rubber with high sulfur content, providing excellent resistance to wear and heat. Vulcanite, also known as hard rubber, contains less sulfur and offers a slightly softer texture and greater flexibility, making it ideal for comfortable grips and mouthpieces. Understanding the specific application requirements for durability, comfort, and appearance will guide the best choice between these two closely related materials.

Ebonite vs Vulcanite Infographic

libmatt.com

libmatt.com