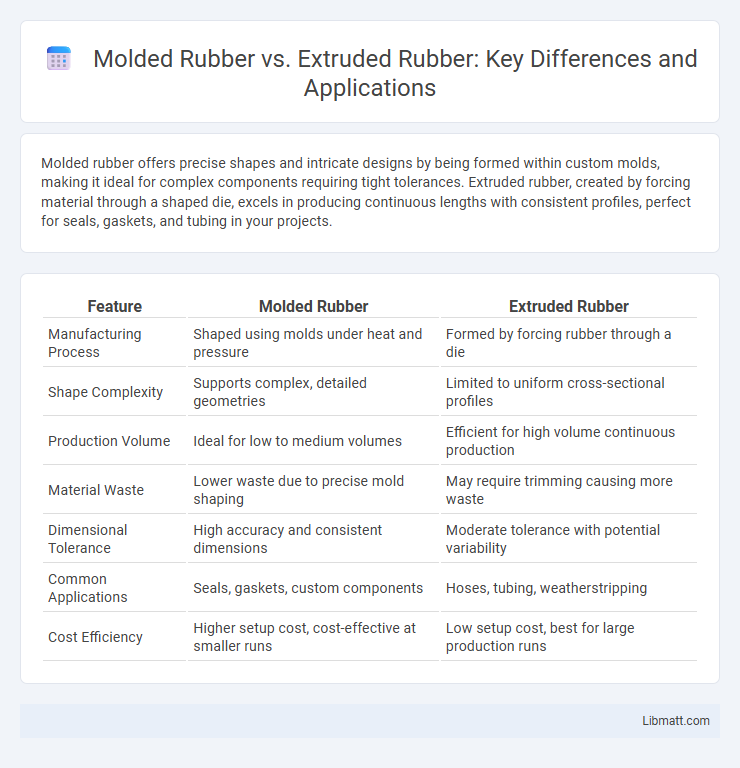

Molded rubber offers precise shapes and intricate designs by being formed within custom molds, making it ideal for complex components requiring tight tolerances. Extruded rubber, created by forcing material through a shaped die, excels in producing continuous lengths with consistent profiles, perfect for seals, gaskets, and tubing in your projects.

Table of Comparison

| Feature | Molded Rubber | Extruded Rubber |

|---|---|---|

| Manufacturing Process | Shaped using molds under heat and pressure | Formed by forcing rubber through a die |

| Shape Complexity | Supports complex, detailed geometries | Limited to uniform cross-sectional profiles |

| Production Volume | Ideal for low to medium volumes | Efficient for high volume continuous production |

| Material Waste | Lower waste due to precise mold shaping | May require trimming causing more waste |

| Dimensional Tolerance | High accuracy and consistent dimensions | Moderate tolerance with potential variability |

| Common Applications | Seals, gaskets, custom components | Hoses, tubing, weatherstripping |

| Cost Efficiency | Higher setup cost, cost-effective at smaller runs | Low setup cost, best for large production runs |

Introduction to Molded and Extruded Rubber

Molded rubber is produced by injecting or compression molding rubber compounds into precise shapes using molds, ideal for complex geometries and high-volume production. Extruded rubber is created by forcing rubber material through a die to form continuous profiles such as seals, tubes, and gaskets, offering consistent cross-sections and efficient lengths. Understanding these fundamental manufacturing processes helps determine the best application based on design complexity and production requirements.

Understanding the Rubber Manufacturing Process

Molded rubber involves shaping raw rubber compounds within a heated mold cavity to achieve complex, precise components used in automotive, aerospace, and medical industries. Extruded rubber is produced by forcing rubber material through a die to create continuous profiles such as seals, gaskets, and tubing, enabling efficient production of uniform cross-sections. Understanding these manufacturing methods highlights the trade-off between design flexibility in molding and the cost-effective, consistent output of extrusion processes.

Key Differences Between Molded and Extruded Rubber

Molded rubber is shaped by injecting or compressing rubber into a mold cavity, allowing for complex, three-dimensional parts with precise dimensions and intricate details. Extruded rubber is produced by forcing rubber material through a die to create continuous profiles with consistent cross-sections, ideal for seals, gaskets, and tubing. Key differences include the manufacturing process, complexity of shapes, production volume efficiency, and typical applications, with molded rubber suited for custom, intricate parts and extruded rubber best for uniform, long lengths.

Benefits of Molded Rubber Components

Molded rubber components offer superior precision and consistency compared to extruded rubber, enabling complex shapes and intricate designs tailored to specific applications. Their enhanced durability and resistance to wear, chemicals, and extreme temperatures make them ideal for high-performance industries like automotive and aerospace. Choosing molded rubber ensures your parts have better sealing capabilities, reduced waste, and longer service life, ultimately improving product reliability and cost-efficiency.

Advantages of Extruded Rubber Products

Extruded rubber products offer consistent cross-sectional profiles and superior dimensional accuracy, making them ideal for applications requiring continuous lengths and uniform shapes. Their production process allows for faster manufacturing and cost-efficiency, reducing waste and enabling customization in hardness and flexibility. You can benefit from the versatility of extruded rubber in sealing, gasketing, and protective components across various industries.

Common Applications for Molded Rubber

Molded rubber is extensively used in automotive parts, sealing components, and vibration dampening due to its ability to form complex shapes and achieve precise tolerances. Its applications often include gaskets, O-rings, and custom-made protective covers in aerospace and industrial machinery. Your choice of molded rubber ensures durability and flexibility for specialized products requiring consistent performance under stress.

Typical Uses of Extruded Rubber

Extruded rubber is commonly used in applications requiring consistent cross-sectional profiles such as seals, gaskets, weather stripping, and tubing. Its continuous production process allows for long lengths and uniform shapes, making it ideal for automotive door seals, window trims, and hoses. You will find extruded rubber essential for projects needing flexibility and precise dimensions in industrial and commercial settings.

Performance and Durability Comparison

Molded rubber offers superior performance with precise shapes and tight tolerances, enhancing durability in high-impact and complex applications. Extruded rubber provides consistent cross-sections ideal for sealing and insulation, exhibiting strong resistance to wear and environmental factors but may lack the intricate design capabilities of molded options. Both types deliver excellent durability, though molded rubber typically withstands higher stress and longer service life under demanding conditions.

Cost Considerations: Molded vs Extruded Rubber

Molded rubber typically incurs higher upfront costs due to the expense of creating custom molds and longer production setup times, making it ideal for complex or high-precision parts. Extruded rubber, with its continuous production process and minimal tooling requirements, offers lower initial costs and is more cost-effective for producing simple, uniform profiles in large volumes. Your choice between molded and extruded rubber should factor in production volume, part design complexity, and budget constraints to optimize overall cost efficiency.

Choosing the Right Solution for Your Project

Molded rubber offers precise shapes and complex geometries ideal for projects requiring detailed design and high durability, while extruded rubber provides continuous profiles suitable for seals, gaskets, and dynamic applications. Choosing the right solution depends on your project's complexity, production volume, and performance requirements, ensuring optimal functionality and cost efficiency. Assessing factors like material properties, tolerances, and manufacturing speed will guide you to the best rubber processing method.

Molded Rubber vs Extruded Rubber Infographic

libmatt.com

libmatt.com