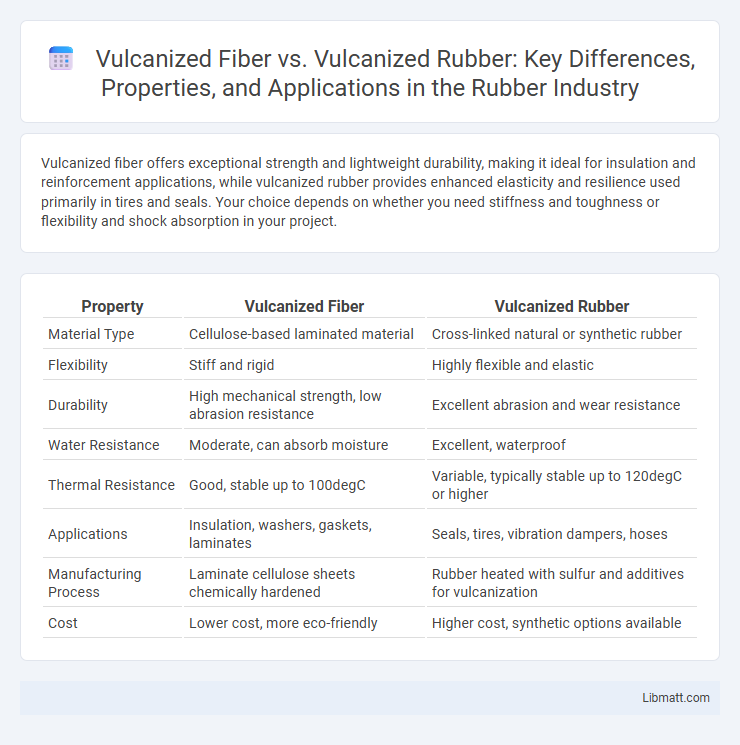

Vulcanized fiber offers exceptional strength and lightweight durability, making it ideal for insulation and reinforcement applications, while vulcanized rubber provides enhanced elasticity and resilience used primarily in tires and seals. Your choice depends on whether you need stiffness and toughness or flexibility and shock absorption in your project.

Table of Comparison

| Property | Vulcanized Fiber | Vulcanized Rubber |

|---|---|---|

| Material Type | Cellulose-based laminated material | Cross-linked natural or synthetic rubber |

| Flexibility | Stiff and rigid | Highly flexible and elastic |

| Durability | High mechanical strength, low abrasion resistance | Excellent abrasion and wear resistance |

| Water Resistance | Moderate, can absorb moisture | Excellent, waterproof |

| Thermal Resistance | Good, stable up to 100degC | Variable, typically stable up to 120degC or higher |

| Applications | Insulation, washers, gaskets, laminates | Seals, tires, vibration dampers, hoses |

| Manufacturing Process | Laminate cellulose sheets chemically hardened | Rubber heated with sulfur and additives for vulcanization |

| Cost | Lower cost, more eco-friendly | Higher cost, synthetic options available |

Introduction to Vulcanized Fiber and Vulcanized Rubber

Vulcanized fiber is a laminated material made by chemically treating cellulose fibers, resulting in a lightweight, durable, and electrically insulating product often used in gaskets, electrical components, and protective coverings. Vulcanized rubber undergoes a chemical process called vulcanization, where raw rubber is heated with sulfur to enhance its elasticity, strength, and resistance to heat and chemicals, making it ideal for tires, seals, and hoses. Your choice between these materials depends on the required mechanical properties, flexibility, and application environment.

Historical Background and Development

Vulcanized fiber originated in the late 19th century as a durable laminated material used primarily for electrical insulation and luggage due to its lightweight and toughness. Vulcanized rubber, developed by Charles Goodyear in 1839, revolutionized industries by enhancing natural rubber's elasticity and resilience through a sulfur curing process. Your understanding of these materials' distinct historical paths highlights vulcanized fiber's role in mechanical applications and vulcanized rubber's dominance in flexible, elastic products.

