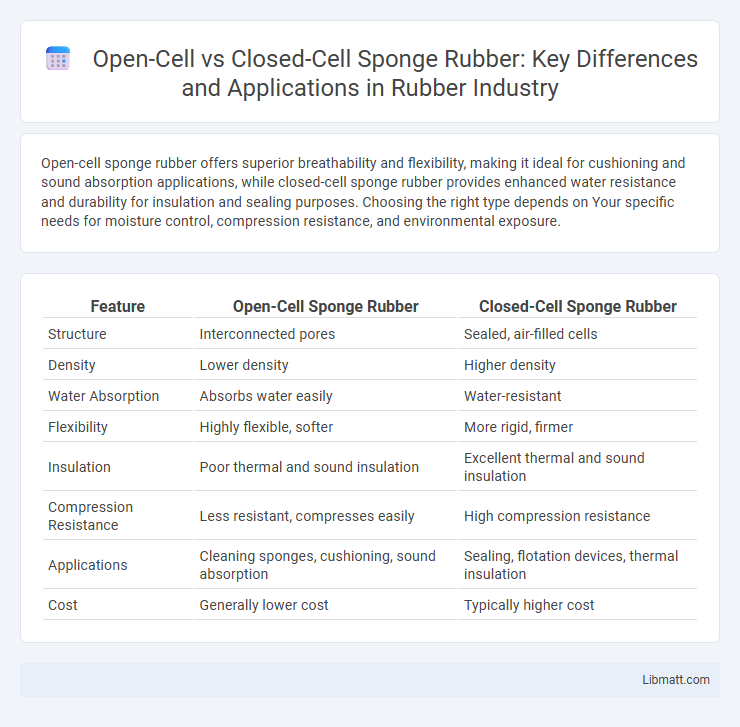

Open-cell sponge rubber offers superior breathability and flexibility, making it ideal for cushioning and sound absorption applications, while closed-cell sponge rubber provides enhanced water resistance and durability for insulation and sealing purposes. Choosing the right type depends on Your specific needs for moisture control, compression resistance, and environmental exposure.

Table of Comparison

| Feature | Open-Cell Sponge Rubber | Closed-Cell Sponge Rubber |

|---|---|---|

| Structure | Interconnected pores | Sealed, air-filled cells |

| Density | Lower density | Higher density |

| Water Absorption | Absorbs water easily | Water-resistant |

| Flexibility | Highly flexible, softer | More rigid, firmer |

| Insulation | Poor thermal and sound insulation | Excellent thermal and sound insulation |

| Compression Resistance | Less resistant, compresses easily | High compression resistance |

| Applications | Cleaning sponges, cushioning, sound absorption | Sealing, flotation devices, thermal insulation |

| Cost | Generally lower cost | Typically higher cost |

Introduction to Sponge Rubber

Sponge rubber is a versatile elastomeric material characterized by its cellular structure, which can be either open-cell or closed-cell. Open-cell sponge rubber has interconnected pores, making it softer, more flexible, and breathable, ideal for cushioning and sound absorption applications. Closed-cell sponge rubber features sealed cells filled with gas, providing superior insulation, water resistance, and durability for sealing and gasketing purposes.

What is Open-Cell Sponge Rubber?

Open-cell sponge rubber consists of interconnected pores that allow air and moisture to pass through, making it highly breathable and flexible. This structure provides excellent cushioning, sound absorption, and insulation properties while remaining lightweight. Common applications include sealing, padding, and filtration where ventilation and compressibility are essential.

What is Closed-Cell Sponge Rubber?

Closed-cell sponge rubber consists of tightly packed, individual cells filled with gas, making it highly resistant to water, air, and moisture penetration. This dense structure provides excellent insulation, buoyancy, and durability, making it ideal for sealing, gasketing, and vibration dampening applications. Your choice of closed-cell sponge rubber ensures superior performance in harsh environments where preventing fluid ingress and maintaining structural integrity are critical.

Key Differences Between Open-Cell and Closed-Cell

Open-cell sponge rubber features interconnected pores that allow air and moisture to pass through, providing excellent breathability and flexibility, making it ideal for cushioning and sound absorption. Closed-cell sponge rubber consists of tightly packed, sealed cells that are impermeable to air and water, offering superior insulation, buoyancy, and resistance to moisture and chemicals. Choosing between open-cell and closed-cell sponge rubber depends on your need for either cushioning and air flow or durability and waterproofing in your application.

Physical Properties Comparison

Open-cell sponge rubber features a softer texture and higher porosity, allowing air and moisture to pass through easily, which makes it ideal for cushioning and sound absorption. Closed-cell sponge rubber has a denser, more rigid structure with smaller, sealed cells that provide excellent water resistance, durability, and insulation against heat and cold. Your choice between these materials depends on whether you prioritize breathability and flexibility or strength and moisture resistance.

Applications of Open-Cell Sponge Rubber

Open-cell sponge rubber is highly effective in applications requiring sound absorption, such as acoustic insulation in studios, HVAC systems, and automotive interiors. Its porous structure allows air and moisture to pass through, making it suitable for cushioning, sealing, and impact protection in packaging and furniture. You can also find open-cell sponge rubber used in filtration systems and medical devices due to its breathability and flexibility.

Applications of Closed-Cell Sponge Rubber

Closed-cell sponge rubber is widely used in applications requiring high resistance to moisture, chemicals, and compression, such as sealing gaskets, insulation panels, and protective padding. Its dense structure prevents water absorption, making it ideal for automotive weatherstripping, marine seals, and HVAC systems. The material's durability and shock absorption capabilities also suit it for use in industrial machinery and electronic device cushioning.

Advantages and Disadvantages

Open-cell sponge rubber offers superior breathability and flexibility, making it ideal for cushioning and sound absorption but tends to absorb water and deteriorate faster. Closed-cell sponge rubber provides excellent water resistance, insulation, and durability, making it suitable for sealing and flotation applications, yet is generally stiffer and less compressible. Your choice depends on whether you prioritize moisture resistance or comfort and airflow in your specific use case.

How to Choose the Right Sponge Rubber

Choosing the right sponge rubber depends on application requirements such as flexibility, insulation, and water resistance. Open-cell sponge rubber offers excellent breathability and cushioning, ideal for soundproofing and padding where moisture absorption is acceptable. Closed-cell sponge rubber provides superior water resistance, durability, and airtight sealing, making it suitable for weatherproofing, gasketing, and flotation devices.

Conclusion: Selecting the Best Sponge Rubber for Your Needs

Open-cell sponge rubber offers superior breathability and flexibility, making it ideal for applications requiring cushioning and sound absorption, while closed-cell sponge rubber provides excellent moisture resistance, durability, and insulation properties, suited for sealing and flotation uses. Evaluating factors such as environmental exposure, required flexibility, and moisture resistance ensures the selection aligns with performance requirements. Choosing the appropriate sponge rubber type enhances product longevity and efficiency in specific industrial, automotive, or household applications.

Open-cell vs Closed-cell sponge rubber Infographic

libmatt.com

libmatt.com