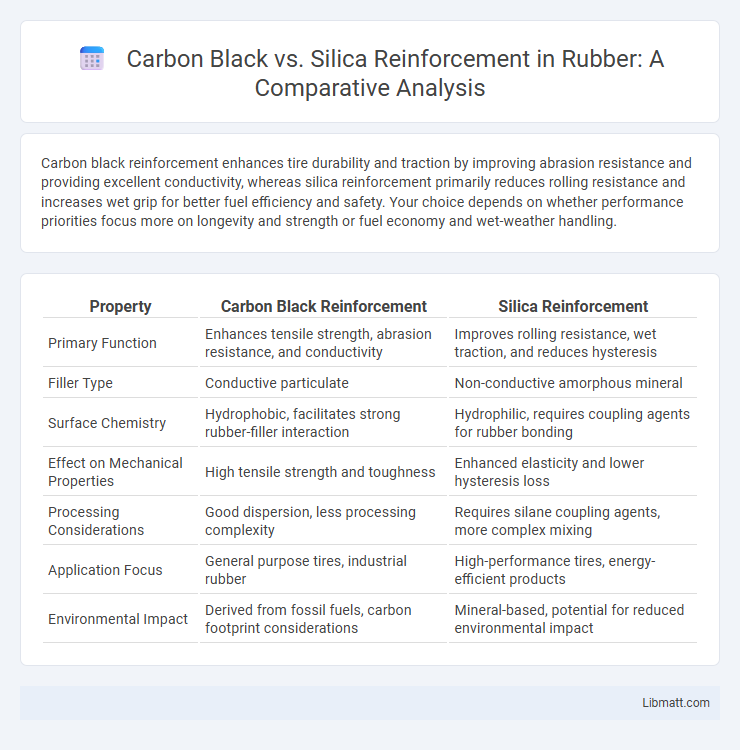

Carbon black reinforcement enhances tire durability and traction by improving abrasion resistance and providing excellent conductivity, whereas silica reinforcement primarily reduces rolling resistance and increases wet grip for better fuel efficiency and safety. Your choice depends on whether performance priorities focus more on longevity and strength or fuel economy and wet-weather handling.

Table of Comparison

| Property | Carbon Black Reinforcement | Silica Reinforcement |

|---|---|---|

| Primary Function | Enhances tensile strength, abrasion resistance, and conductivity | Improves rolling resistance, wet traction, and reduces hysteresis |

| Filler Type | Conductive particulate | Non-conductive amorphous mineral |

| Surface Chemistry | Hydrophobic, facilitates strong rubber-filler interaction | Hydrophilic, requires coupling agents for rubber bonding |

| Effect on Mechanical Properties | High tensile strength and toughness | Enhanced elasticity and lower hysteresis loss |

| Processing Considerations | Good dispersion, less processing complexity | Requires silane coupling agents, more complex mixing |

| Application Focus | General purpose tires, industrial rubber | High-performance tires, energy-efficient products |

| Environmental Impact | Derived from fossil fuels, carbon footprint considerations | Mineral-based, potential for reduced environmental impact |

Introduction to Tire Reinforcement Fillers

Carbon black reinforcement and silica reinforcement are essential fillers widely used in tire manufacturing to enhance performance and durability. Carbon black provides superior abrasion resistance, tensile strength, and heat dissipation, making it ideal for heavy-duty and high-strength tires. Silica reinforcement improves rolling resistance and wet traction while reducing fuel consumption and emissions, offering significant advantages in eco-friendly tire designs.

Overview of Carbon Black in Rubber Compounds

Carbon black is a highly effective reinforcing filler in rubber compounds, enhancing tensile strength, abrasion resistance, and durability. Its fine particle size and large surface area improve the rubber's mechanical properties and contribute to better conductivity and UV protection. Compared to silica reinforcement, carbon black offers superior reinforcement in terms of tensile strength and wear resistance, making it ideal for tire manufacturing and heavy-duty rubber applications.

