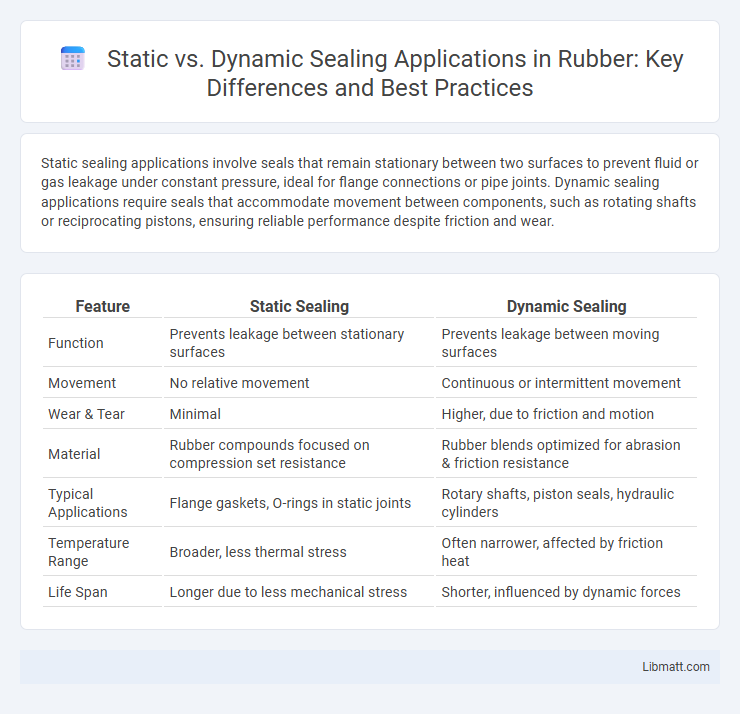

Static sealing applications involve seals that remain stationary between two surfaces to prevent fluid or gas leakage under constant pressure, ideal for flange connections or pipe joints. Dynamic sealing applications require seals that accommodate movement between components, such as rotating shafts or reciprocating pistons, ensuring reliable performance despite friction and wear.

Table of Comparison

| Feature | Static Sealing | Dynamic Sealing |

|---|---|---|

| Function | Prevents leakage between stationary surfaces | Prevents leakage between moving surfaces |

| Movement | No relative movement | Continuous or intermittent movement |

| Wear & Tear | Minimal | Higher, due to friction and motion |

| Material | Rubber compounds focused on compression set resistance | Rubber blends optimized for abrasion & friction resistance |

| Typical Applications | Flange gaskets, O-rings in static joints | Rotary shafts, piston seals, hydraulic cylinders |

| Temperature Range | Broader, less thermal stress | Often narrower, affected by friction heat |

| Life Span | Longer due to less mechanical stress | Shorter, influenced by dynamic forces |

Introduction to Sealing Applications

Static sealing applications are essential for preventing leaks between non-moving surfaces, commonly found in flange connections, pipe joints, and equipment housings. Dynamic sealing applications handle fluid containment in moving parts such as rotating shafts, hydraulic cylinders, and pistons, requiring materials and designs that accommodate motion and pressure variations. Understanding the differences helps you select the right seal for durability and performance in your system.

Defining Static and Dynamic Seals

Static seals prevent leakage between stationary components by maintaining a tight barrier under pressure or temperature changes, commonly used in flange joints and pipe connections. Dynamic seals accommodate relative motion between parts, such as rotation or linear movement, and include designs like O-rings in hydraulic cylinders or rotary shaft seals, ensuring fluid containment during motion. Both types utilize elastomers, metals, or composite materials selected based on application-specific factors like pressure, speed, and temperature.

Key Differences Between Static and Dynamic Seals

Static seals maintain a fixed position and prevent leakage between stationary components, while dynamic seals accommodate relative motion between parts, such as rotation or reciprocation. The key differences include design complexity, material selection, and wear resistance, with dynamic seals requiring more flexible and durable materials to handle continuous movement. Understanding these distinctions ensures your sealing solutions provide optimal performance and longevity in their respective applications.

Common Materials Used in Each Application

Static sealing applications commonly use materials such as elastomers (e.g., Nitrile, Viton, and EPDM), PTFE, and metal gaskets, prized for their ability to maintain a seal under constant pressure without movement. Dynamic sealing applications often require more resilient materials like polyurethane, silicone, and thermoplastic elastomers, designed to withstand friction, wear, and repeated motion. Metal, graphite, and composite seals also find use in dynamic conditions where high temperatures and pressures are involved, balancing durability and flexibility.

Performance Requirements for Static and Dynamic Seals

Static seals require high resistance to pressure and temperature without movement, ensuring leak prevention in fixed joints. Dynamic seals must accommodate motion such as rotation or oscillation, demanding flexibility and durability to maintain sealing integrity under friction and wear. Your selection should consider operating conditions, speed, and environmental factors to match performance needs accurately.

Typical Examples of Static Sealing Applications

Typical examples of static sealing applications include flange gaskets in piping systems, O-rings in hydraulic and pneumatic equipment, and mechanical seals in stationary machine components. These seals prevent leakage between two stationary surfaces under varying pressure and temperature conditions. Materials such as PTFE, rubber, and metal are commonly used to ensure durability and effective sealing performance.

Typical Examples of Dynamic Sealing Applications

Dynamic sealing applications commonly include rotating shafts in pumps, compressors, and mixers where seals must accommodate continuous movement while preventing fluid leakage. Hydraulic cylinders and pneumatic actuators also frequently employ dynamic seals to maintain pressure and fluid integrity during piston motion. These applications demand materials and designs capable of withstanding friction, pressure fluctuations, and temperature variations to ensure reliable performance.

Factors Influencing Seal Selection

Seal selection depends on factors such as pressure, temperature, and movement within the application. Static sealing requires materials that resist deformation under constant load, while dynamic sealing demands flexibility and wear resistance to accommodate motion. Your choice should consider the operating environment, compatibility with fluids, and the mechanical stresses involved to ensure optimal performance and longevity.

Advantages and Limitations of Each Seal Type

Static sealing applications provide reliable, long-lasting containment with minimal movement, making them ideal for flange connections and gaskets under constant pressure. Dynamic sealing, designed for parts with relative motion like rotating shafts or pistons, offers flexibility and accommodates motion but may experience faster wear and require more maintenance. Your choice depends on operational conditions, with static seals favored for stability and durability, while dynamic seals excel in environments needing continuous motion sealing.

Choosing the Right Seal for Your Application

Selecting the right seal for your application depends on understanding the difference between static and dynamic sealing. Static seals prevent leakage between non-moving parts and are ideal for applications with minimal motion, while dynamic seals accommodate motion between components such as rotating shafts or reciprocating pistons. Evaluating factors like pressure, temperature, speed, and fluid type helps ensure your seal delivers optimal performance and longevity in its specific operating environment.

Static vs Dynamic sealing applications Infographic

libmatt.com

libmatt.com