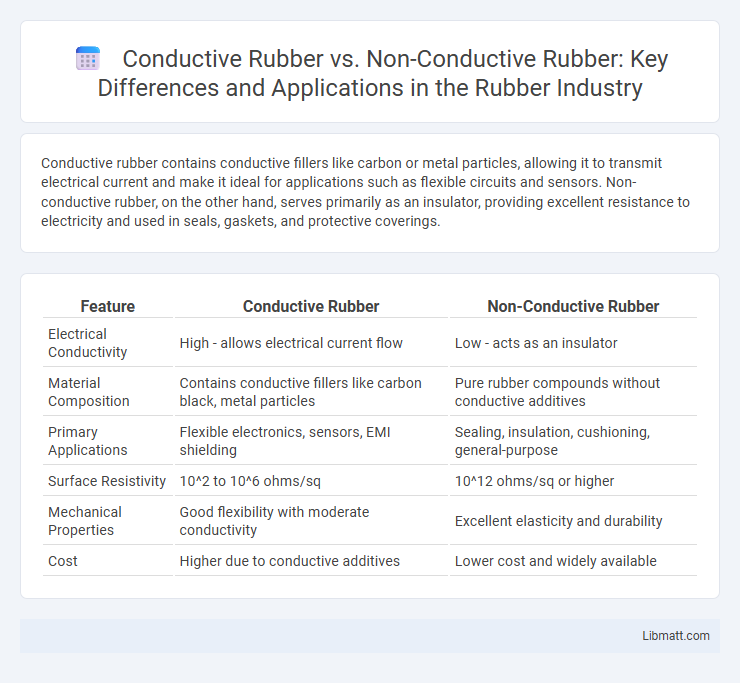

Conductive rubber contains conductive fillers like carbon or metal particles, allowing it to transmit electrical current and make it ideal for applications such as flexible circuits and sensors. Non-conductive rubber, on the other hand, serves primarily as an insulator, providing excellent resistance to electricity and used in seals, gaskets, and protective coverings.

Table of Comparison

| Feature | Conductive Rubber | Non-Conductive Rubber |

|---|---|---|

| Electrical Conductivity | High - allows electrical current flow | Low - acts as an insulator |

| Material Composition | Contains conductive fillers like carbon black, metal particles | Pure rubber compounds without conductive additives |

| Primary Applications | Flexible electronics, sensors, EMI shielding | Sealing, insulation, cushioning, general-purpose |

| Surface Resistivity | 10^2 to 10^6 ohms/sq | 10^12 ohms/sq or higher |

| Mechanical Properties | Good flexibility with moderate conductivity | Excellent elasticity and durability |

| Cost | Higher due to conductive additives | Lower cost and widely available |

Introduction to Conductive and Non-Conductive Rubber

Conductive rubber contains carbon or metal fillers that enable the flow of electricity, making it suitable for applications requiring electrical conductivity or static dissipation. Non-conductive rubber, in contrast, is an insulating material designed to prevent electrical current from passing through, often used in sealing, cushioning, and protecting components. Understanding the differences in electrical properties helps you choose the appropriate rubber type for electronics, gasketing, or safety solutions.

Key Properties of Conductive Rubber

Conductive rubber exhibits exceptional electrical conductivity due to the incorporation of conductive fillers such as carbon black, graphite, or metal particles, enabling its use in applications requiring static dissipation or electromagnetic interference shielding. Its flexibility, durability, and resistance to environmental factors make it suitable for flexible circuits, sensors, and wearable electronics. Unlike non-conductive rubber, which primarily provides insulation and mechanical cushioning, conductive rubber balances electrical performance with mechanical resilience.

Key Properties of Non-Conductive Rubber

Non-conductive rubber exhibits excellent electrical insulation properties, high flexibility, and strong resistance to environmental factors such as moisture, chemicals, and temperature variations. Its low electrical conductivity makes it ideal for applications requiring safety from electrical hazards and effective insulation. Common types include silicone, neoprene, and EPDM, widely used in seals, gaskets, and protective coverings.

Material Composition Differences

Conductive rubber contains conductive fillers such as carbon black, silver, or nickel particles embedded within its polymer matrix, enabling electrical conductivity. Non-conductive rubber lacks these fillers, consisting primarily of insulating polymers like natural rubber or silicone, resulting in electrical resistance. The dispersion and concentration of conductive materials in conductive rubber directly influence its electrical and mechanical properties compared to its non-conductive counterpart.

Electrical Conductivity Comparison

Conductive rubber is engineered with conductive fillers like carbon black or metal particles, enabling it to transmit electrical signals, whereas non-conductive rubber lacks these fillers and acts as an insulator. Your choice depends on whether you need electrical conductivity for applications such as EMI shielding, sensors, or flexible circuits, where conductive rubber excels. Non-conductive rubber is ideal for insulation and protective covers, providing resistance against electrical currents and preventing short circuits.

Typical Applications of Conductive Rubber

Conductive rubber is commonly used in applications requiring electrostatic discharge (ESD) protection, electromagnetic interference (EMI) shielding, and flexible electrical contacts, such as in keyboards, wearable electronics, and medical devices. Its ability to conduct electricity makes it ideal for sensors, switches, and flexible circuit components in automotive and consumer electronics industries. Non-conductive rubber, by contrast, is preferred for insulation, sealing, and vibration damping where electrical conductivity is undesired.

Typical Applications of Non-Conductive Rubber

Non-conductive rubber is widely used in insulating applications such as electrical cable jackets, protective gloves, and rubber gaskets, where preventing electrical conductivity is essential for safety. It is also common in automotive seals, vibration dampers, and medical devices due to its excellent resistance to chemicals and flexibility. Typical materials include natural rubber, silicone rubber, and EPDM, chosen for their high dielectric strength and durability.

Advantages and Limitations of Each Type

Conductive rubber offers excellent electrical conductivity and is ideal for applications requiring static dissipation or EMI shielding, but it may have limited mechanical strength and higher cost compared to non-conductive types. Non-conductive rubber provides superior insulation, flexibility, and durability, making it suitable for sealing and cushioning purposes, yet it lacks the ability to conduct electricity. Your choice depends on whether electrical performance or physical resilience is the priority in your specific application.

Selection Criteria for Specific Uses

Selecting between conductive rubber and non-conductive rubber depends on the electrical requirements and environmental conditions of your application. Conductive rubber is ideal for applications requiring electrostatic discharge protection or electromagnetic interference shielding, while non-conductive rubber excels in insulation, sealing, and cushioning where electrical conductivity is undesirable. Material properties such as conductivity level, durability, chemical resistance, and flexibility should be analyzed to match the specific use-case demands effectively.

Future Trends in Rubber Technology

Future trends in rubber technology emphasize the advancement of conductive rubber with enhanced electrical conductivity for applications in flexible electronics, wearable devices, and energy storage systems. Innovations include the integration of nanomaterials like graphene and carbon nanotubes to improve conductivity and mechanical properties while maintaining flexibility and durability. Non-conductive rubber continues to evolve with bio-based formulations and superior chemical resistance, targeting automotive, aerospace, and industrial sealing applications.

Conductive Rubber vs Non-Conductive Rubber Infographic

libmatt.com

libmatt.com