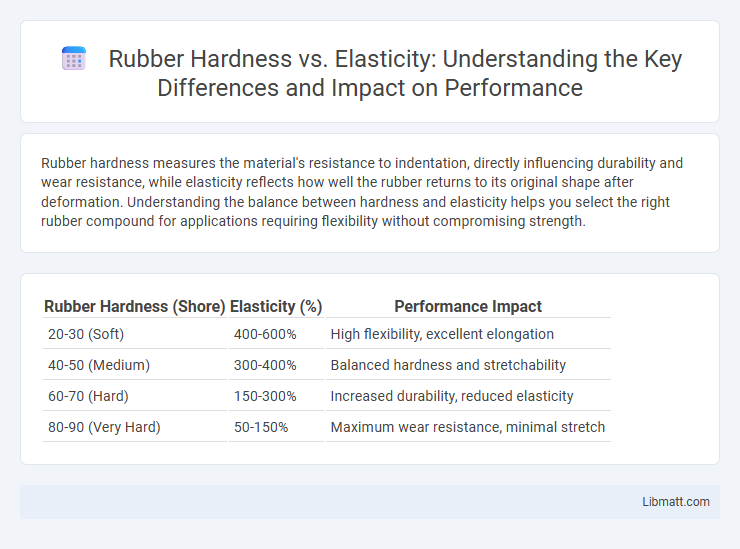

Rubber hardness measures the material's resistance to indentation, directly influencing durability and wear resistance, while elasticity reflects how well the rubber returns to its original shape after deformation. Understanding the balance between hardness and elasticity helps you select the right rubber compound for applications requiring flexibility without compromising strength.

Table of Comparison

| Rubber Hardness (Shore) | Elasticity (%) | Performance Impact |

|---|---|---|

| 20-30 (Soft) | 400-600% | High flexibility, excellent elongation |

| 40-50 (Medium) | 300-400% | Balanced hardness and stretchability |

| 60-70 (Hard) | 150-300% | Increased durability, reduced elasticity |

| 80-90 (Very Hard) | 50-150% | Maximum wear resistance, minimal stretch |

Understanding Rubber Hardness and Elasticity

Rubber hardness is measured by the Shore durometer scale, indicating the material's resistance to indentation and directly affecting its durability and wear resistance. Elasticity refers to the rubber's ability to return to its original shape after deformation, crucial for applications requiring flexibility and impact absorption. Understanding the relationship between hardness and elasticity helps optimize rubber formulations for specific industrial uses, balancing stiffness with flexibility.

Key Differences Between Hardness and Elasticity in Rubber

Rubber hardness measures the material's resistance to permanent indentation, often assessed by durometer scales like Shore A, while elasticity describes rubber's ability to return to its original shape after deformation, quantified by properties such as elongation at break and resilience. Hard rubber typically exhibits lower elasticity, making it less flexible but more durable under compressive forces, whereas softer rubber offers higher elasticity, enabling better stretch and recovery. Understanding these key differences between hardness and elasticity helps you select the optimal rubber type for applications requiring either structural integrity or flexibility.

Measuring Rubber Hardness: Tools and Methods

Measuring rubber hardness involves using tools like the Shore durometer, which gauges resistance to indentation on scales such as Shore A and Shore D, tailored for soft and hard rubbers respectively. Methods also include the use of IRHD (International Rubber Hardness Degrees) for precision in thin rubber samples and microhardness testers for specialized applications. Accurate measurement of rubber hardness ensures optimal elasticity characterization critical for product performance in industries like automotive and footwear manufacturing.

Assessing Elasticity: Tests and Indicators

Assessing rubber elasticity involves measuring its ability to return to original shape after deformation, commonly evaluated through tensile and elongation tests. Durometer hardness scales provide crucial indicators of stiffness, indirectly reflecting elasticity levels by quantifying surface resistance. Your choice of testing method directly impacts the accuracy of elasticity assessment, ensuring the rubber meets specific application requirements.

How Hardness Affects Rubber Performance

Rubber hardness significantly impacts its elasticity, influencing performance characteristics such as flexibility, resistance to deformation, and durability. Softer rubber with lower hardness values typically offers greater elasticity, enabling better shock absorption and flexibility, while harder rubber provides enhanced wear resistance and structural integrity under load. Selecting the appropriate hardness rating is crucial for optimizing rubber components in applications ranging from seals and gaskets to tires and vibration dampers.

The Role of Elasticity in Rubber Applications

Elasticity in rubber significantly influences its performance in diverse applications by enabling the material to stretch and return to its original shape without permanent deformation. Rubber hardness, measured by the Shore durometer scale, correlates with elasticity but does not fully define the material's ability to absorb energy and resist tearing. Your choice of rubber must balance hardness and elasticity to ensure durability, flexibility, and suitability for specific uses such as seals, gaskets, or vibration dampening components.

Factors Influencing Rubber Hardness and Elasticity

Rubber hardness and elasticity are significantly influenced by factors such as polymer composition, crosslink density, and filler type. Higher crosslink density increases hardness but reduces elasticity, while softer polymers with fewer crosslinks exhibit greater flexibility and stretchability. Your selection of rubber materials must balance these factors to achieve the desired performance for specific applications.

Choosing the Right Balance for Industrial Needs

Rubber hardness determines resistance to indentation, while elasticity measures the material's ability to return to its original shape after deformation. Selecting the right balance between hardness and elasticity is crucial for industrial applications, ensuring durability without compromising flexibility under stress. Your choice impacts performance factors such as wear resistance, sealing efficiency, and vibration dampening in machinery components.

Common Misconceptions: Hardness vs Elasticity

Rubber hardness refers to the material's resistance to indentation, typically measured by the Shore durometer scale, while elasticity describes rubber's ability to stretch and return to its original shape. A common misconception is that harder rubber is less elastic, but many hard rubbers can exhibit significant elasticity depending on their polymer structure. Understanding the distinct properties allows you to select the appropriate rubber type for applications requiring specific performance characteristics.

Future Trends in Rubber Material Engineering

Future trends in rubber material engineering emphasize the development of smart polymers that dynamically adjust hardness and elasticity in response to environmental stimuli. Advances in nanotechnology enable the incorporation of nanoparticles to enhance mechanical properties while maintaining flexibility. Research is increasingly focused on sustainable rubber composites combining bio-based materials with superior durability and tunable hardness-elasticity balance.

Rubber Hardness vs Elasticity Infographic

libmatt.com

libmatt.com