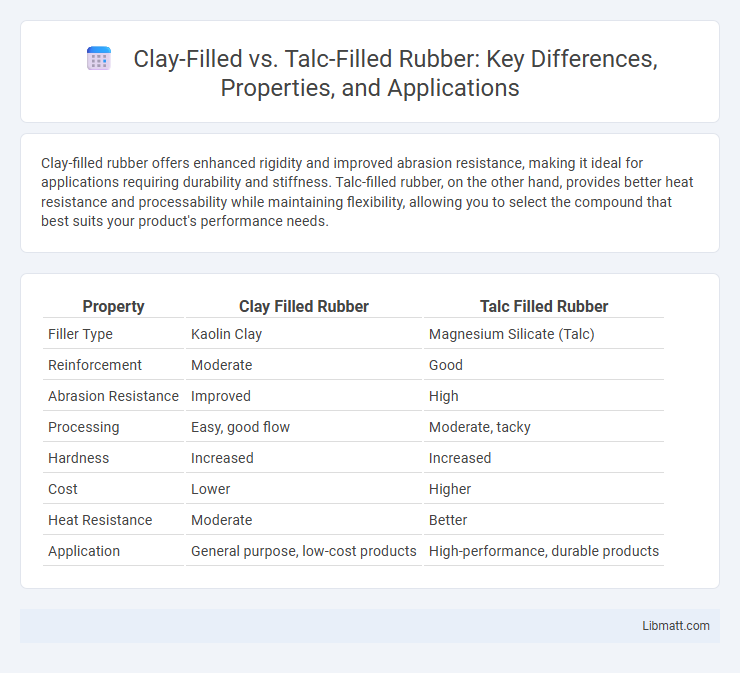

Clay-filled rubber offers enhanced rigidity and improved abrasion resistance, making it ideal for applications requiring durability and stiffness. Talc-filled rubber, on the other hand, provides better heat resistance and processability while maintaining flexibility, allowing you to select the compound that best suits your product's performance needs.

Table of Comparison

| Property | Clay Filled Rubber | Talc Filled Rubber |

|---|---|---|

| Filler Type | Kaolin Clay | Magnesium Silicate (Talc) |

| Reinforcement | Moderate | Good |

| Abrasion Resistance | Improved | High |

| Processing | Easy, good flow | Moderate, tacky |

| Hardness | Increased | Increased |

| Cost | Lower | Higher |

| Heat Resistance | Moderate | Better |

| Application | General purpose, low-cost products | High-performance, durable products |

Introduction to Filled Rubber Compounds

Filled rubber compounds incorporate reinforcing fillers such as clay or talc to enhance mechanical properties and thermal stability in elastomer applications. Clay-filled rubber offers improved abrasion resistance and tensile strength due to its fine particle size and layered silicate structure, while talc-filled rubber provides better dimensional stability and reduced shrinkage owing to talc's plate-like morphology and hydrophobic nature. Selection between clay and talc fillers depends on specific performance requirements, processing conditions, and cost-effectiveness in applications ranging from automotive seals to industrial hoses.

Overview of Clay Filled Rubber

Clay filled rubber incorporates finely ground natural clay as a reinforcing filler, enhancing stiffness and abrasion resistance while maintaining cost-effectiveness. This type of rubber provides moderate improvement in tensile strength and heat resistance compared to unfilled rubber but generally offers lower performance than talc filled rubber. Clay fillers contribute to better processing characteristics, making clay filled rubber suitable for applications in automotive parts, seals, and hoses requiring balanced mechanical properties.

Overview of Talc Filled Rubber

Talc filled rubber offers enhanced rigidity and improved dimensional stability compared to clay filled rubber, making it ideal for applications requiring higher mechanical strength and heat resistance. The fine, lamellar structure of talc increases stiffness while reducing shrinkage and enhancing surface finish, contributing to superior performance in automotive and industrial components. Your choice of talc filled rubber ensures better wear resistance and improved processing characteristics, especially for reinforced flexible items.

Comparative Physical Properties

Clay filled rubber exhibits higher tensile strength and improved abrasion resistance compared to talc filled rubber, making it suitable for heavy-duty applications. Talc filled rubber offers superior thermal stability and enhanced flexibility at lower temperatures, which benefits dynamic performance in cold environments. Both fillers influence the hardness and compression set, but clay typically results in increased stiffness while talc maintains better elasticity.

Impact on Rubber Processing

Clay filled rubber enhances processing by improving compound viscosity and reducing extrusion swell, which leads to smoother processing and better dimensional stability. Talc filled rubber offers superior heat resistance and improved mold release properties, aiding in faster cycle times and reduced defects during molding. Both fillers influence curing characteristics, with talc often accelerating vulcanization and clay providing reinforcement without significantly altering cure rates.

Mechanical Strength Differences

Clay filled rubber typically exhibits lower mechanical strength compared to talc filled rubber due to clay's larger particle size and weaker interfacial bonding. Talc filled rubber enhances tensile strength and abrasion resistance because the finer talc particles promote better stress distribution and improved filler-rubber interaction. Selecting talc filled rubber can optimize your product's durability and mechanical performance in demanding applications.

Cost Efficiency Analysis

Clay filled rubber offers a cost-effective solution due to the lower price of clay compared to talc, significantly reducing material expenses in large-volume production. Talc filled rubber, while slightly more expensive, provides better reinforcement and improved mechanical properties, potentially lowering overall costs by enhancing durability and extending product lifespan. Balancing immediate material savings with long-term performance benefits is crucial when conducting a cost efficiency analysis between clay and talc filled rubber compounds.

Application Suitability

Clay filled rubber offers enhanced reinforcement and abrasion resistance, making it suitable for applications requiring durability in automotive tires and heavy-duty hoses. Talc filled rubber provides improved processing characteristics and better stiffness, ideal for seals, gaskets, and flexible automotive parts. Your choice depends on whether you prioritize mechanical strength or ease of fabrication in the specific application.

Environmental and Health Considerations

Clay-filled rubber compounds exhibit lower environmental impact due to their natural origin and reduced toxicity compared to talc-filled rubber, which may contain asbestos-like impurities posing inhalation risks during processing. Talc's fine particulate nature raises concerns for respiratory health, especially in manufacturing settings lacking adequate ventilation or protective measures. Choosing clay as a filler improves sustainability and occupational safety while maintaining material performance in various rubber applications.

Choosing the Right Filler for Rubber Products

Clay filled rubber offers improved tensile strength and abrasion resistance due to the fine particle size of clay, making it ideal for applications requiring durability. Talc filled rubber enhances rigidity and heat resistance while also providing excellent dimensional stability, which suits products exposed to higher temperatures. When choosing the right filler for your rubber products, consider the specific performance needs such as flexibility, thermal stability, and cost-effectiveness to achieve optimal results.

Clay filled vs Talc filled rubber Infographic

libmatt.com

libmatt.com