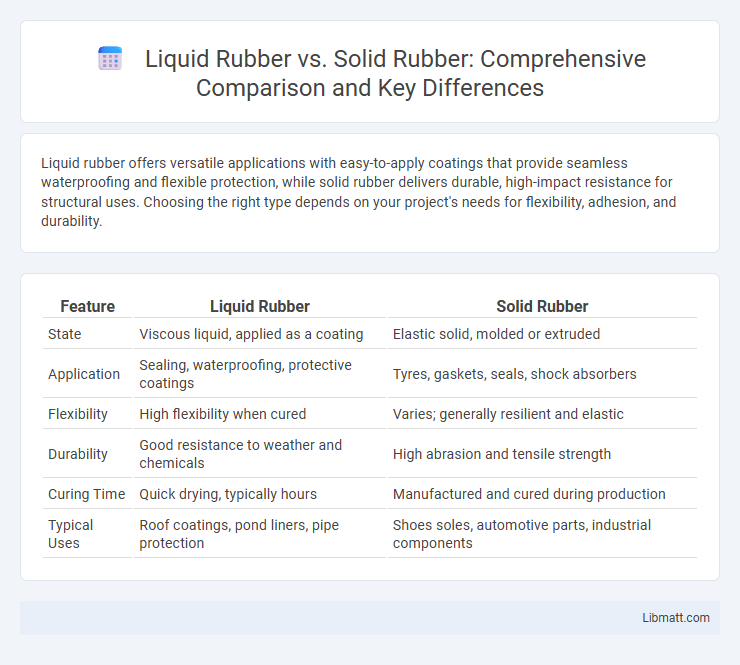

Liquid rubber offers versatile applications with easy-to-apply coatings that provide seamless waterproofing and flexible protection, while solid rubber delivers durable, high-impact resistance for structural uses. Choosing the right type depends on your project's needs for flexibility, adhesion, and durability.

Table of Comparison

| Feature | Liquid Rubber | Solid Rubber |

|---|---|---|

| State | Viscous liquid, applied as a coating | Elastic solid, molded or extruded |

| Application | Sealing, waterproofing, protective coatings | Tyres, gaskets, seals, shock absorbers |

| Flexibility | High flexibility when cured | Varies; generally resilient and elastic |

| Durability | Good resistance to weather and chemicals | High abrasion and tensile strength |

| Curing Time | Quick drying, typically hours | Manufactured and cured during production |

| Typical Uses | Roof coatings, pond liners, pipe protection | Shoes soles, automotive parts, industrial components |

Introduction to Liquid Rubber and Solid Rubber

Liquid rubber is a versatile, flexible coating made from synthetic polymers, ideal for waterproofing, sealing, and protecting surfaces with a seamless barrier. Solid rubber, derived from natural or synthetic sources, is a durable elastic material commonly used in tires, gaskets, and industrial products for its resilience and cushioning properties. Understanding the unique characteristics of liquid rubber versus solid rubber helps you select the optimal material for specific applications like coatings, repairs, or manufacturing components.

Composition and Chemical Structure

Liquid rubber typically consists of polymers dissolved or dispersed in solvents, featuring a flexible, amorphous molecular structure that allows it to flow and cure into a solid state. Solid rubber is composed of cross-linked polymer chains, such as natural rubber (cis-1,4-polyisoprene) or synthetic variants like styrene-butadiene rubber, providing a rigid, elastic network. The chemical structure of solid rubber is defined by extensive vulcanization, forming sulfur bridges that enhance durability and mechanical strength, unlike liquid rubber which remains uncured until applied and processed.

Manufacturing Processes

Liquid rubber is produced through polymerization of monomers into a viscous, flexible compound that cures upon exposure to air or heat, enabling seamless application on intricate surfaces. Solid rubber involves vulcanization, where raw rubber is heated with sulfur to enhance elasticity and durability, resulting in a dense, resilient material suitable for molding or extrusion. Understanding these manufacturing differences helps you select the appropriate rubber type for specific industrial or consumer applications.

Key Physical Properties

Liquid rubber exhibits superior flexibility and excellent adhesion due to its polymer chains in a viscous state, making it ideal for coatings and sealants. Solid rubber offers higher tensile strength and durability from its cross-linked network structure, providing robust resistance to abrasion and impact. Your choice between the two depends on whether elasticity or toughness is more critical for the application.

Application Areas and Industry Uses

Liquid rubber is extensively used for waterproof coatings, roof repairs, and flexible seals in construction and automotive industries due to its ease of application and seamless finish. Solid rubber finds applications in manufacturing tires, conveyor belts, and heavy-duty industrial gaskets because of its durability and structural integrity. Your choice depends on whether flexibility and coating or rigidity and mechanical strength are priorities for the specific industrial use.

Performance in Harsh Environments

Liquid rubber offers superior sealing and flexibility in harsh environments, effectively resisting water, chemicals, and UV damage, which helps maintain durability and elasticity over time. Solid rubber provides robust mechanical strength and abrasion resistance but can crack or degrade under extreme temperature fluctuations and prolonged exposure to harsh chemicals. Choosing between liquid and solid rubber depends on the specific environmental stresses, with liquid rubber favored for coatings and seals and solid rubber preferred for structural applications requiring toughness.

Installation and Ease of Use

Liquid rubber offers straightforward installation with its pourable and brushable application, easily conforming to irregular surfaces and reducing labor time compared to solid rubber sheets. Solid rubber requires precise cutting and fitting, often demanding professional tools and expertise to ensure proper alignment and adhesion. Your choice depends on whether you prioritize quick, seamless coating or durable, pre-formed material suited for structured installations.

Durability and Maintenance

Liquid rubber provides excellent durability through its flexible, seamless coating that resists cracking, UV damage, and water infiltration, reducing the need for frequent repairs. Solid rubber, while inherently tough and shock-absorbent, may develop cracks or wear over time due to environmental stress and requires periodic maintenance such as sealing or replacement. Maintenance of liquid rubber surfaces typically involves simple cleaning and occasional recoating, whereas solid rubber demands more intensive care to preserve its structural integrity.

Cost Comparison and Economic Considerations

Liquid rubber generally offers a lower initial cost due to easier application and reduced labor expenses, making it an economical choice for large surface areas or complex shapes. Solid rubber requires higher upfront investment because of material costs and manufacturing processes, but it often provides greater durability and longevity, potentially lowering replacement frequency and long-term expenses. Your decision should weigh immediate budget constraints against projected maintenance and lifespan to optimize economic value.

Choosing the Right Rubber: Factors to Consider

Choosing the right rubber between liquid rubber and solid rubber depends on factors such as application flexibility, environmental resistance, and durability requirements. Liquid rubber offers superior sealing and waterproofing capabilities with easy application on complex surfaces, making it ideal for coatings and flexible membranes. Solid rubber provides better structural strength and impact resistance, suitable for products needing rigidity and long-lasting wear under heavy mechanical stress.

Liquid Rubber vs Solid Rubber Infographic

libmatt.com

libmatt.com