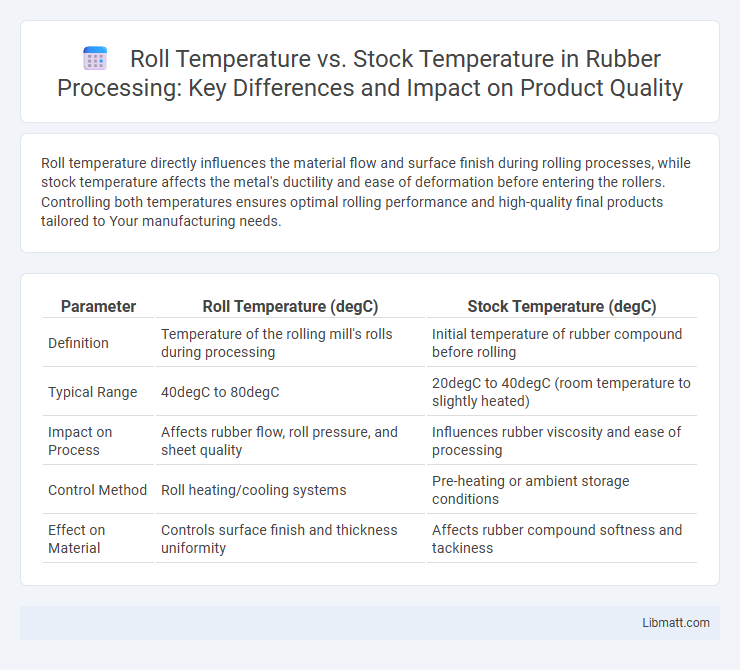

Roll temperature directly influences the material flow and surface finish during rolling processes, while stock temperature affects the metal's ductility and ease of deformation before entering the rollers. Controlling both temperatures ensures optimal rolling performance and high-quality final products tailored to Your manufacturing needs.

Table of Comparison

| Parameter | Roll Temperature (degC) | Stock Temperature (degC) |

|---|---|---|

| Definition | Temperature of the rolling mill's rolls during processing | Initial temperature of rubber compound before rolling |

| Typical Range | 40degC to 80degC | 20degC to 40degC (room temperature to slightly heated) |

| Impact on Process | Affects rubber flow, roll pressure, and sheet quality | Influences rubber viscosity and ease of processing |

| Control Method | Roll heating/cooling systems | Pre-heating or ambient storage conditions |

| Effect on Material | Controls surface finish and thickness uniformity | Affects rubber compound softness and tackiness |

Introduction to Roll Temperature and Stock Temperature

Roll temperature refers to the heat level of the rolls used in manufacturing or metalworking processes, which directly impacts material deformation and surface finish quality. Stock temperature denotes the initial temperature of the raw material before it undergoes rolling or forming, influencing its malleability and final mechanical properties. Understanding the relationship between roll temperature and stock temperature is crucial for optimizing Your production process and ensuring consistent product performance.

Understanding the Basics of Roll and Stock Temperatures

Roll temperature directly influences the friction and heat transfer during rolling processes, impacting material deformation and surface finish. Stock temperature affects the material's ductility and flow stress, determining how easily it can be shaped without defects. Understanding the interaction between roll temperature and stock temperature is essential for optimizing your manufacturing process and ensuring consistent product quality.

Key Differences Between Roll Temperature and Stock Temperature

Roll temperature refers to the heat level of the rolls used in industrial processes such as metalworking, directly influencing material deformation and surface quality. Stock temperature denotes the temperature of the raw material before processing, affecting its ductility, flow stress, and final mechanical properties. Key differences include roll temperature primarily impacting tooling performance and surface finish, while stock temperature governs material behavior and process efficiency.

Importance of Temperature Control in Manufacturing

Precise control of roll temperature and stock temperature is critical in manufacturing processes such as rolling and extrusion to ensure product quality and dimensional accuracy. Maintaining optimal roll temperature prevents surface defects and material sticking, while consistent stock temperature ensures uniform deformation and mechanical properties. Effective temperature management reduces energy consumption, minimizes equipment wear, and enhances overall process stability.

Factors Influencing Roll Temperature

Roll temperature is primarily influenced by factors such as friction between the roll and the stock, roll speed, and the material properties of both the roll and the stock being processed. Heat generation occurs due to mechanical work and friction, causing the roll temperature to rise above the stock temperature, which is influenced by the initial temperature and thermal conductivity of the material. Cooling methods, roll surface conditions, and contact pressure further affect the roll temperature during the rolling process.

Factors Affecting Stock Temperature

Stock temperature during rolling is influenced by initial material temperature, deformation rate, and friction between the roll and stock surface. Higher rolling speeds increase heat generation, elevating the stock temperature, while cooling conditions and roll lubrication also significantly affect thermal exchange. Metallurgical properties such as thermal conductivity and specific heat capacity of the stock material determine how quickly temperature rises under mechanical work.

Impact of Roll and Stock Temperatures on Product Quality

Roll temperature and stock temperature critically influence metal forming product quality by affecting material properties such as ductility and surface finish. Higher roll temperatures typically enhance metal plasticity, reducing internal stresses and surface defects, while optimal stock temperature ensures uniform deformation and minimizes cracking. Precise control of both temperatures improves dimensional accuracy, mechanical strength, and overall consistency in rolled products.

Best Practices for Measuring and Monitoring Temperatures

Accurate measurement of roll temperature and stock temperature is critical for optimizing paper production quality and machine reliability. Best practices include using infrared sensors or thermocouples placed strategically on the roll surface and within the stock flow to capture real-time temperature variations. Regular calibration of temperature sensors, continuous data logging, and integration with process control systems enable early detection of anomalies and ensure consistent thermal conditions throughout the production line.

Common Issues Related to Improper Temperature Management

Improper management of roll temperature and stock temperature often leads to issues like sheet tearing, inconsistent thickness, and surface defects in manufacturing processes. Variations in roll temperature can cause uneven material hardness, while incorrect stock temperature affects material flexibility, resulting in poor final product quality. Ensuring precise control over both temperatures is essential to maintain optimal material performance and minimize production downtime.

Conclusion: Optimizing Roll and Stock Temperatures for Efficiency

Optimizing roll temperature and stock temperature directly impacts the efficiency and quality of industrial processes such as metal rolling or extrusion. Maintaining the right roll temperature ensures proper material deformation and surface finish, while controlling stock temperature improves flow characteristics and reduces energy consumption. Your process efficiency can significantly improve by balancing these temperatures to minimize defects and maximize throughput.

Roll Temperature vs Stock Temperature Infographic

libmatt.com

libmatt.com