Silica as a Modern Reinforcing Agent

Silica reinforcement is a modern alternative to carbon black in tire manufacturing, offering lower rolling resistance and improved wet traction, which enhances fuel efficiency and safety. Silica particles create stronger bonds with the polymer matrix due to their surface chemistry, leading to better durability and reduced wear. Your choice of silica as a reinforcing agent can significantly improve tire performance and environmental sustainability.

Comparative Structure and Morphology

Carbon black reinforcement features a highly aggregated structure with a large surface area, enhancing filler-polymer interaction and resulting in improved tensile strength and abrasion resistance. Silica reinforcement presents a more discrete, less aggregated morphology with polar surface groups that promote strong filler-matrix bonding when coupled with silane coupling agents, significantly enhancing wet traction and rolling resistance in tires. The distinct structural differences between carbon black and silica fillers influence their dispersion, interfacial compatibility, and ultimately the mechanical and dynamic properties of reinforced rubber composites.

Impact on Mechanical Properties

Carbon black reinforcement significantly enhances tensile strength, abrasion resistance, and fatigue durability in rubber composites due to its strong filler-matrix interaction and uniform dispersion. Silica reinforcement improves hardness, elasticity, and reduces hysteresis, leading to better rolling resistance and wet traction, primarily attributed to its polar surface chemistry and optimized coupling agents. The choice between carbon black and silica fillers directly influences the balance of mechanical properties such as modulus, tear strength, and dynamic performance in elastomer applications.

Influence on Rolling Resistance and Fuel Efficiency

Carbon black reinforcement significantly reduces rolling resistance due to its strong interaction with the rubber matrix, leading to enhanced fuel efficiency in tires. Silica reinforcement also lowers rolling resistance but offers better wet traction and reduced hysteresis, balancing fuel economy and safety. The combined use of carbon black and silica optimizes tire performance by maximizing fuel efficiency while maintaining durability and grip.

Abrasion Resistance: Carbon Black vs Silica

Carbon black reinforcement provides superior abrasion resistance compared to silica reinforcement due to its ability to enhance the toughness and durability of rubber compounds. Silica offers improved wet traction and reduced rolling resistance but typically results in lower abrasion resistance because of its weaker filler-rubber interaction. In high-wear applications, carbon black is preferred to achieve extended tire tread life and enhanced resistance to surface degradation.

Processing and Mixing Considerations

Carbon black reinforcement requires careful dispersion during mixing to prevent agglomeration, which can affect the final compound's mechanical properties. Silica reinforcement demands the use of coupling agents like silanes to enhance compatibility with the polymer matrix, improving dispersion and reducing processing torque. Your choice will impact mixing time, energy consumption, and equipment wear, influencing overall manufacturing efficiency.

Environmental and Sustainability Factors

Carbon black reinforcement in rubber products generates higher CO2 emissions and relies heavily on fossil fuels, posing greater environmental challenges compared to silica, which is derived from abundant natural sources and often produced with lower energy consumption. Silica reinforcement enhances tire rolling resistance and fuel efficiency, contributing to reduced greenhouse gas emissions throughout the product lifecycle. The recyclability and biodegradability of silica-reinforced materials further support sustainability goals, making silica a preferred choice for eco-friendly applications in tire manufacturing and rubber goods.

Future Trends in Reinforcement Technologies

Carbon black reinforcement is expected to evolve with advanced nano-structured variants offering improved durability and wear resistance in tires and rubber products. Silica reinforcement technology is advancing through research on surface modification techniques to enhance filler dispersion and interaction with polymer matrices, leading to lower rolling resistance and better fuel efficiency. You can anticipate hybrid reinforcement systems combining carbon black and silica to optimize mechanical performance and sustainability in future material applications.

Carbon Black Reinforcement vs Silica Reinforcement Infographic

libmatt.com

libmatt.com