Manufacturing Processes Compared

Vulcanized fiber is produced by chemically treating layers of cellulose fiber with zinc chloride, which causes the fibers to fuse into a dense, durable material without melting, while vulcanized rubber undergoes a chemical process where natural or synthetic rubber is heated with sulfur to create cross-linked bonds, enhancing elasticity and strength. The key difference lies in vulcanized fiber being a rigid, laminated composite created through chemical immersion and pressing, whereas vulcanized rubber is a flexible elastomer formed through heat and sulfur vulcanization. Understanding these manufacturing processes helps you choose the right material for applications requiring either toughness and insulation or flexibility and resilience.

Key Material Properties

Vulcanized fiber offers exceptional toughness, lightweight durability, and electrical insulation, making it ideal for structural and electrical applications. Vulcanized rubber provides superior elasticity, abrasion resistance, and waterproofing, suited for seals, gaskets, and flexible components. Understanding these key material properties helps you select the right material based on strength, flexibility, and environmental resistance requirements.

Typical Applications and Uses

Vulcanized fiber is commonly used in electrical insulation, washers, and gaskets due to its lightweight, rigid, and durable properties. Vulcanized rubber finds typical applications in automotive tires, seals, hoses, and vibration dampening because of its elasticity and resilience. Understanding the distinct uses helps you choose the right material for mechanical, electrical, or industrial needs.

Strengths and Weaknesses

Vulcanized fiber offers exceptional tensile strength, rigidity, and insulation properties, making it ideal for electrical and mechanical applications, but it lacks flexibility and is susceptible to moisture damage. Vulcanized rubber provides superior elasticity, durability, and resistance to abrasion, chemicals, and weathering, which is advantageous for seals, gaskets, and flexible components, though it has lower tensile strength compared to fiber. Both materials serve distinct roles depending on the application's need for rigidity versus flexibility, with durability factors varying based on environmental exposure.

Performance in Various Environments

Vulcanized fiber exhibits excellent electrical insulation and mechanical strength, making it ideal for dry, moderate environments where lightweight durability is crucial. Vulcanized rubber offers superior flexibility, elasticity, and resistance to water, chemicals, and extreme temperatures, performing well in harsh, wet, or outdoor conditions. The choice between the two depends on environmental stressors such as moisture, temperature fluctuations, and mechanical wear requirements.

Cost and Availability

Vulcanized fiber generally costs less than vulcanized rubber due to its simpler production process and availability of raw materials like cellulose, making it an economical choice for applications requiring lightweight and insulating materials. Vulcanized rubber is more expensive because it undergoes a complex sulfur curing process and uses synthetic or natural rubber, which can be subject to market fluctuations and supply chain constraints. Both materials are widely available, but vulcanized rubber has broader industrial use, often ensuring more consistent availability worldwide compared to the more specialized vulcanized fiber.

Sustainability and Environmental Impact

Vulcanized fiber offers a more sustainable option than vulcanized rubber due to its biodegradable cellulose fiber composition, reducing long-term environmental pollution. Vulcanized rubber, derived from synthetic or natural rubber treated with sulfur, poses recycling challenges and contributes to persistent waste in landfills. Choosing vulcanized fiber supports eco-friendly manufacturing and efficient waste management by minimizing reliance on non-biodegradable materials.

Choosing the Right Material for Your Needs

Vulcanized fiber offers exceptional electrical insulation and mechanical strength, making it ideal for lightweight structural applications and electrical components. Vulcanized rubber provides superior elasticity, durability, and resistance to abrasion, perfect for sealing, gasketing, and impact absorption. Selecting between vulcanized fiber and vulcanized rubber depends on whether your priority is rigidity and insulation versus flexibility and wear resistance.

Vulcanized fiber vs Vulcanized rubber Infographic

libmatt.com

libmatt.com