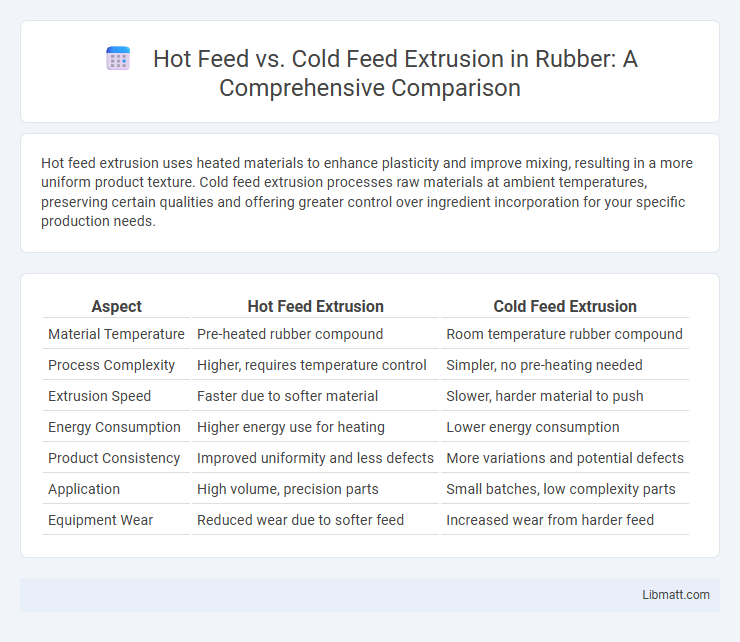

Hot feed extrusion uses heated materials to enhance plasticity and improve mixing, resulting in a more uniform product texture. Cold feed extrusion processes raw materials at ambient temperatures, preserving certain qualities and offering greater control over ingredient incorporation for your specific production needs.

Table of Comparison

| Aspect | Hot Feed Extrusion | Cold Feed Extrusion |

|---|---|---|

| Material Temperature | Pre-heated rubber compound | Room temperature rubber compound |

| Process Complexity | Higher, requires temperature control | Simpler, no pre-heating needed |

| Extrusion Speed | Faster due to softer material | Slower, harder material to push |

| Energy Consumption | Higher energy use for heating | Lower energy consumption |

| Product Consistency | Improved uniformity and less defects | More variations and potential defects |

| Application | High volume, precision parts | Small batches, low complexity parts |

| Equipment Wear | Reduced wear due to softer feed | Increased wear from harder feed |

Introduction to Extrusion Processes

Hot feed extrusion involves processing materials at elevated temperatures, allowing for better plasticization and easier shaping, while cold feed extrusion processes materials at lower or ambient temperatures to maintain structural integrity. These extrusion methods differ primarily in temperature control, affecting the physical properties and applications of the final product. Selecting between hot and cold feed extrusion depends on factors like material type, desired product characteristics, and processing efficiency.

Defining Hot Feed Extrusion

Hot feed extrusion involves the process of feeding pre-heated or thermally conditioned material into the extruder, where it is further melted and shaped under controlled temperature and pressure conditions. This method enhances the homogeneity and flow characteristics of the material, leading to improved product consistency and reduced energy consumption during processing. Hot feed extrusion is commonly used in industries such as food production, pharmaceuticals, and plastics manufacturing to optimize the texture, density, and mechanical properties of extruded products.

Overview of Cold Feed Extrusion

Cold feed extrusion involves feeding solid, dry materials like pellets or granules into the extruder without preheating them, allowing the machine's mechanical energy to melt and shape the product. This process offers precise control over temperature and shear, resulting in consistent product quality suitable for materials sensitive to heat. Your manufacturing efficiency can improve with cold feed extrusion by reducing energy consumption and minimizing thermal degradation during processing.

Key Differences Between Hot Feed and Cold Feed Extrusion

Hot feed extrusion involves preheating the material before it enters the extruder, resulting in reduced viscosity and enhanced flow properties that facilitate shaping complex profiles. Cold feed extrusion processes the raw material at ambient temperatures, preserving its integrity for materials sensitive to heat, but may require higher pressure to form the desired product. Key differences include temperature conditions, material behavior during extrusion, and energy consumption, with hot feed extrusion typically offering improved throughput and surface finish compared to cold feed extrusion.

Advantages of Hot Feed Extrusion

Hot feed extrusion offers enhanced material flow and reduced energy consumption by processing preheated materials, leading to improved product consistency and higher throughput rates. The elevated temperature during extrusion minimizes wear on equipment and allows for better mixing and dispersion of ingredients, which is particularly beneficial in polymer and food industries. Your production efficiency can significantly increase due to faster cycle times and lower operational costs associated with hot feed extrusion systems.

Benefits of Cold Feed Extrusion

Cold feed extrusion offers significant benefits including improved temperature control, which reduces the risk of material degradation and preserves nutrient integrity in sensitive ingredients. This process enhances product consistency by allowing precise control over feed rates and pressure, leading to uniform pellet size and texture. Furthermore, cold feed extrusion supports energy efficiency since it operates at lower temperatures compared to hot feed extrusion, reducing overall production costs.

Material Compatibility and Selection

Hot feed extrusion suits thermoplastics and elastomers, enabling better mixing and flow with materials sensitive to heat, while cold feed extrusion is ideal for powders and granules that may degrade at higher temperatures. Your material's thermal stability and viscosity determine the best extrusion method, ensuring optimal compatibility and product quality. Proper selection enhances processing efficiency and minimizes defects in the final product.

Industrial Applications of Hot Feed and Cold Feed Extrusion

Hot feed extrusion is widely used in the food and pharmaceutical industries for processing heat-sensitive materials, offering precise control over moisture and temperature to enhance product quality. Cold feed extrusion excels in plastics and rubber manufacturing, where it enables the continuous shaping of thermoplastic materials without preheating, preserving material integrity and reducing energy consumption. Your choice between hot feed and cold feed extrusion depends on the specific industrial application and material properties required for optimal production efficiency.

Energy Efficiency and Cost Considerations

Hot feed extrusion typically consumes more energy due to the additional heating requirements, but it often results in improved product quality and faster processing times. Cold feed extrusion uses less energy since it relies on the natural temperature of materials, lowering operational costs, though it may require more frequent maintenance and slower throughput. Your choice should balance energy efficiency with production speed and cost implications to optimize overall extrusion performance.

Choosing the Right Extrusion Method

Selecting the right extrusion method depends on the product's sensitivity to heat and moisture content; hot feed extrusion offers high-temperature processing ideal for moisture reduction and starch gelatinization, while cold feed extrusion operates at lower temperatures preserving heat-sensitive nutrients. Hot feed extrusion is suitable for producing expanded snacks and pellets, optimizing texture and digestibility, whereas cold feed extrusion excels in retaining bioactive compounds and producing dense, nutrient-rich feeds. Evaluating feed material properties and desired product outcomes ensures optimal process efficiency and product quality.

Hot Feed vs Cold Feed Extrusion Infographic

libmatt.com

libmatt.com