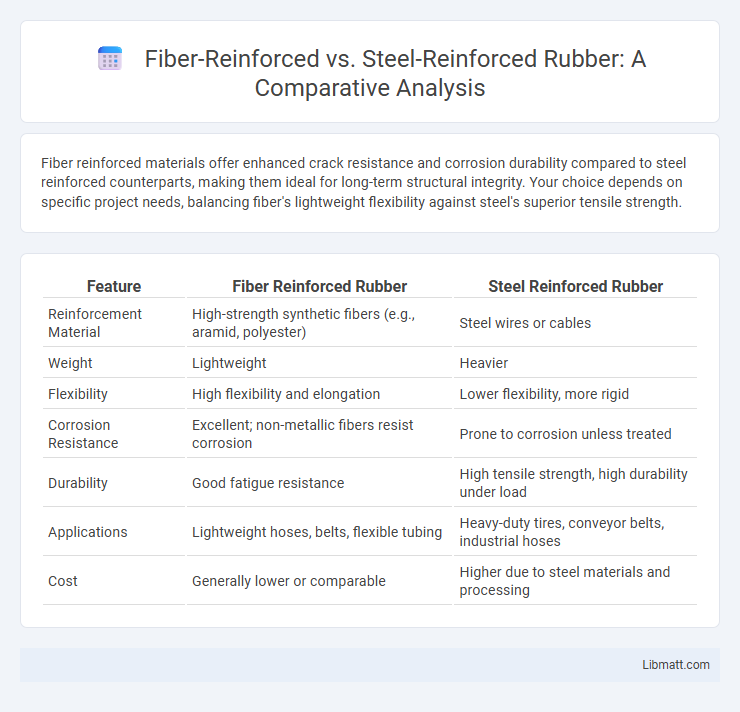

Fiber reinforced materials offer enhanced crack resistance and corrosion durability compared to steel reinforced counterparts, making them ideal for long-term structural integrity. Your choice depends on specific project needs, balancing fiber's lightweight flexibility against steel's superior tensile strength.

Table of Comparison

| Feature | Fiber Reinforced Rubber | Steel Reinforced Rubber |

|---|---|---|

| Reinforcement Material | High-strength synthetic fibers (e.g., aramid, polyester) | Steel wires or cables |

| Weight | Lightweight | Heavier |

| Flexibility | High flexibility and elongation | Lower flexibility, more rigid |

| Corrosion Resistance | Excellent; non-metallic fibers resist corrosion | Prone to corrosion unless treated |

| Durability | Good fatigue resistance | High tensile strength, high durability under load |

| Applications | Lightweight hoses, belts, flexible tubing | Heavy-duty tires, conveyor belts, industrial hoses |

| Cost | Generally lower or comparable | Higher due to steel materials and processing |

Introduction to Reinforced Materials

Fiber reinforced materials, composed of high-strength fibers such as glass, carbon, or aramid embedded in a polymer matrix, offer superior tensile strength, corrosion resistance, and lightweight properties compared to traditional steel reinforcement. Steel reinforcement, widely used in concrete structures, provides excellent compressive strength and ductility but suffers from corrosion and added weight issues. Advancements in fiber reinforced composites have led to enhanced durability and performance in construction, automotive, and aerospace applications where steel's limitations impact long-term structural integrity.

Overview of Fiber Reinforced Concrete

Fiber Reinforced Concrete (FRC) incorporates discrete fibers such as glass, steel, or synthetic materials to enhance tensile strength, ductility, and crack resistance compared to traditional steel reinforced concrete. This composite material improves durability, reduces maintenance costs, and offers superior performance in applications subject to impact, fatigue, and shrinkage stresses. Your construction projects can benefit from FRC's ability to distribute loads more evenly and minimize structural weaknesses typically addressed by conventional steel reinforcement.

Overview of Steel Reinforced Concrete

Steel reinforced concrete combines concrete's compressive strength with steel's tensile strength, creating a composite material widely used in construction for its durability and load-bearing capacity. The steel bars, also known as rebar, are embedded within the concrete to resist tension forces, preventing cracks and structural failures. Your choice of steel reinforcement ensures enhanced stability and longevity in concrete structures, especially in buildings, bridges, and infrastructure projects.

Material Properties and Performance

Fiber reinforced composites exhibit high tensile strength, corrosion resistance, and lightweight properties, making them ideal for structures prone to chemical exposure and requiring enhanced durability. Steel reinforced materials provide superior compressive strength and ductility, offering excellent load-bearing capacity and toughness in construction applications. Performance-wise, fiber reinforcement reduces crack propagation and enhances fatigue resistance, while steel reinforcement excels in withstanding dynamic loads and impact forces.

Durability and Longevity Comparison

Fiber reinforced materials exhibit superior resistance to corrosion, chemical attacks, and environmental degradation, resulting in enhanced durability compared to traditional steel reinforcement. Steel reinforced structures, while known for high tensile strength, often require protective coatings or maintenance to prevent rust and corrosion that can compromise longevity. Choosing fiber reinforcement can extend the lifespan of your construction by minimizing maintenance needs and ensuring sustained structural integrity over time.

Structural Applications and Suitability

Fiber reinforced materials offer superior corrosion resistance and lighter weight, making them ideal for structural applications in harsh environments and long-span constructions. Steel reinforced concrete provides higher tensile strength and ductility, ensuring durability and reliability in load-bearing structures such as bridges and high-rise buildings. Your choice between fiber reinforced and steel reinforced depends on specific project requirements, including environmental conditions and structural load demands.

Cost Analysis: Fiber vs Steel Reinforcement

Fiber reinforced materials often present lower overall costs compared to steel reinforcement due to reduced labor expenses, faster installation times, and decreased maintenance requirements. Steel reinforcement typically incurs higher upfront costs driven by material prices and the need for corrosion protection, which can increase lifecycle expenses. Your project budget can benefit from fiber reinforcement's durability and cost-efficiency, especially in environments prone to corrosion or requiring long-term performance.

Installation Process and Construction Efficiency

Fiber reinforced materials offer a simplified installation process with lighter weight and easier handling, leading to faster construction times and reduced labor costs compared to steel reinforcement. Steel reinforcement requires precise placement and additional support measures to prevent corrosion, often extending installation duration and complexity. Your choice between fiber reinforced and steel reinforced systems directly impacts construction efficiency by balancing speed, durability, and labor requirements.

Environmental Impact and Sustainability

Fiber reinforced materials significantly reduce environmental impact compared to steel reinforced options due to their lower carbon footprint and energy consumption during production. Their corrosion resistance extends structural lifespan, minimizing the need for frequent repairs and replacement, which conserves resources over time. When considering sustainable construction, your choice of fiber reinforcement supports eco-friendly practices by promoting durability and reducing greenhouse gas emissions associated with steel manufacturing.

Choosing the Right Reinforcement: Key Considerations

Choosing the right reinforcement depends on factors like tensile strength, corrosion resistance, and project environment. Fiber reinforced materials offer enhanced durability and lightweight benefits, making them ideal for structures exposed to moisture or chemical exposure. Your decision should balance these properties with cost-efficiency and structural requirements for optimal performance.

Fiber Reinforced vs Steel Reinforced Infographic

libmatt.com

libmatt.com