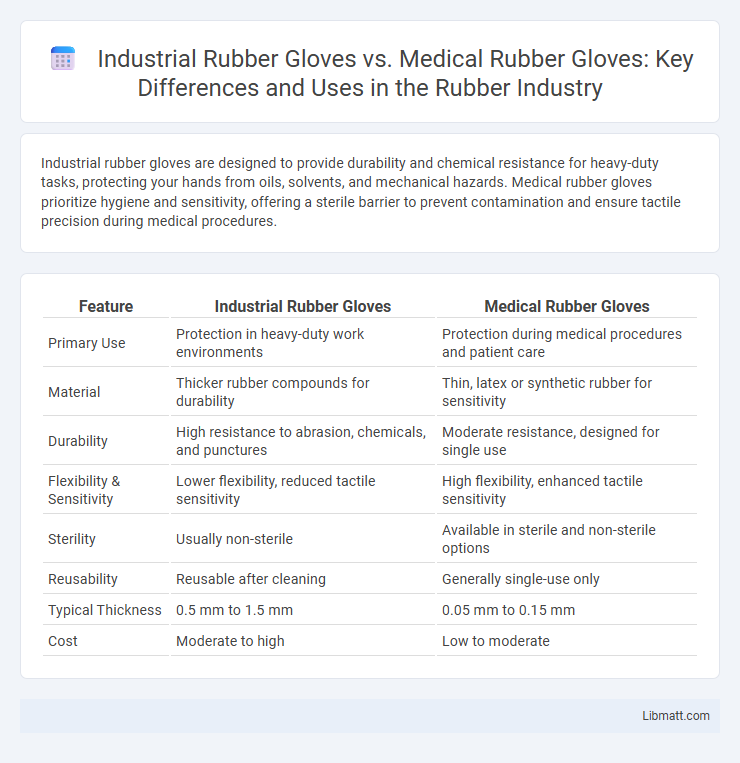

Industrial rubber gloves are designed to provide durability and chemical resistance for heavy-duty tasks, protecting your hands from oils, solvents, and mechanical hazards. Medical rubber gloves prioritize hygiene and sensitivity, offering a sterile barrier to prevent contamination and ensure tactile precision during medical procedures.

Table of Comparison

| Feature | Industrial Rubber Gloves | Medical Rubber Gloves |

|---|---|---|

| Primary Use | Protection in heavy-duty work environments | Protection during medical procedures and patient care |

| Material | Thicker rubber compounds for durability | Thin, latex or synthetic rubber for sensitivity |

| Durability | High resistance to abrasion, chemicals, and punctures | Moderate resistance, designed for single use |

| Flexibility & Sensitivity | Lower flexibility, reduced tactile sensitivity | High flexibility, enhanced tactile sensitivity |

| Sterility | Usually non-sterile | Available in sterile and non-sterile options |

| Reusability | Reusable after cleaning | Generally single-use only |

| Typical Thickness | 0.5 mm to 1.5 mm | 0.05 mm to 0.15 mm |

| Cost | Moderate to high | Low to moderate |

Introduction to Industrial and Medical Rubber Gloves

Industrial rubber gloves are designed to protect workers from chemicals, abrasions, and mechanical hazards in manufacturing, construction, and chemical processing environments. Medical rubber gloves, typically made from latex or nitrile, provide a sterile barrier to prevent contamination and infection during medical procedures and patient care. Both types of gloves prioritize durability and protection, but their materials and specifications differ to meet industry-specific safety standards.

Key Differences in Design and Materials

Industrial rubber gloves are typically made from thicker, more durable materials like nitrile or neoprene to withstand harsh chemicals and mechanical hazards, while medical rubber gloves prioritize latex or nitrile formulations that offer superior sensitivity and flexibility for precise tasks. Industrial gloves often feature reinforced palms and extended cuffs for enhanced protection, whereas medical gloves are designed to minimize allergenic properties and maintain sterility. Understanding these key differences in design and materials helps you select the appropriate gloves for safety and performance in your specific work environment.

