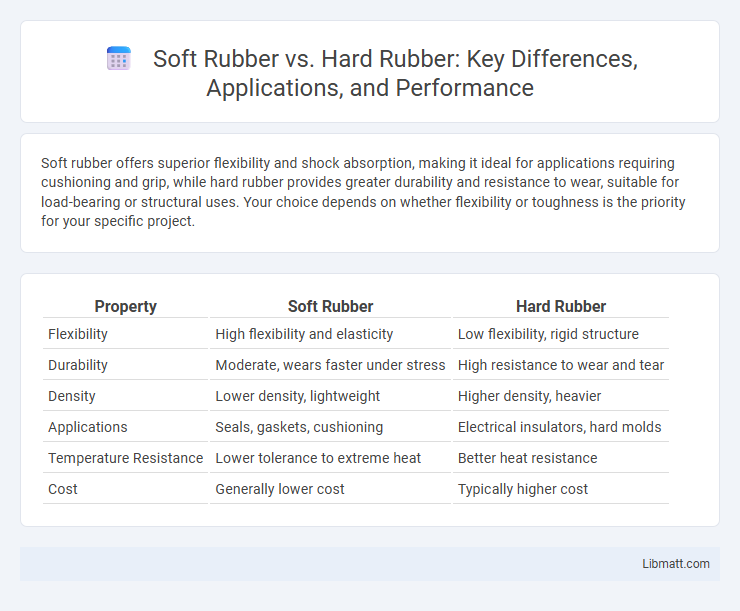

Soft rubber offers superior flexibility and shock absorption, making it ideal for applications requiring cushioning and grip, while hard rubber provides greater durability and resistance to wear, suitable for load-bearing or structural uses. Your choice depends on whether flexibility or toughness is the priority for your specific project.

Table of Comparison

| Property | Soft Rubber | Hard Rubber |

|---|---|---|

| Flexibility | High flexibility and elasticity | Low flexibility, rigid structure |

| Durability | Moderate, wears faster under stress | High resistance to wear and tear |

| Density | Lower density, lightweight | Higher density, heavier |

| Applications | Seals, gaskets, cushioning | Electrical insulators, hard molds |

| Temperature Resistance | Lower tolerance to extreme heat | Better heat resistance |

| Cost | Generally lower cost | Typically higher cost |

Introduction to Soft Rubber and Hard Rubber

Soft rubber offers excellent flexibility, resilience, and cushioning, making it ideal for applications requiring impact absorption and adaptability to various shapes. Hard rubber, also known as ebonite, is characterized by its rigidity, high durability, and resistance to heat and chemicals, commonly used in electrical insulation and heavy-duty industrial components. Understanding the key properties and specific use cases of soft and hard rubber enables informed material selection for diverse manufacturing and engineering needs.

Key Differences Between Soft and Hard Rubber

Soft rubber offers greater flexibility and elasticity, making it ideal for applications requiring cushioning or vibration absorption, while hard rubber provides superior durability and resistance to abrasion, suitable for structural or load-bearing uses. The key differences lie in their physical properties; soft rubber tends to have a lower durometer rating, ensuring gentler compression and better grip, whereas hard rubber possesses a higher durometer, resulting in rigidity and enhanced wear resistance. Your choice between soft and hard rubber should consider the specific performance requirements such as flexibility, strength, and environmental exposure.

Material Composition and Properties

Soft rubber typically consists of natural rubber or styrene-butadiene rubber with added plasticizers, resulting in a flexible, elastic material with high tensile strength and excellent abrasion resistance. Hard rubber, also known as ebonite, is made by vulcanizing natural rubber with a large amount of sulfur, producing a rigid, durable material with high hardness, chemical resistance, and low electrical conductivity. The distinct differences in polymer cross-linking density between soft and hard rubber determine their mechanical properties and suitability for various industrial applications.

Common Applications of Soft Rubber

Soft rubber is widely used in applications requiring flexibility and cushioning, such as seals, gaskets, and vibration dampeners in automotive and industrial machinery. Its elasticity makes it ideal for medical devices, footwear soles, and shock-absorbing components. You can rely on soft rubber for products demanding comfort, durability, and resistance to wear under repeated stress.

Common Applications of Hard Rubber

Hard rubber, also known as ebonite, is commonly used in electrical insulators, due to its excellent insulating properties and durability under high voltage conditions. It's prevalent in producing tool handles, bowling balls, and fountain pen barrels where a rigid, wear-resistant material is essential. Your choice of hard rubber ensures enhanced longevity and performance in applications requiring strength and electrical insulation.

Durability and Performance Comparison

Soft rubber offers superior flexibility and impact absorption, making it ideal for applications requiring cushioning and grip, but it may wear out faster under heavy stress. Hard rubber provides greater durability and resistance to abrasion, suitable for high-impact and heavy-use environments, ensuring longer service life. Performance varies with usage context, as soft rubber excels in shock absorption while hard rubber maintains structural integrity under continuous friction.

Flexibility and Elasticity Factors

Soft rubber exhibits greater flexibility and elasticity due to its lower cross-link density, allowing it to stretch and recover more easily under stress. Hard rubber possesses a higher degree of vulcanization, which increases rigidity and reduces its ability to deform elastically. These differences directly impact applications where shock absorption, resilience, and adaptability to variable forces are critical.

Cost Considerations: Soft vs Hard Rubber

Soft rubber generally incurs higher manufacturing costs due to its flexible properties and longer curing times, while hard rubber is more cost-effective because of simpler production processes and faster setting. Your choice between soft and hard rubber affects budget planning, as soft rubber's durability might reduce replacement frequency despite its higher upfront price. Cost considerations should factor in both initial investment and long-term maintenance expenses to ensure optimal value.

Environmental Impact and Sustainability

Soft rubber typically has a lower environmental impact due to its higher biodegradability and easier recycling potential compared to hard rubber, which often contains more synthetic additives and curing agents that hinder decomposition. Production of soft rubber generally consumes less energy and produces fewer greenhouse gases, making it a more sustainable option for eco-conscious applications. However, innovations in hard rubber recycling and the development of bio-based hard rubbers are improving sustainability profiles in industrial use cases.

Choosing the Right Rubber for Your Needs

Selecting the right rubber depends on the application requirements: soft rubber offers superior flexibility, impact absorption, and cushioning, making it ideal for seals, gaskets, and vibration dampening. Hard rubber provides greater durability, resistance to abrasion, and structural support, suited for industrial parts and heavy-duty components. Evaluating factors like load, flexibility, and environmental exposure ensures optimal performance between soft and hard rubber materials.

Soft Rubber vs Hard Rubber Infographic

libmatt.com

libmatt.com