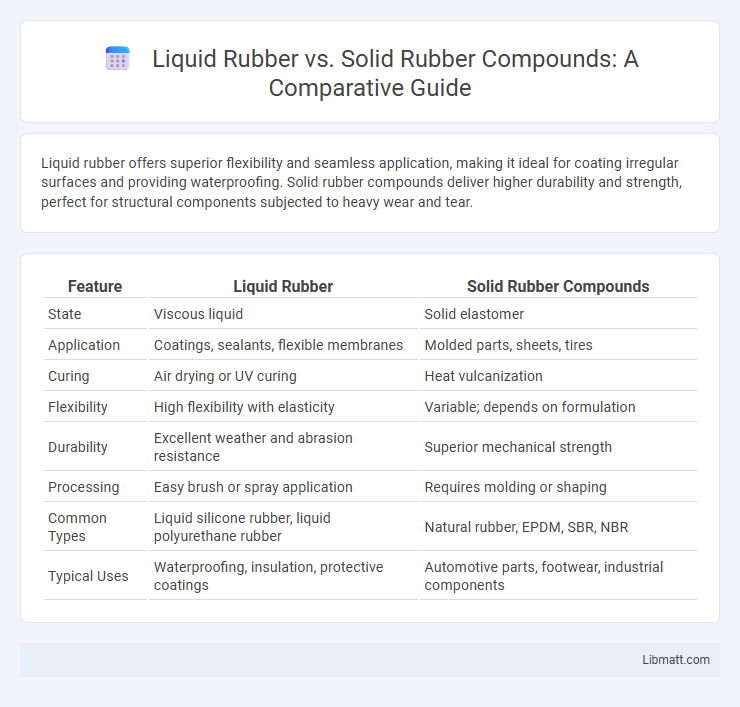

Liquid rubber offers superior flexibility and seamless application, making it ideal for coating irregular surfaces and providing waterproofing. Solid rubber compounds deliver higher durability and strength, perfect for structural components subjected to heavy wear and tear.

Table of Comparison

| Feature | Liquid Rubber | Solid Rubber Compounds |

|---|---|---|

| State | Viscous liquid | Solid elastomer |

| Application | Coatings, sealants, flexible membranes | Molded parts, sheets, tires |

| Curing | Air drying or UV curing | Heat vulcanization |

| Flexibility | High flexibility with elasticity | Variable; depends on formulation |

| Durability | Excellent weather and abrasion resistance | Superior mechanical strength |

| Processing | Easy brush or spray application | Requires molding or shaping |

| Common Types | Liquid silicone rubber, liquid polyurethane rubber | Natural rubber, EPDM, SBR, NBR |

| Typical Uses | Waterproofing, insulation, protective coatings | Automotive parts, footwear, industrial components |

Introduction to Liquid vs Solid Rubber Compounds

Liquid rubber compounds offer enhanced flexibility and ease of application compared to solid rubber, allowing seamless coating, sealing, and molding in complex shapes. Solid rubber compounds provide superior durability and structural integrity, making them ideal for heavy-duty industrial uses and high-stress environments. Understanding the molecular structure and curing processes distinguishes liquid elastomers, which cure through chemical cross-linking, from solid rubber, typically formed by vulcanization techniques.

Composition and Manufacturing Differences

Liquid rubber consists mainly of polymer chains suspended in a solvent or water, allowing for easy application through spraying or dipping processes, while solid rubber compounds are composed of vulcanized elastomers mixed with fillers and curing agents, providing a dense, elastic material. Manufacturing liquid rubber involves blending polymers into a liquid form followed by curing through heat or chemical reactions, whereas solid rubber compounds require mixing raw rubber with additives, shaping, and vulcanization under pressure and heat to achieve the final product. These compositional and manufacturing differences impact flexibility, application methods, and performance characteristics in industrial and commercial uses.

Key Physical Properties Comparison

Liquid rubber exhibits superior flexibility and excellent elongation properties compared to solid rubber compounds, making it ideal for applications requiring extensive stretch and recovery. Solid rubber compounds offer higher tensile strength and greater abrasion resistance, suitable for heavy-duty uses demanding durability and impact resistance. Your choice between these materials depends on the balance needed between elasticity and toughness for specific industrial or commercial applications.

Application Areas: Liquid Rubber

Liquid rubber compounds excel in waterproofing applications, including roofing, pond lining, and pipe coating due to their seamless, flexible, and durable characteristics. Their ability to form airtight and watertight seals makes them ideal for automotive undercoats, corrosion protection, and protective coatings in industrial settings. You can rely on liquid rubber for versatile applications that require easy application and strong adhesion to irregular surfaces.

Application Areas: Solid Rubber

Solid rubber compounds find extensive use in automotive components, industrial seals, and heavy-duty conveyor belts due to their durability and resistance to wear. These materials excel in applications requiring high mechanical strength, such as tire manufacturing and vibration dampening products. Their ability to withstand extreme temperatures and harsh chemical environments makes them ideal for aerospace and construction sectors.

Performance Under Stress and Flexibility

Liquid rubber exhibits superior flexibility and resilience under repetitive stress due to its elastomeric molecular structure, allowing it to stretch and recover without cracking. Solid rubber compounds offer higher tensile strength and abrasion resistance, making them ideal for applications requiring durability under heavy mechanical load. The choice between liquid and solid rubber depends on the balance needed between flexibility in dynamic conditions and robustness in static, high-stress environments.

Durability and Longevity

Liquid rubber compounds offer superior durability due to their flexible, seamless application that withstands cracking and environmental wear better than solid rubber. Solid rubber compounds provide robust structural integrity but are more prone to degradation from repeated flexing and abrasive forces over time. The chemical composition of liquid rubber enhances resistance to UV radiation, ozone, and chemical exposure, contributing to a longer lifespan in harsh conditions compared to traditional solid rubber materials.

Environmental Resistance: Chemical, UV, and Weather

Liquid rubber displays superior environmental resistance due to its seamless, flexible coating that effectively blocks chemical infiltration, UV radiation, and weather elements, preventing cracks and degradation common in solid rubber compounds. Solid rubber compounds tend to absorb chemicals and degrade under prolonged UV exposure, leading to hardening, brittleness, and reduced lifespan. The molecular cross-linking in liquid rubber enhances durability against weather extremes, making it preferable for applications requiring long-term resistance to harsh environmental conditions.

Installation and Handling Techniques

Liquid rubber offers easier application and seamless coverage through spraying or brushing, ideal for complex shapes and irregular surfaces, while solid rubber requires precise cutting and fitting, often combined with adhesives or mechanical fastening. Handling liquid rubber demands careful mixing and controlled drying times to ensure uniform thickness and adhesion, whereas solid rubber installation emphasizes physical placement and compression to secure a firm bond. Both materials benefit from surface preparation, but liquid rubber installations typically allow faster turnaround and reduced labor compared to solid rubber compounds.

Cost Considerations and Suitability

Liquid rubber compounds typically offer lower initial production costs due to simpler application methods and reduced waste, making them ideal for quick repairs and coatings, while solid rubber compounds require higher upfront investment in molding and processing equipment but deliver superior durability and load-bearing performance. Cost considerations favor liquid rubber for small-scale or temporary applications, whereas solid rubber compounds are more suitable for heavy-duty industries demanding long-term resilience. The choice between liquid and solid rubber hinges on balancing budget constraints with specific performance requirements like elasticity, wear resistance, and environmental exposure.

Liquid rubber vs Solid rubber compounds Infographic

libmatt.com

libmatt.com