Regulatory Standards and Certifications Comparison

Industrial rubber gloves comply with standards such as ASTM D120 and EN 388, ensuring protection against mechanical hazards like cuts and abrasions. Medical rubber gloves must meet FDA 21 CFR 800.20 and ASTM D3578 standards, guaranteeing sterility and protection against biological contaminants. Your choice should depend on the regulatory requirements specific to the gloves' intended application to ensure safety and compliance.

Intended Uses: Industrial vs Medical Applications

Industrial rubber gloves are designed to protect your hands from chemicals, oils, and abrasives found in manufacturing, construction, and mechanical work environments, providing durability and resistance to harsh substances. Medical rubber gloves prioritize sterility, dexterity, and sensitivity for use in healthcare settings, ensuring protection against pathogens and contaminants during examinations and surgical procedures. Understanding the intended use helps you select gloves that offer the appropriate barrier, comfort, and safety specific to either industrial or medical applications.

Protection Levels Against Chemicals and Pathogens

Industrial rubber gloves offer enhanced protection levels against harsh chemicals, oils, and solvents typically encountered in manufacturing and chemical processing environments. Medical rubber gloves provide superior barrier protection against pathogens, viruses, and biological contaminants, crucial for infection control in healthcare settings. Your choice between these gloves should align with the specific exposure risks, ensuring adequate chemical resistance for industrial tasks or pathogen defense in medical use.

Comfort, Fit, and Dexterity Requirements

Industrial rubber gloves are designed for durability and resistance to chemicals or abrasions, often sacrificing some comfort and dexterity to ensure maximum protection in heavy-duty environments. Medical rubber gloves prioritize precision, tactile sensitivity, and a snug fit to facilitate delicate procedures, often using thinner materials that maximize comfort and dexterity. The comfort and fit of industrial gloves cater to prolonged wear in rigorous tasks, while medical gloves emphasize flexibility and tactile feedback for intricate manipulations.

Durability and Resistance to Wear

Industrial rubber gloves offer superior durability and resistance to wear, designed to withstand harsh chemicals, abrasion, and punctures commonly encountered in heavy-duty work environments. Medical rubber gloves prioritize barrier protection and sensitivity but may sacrifice some durability to maintain flexibility and comfort during extended use. Your choice depends on balancing the need for long-lasting wear in industrial settings versus the high-touch, contamination-sensitive requirements of medical applications.

Cost Considerations and Affordability

Industrial rubber gloves generally cost less due to bulk manufacturing and lower material specifications compared to medical rubber gloves, which require stringent quality controls and regulatory compliance. Medical gloves often incur higher expenses because of their sterility, biocompatibility standards, and certification from bodies like FDA or CE, increasing overall affordability challenges for healthcare facilities. Choosing between the two depends on budget constraints, with industrial gloves favored for cost-effective protection in non-clinical environments and medical gloves prioritized where infection control is critical.

Environmental Impact and Disposal Methods

Industrial rubber gloves often contain additives and chemicals that complicate recycling and disposal, leading to increased environmental pollution compared to medical rubber gloves designed for single-use and safe incineration. Medical gloves, typically made from nitrile or latex, are disposed of as biohazard waste, requiring specialized treatment to prevent pathogen transmission, whereas industrial gloves may be discarded in general waste streams, contributing to landfill accumulation. Biodegradable alternatives for both types are emerging but remain limited in adoption due to cost and performance concerns.

Choosing the Right Glove for Your Needs

Industrial rubber gloves are designed for heavy-duty tasks, offering superior resistance to chemicals, abrasion, and punctures, making them ideal for construction, manufacturing, and automotive industries. Medical rubber gloves prioritize hygiene, sensitivity, and protection against pathogens, using materials like latex, nitrile, or vinyl to ensure safety in healthcare and laboratory settings. Selecting the right glove depends on balancing durability and tactile sensitivity with the specific protection requirements dictated by your working environment.

Industrial rubber gloves vs Medical rubber gloves Infographic

libmatt.com

libmatt.com