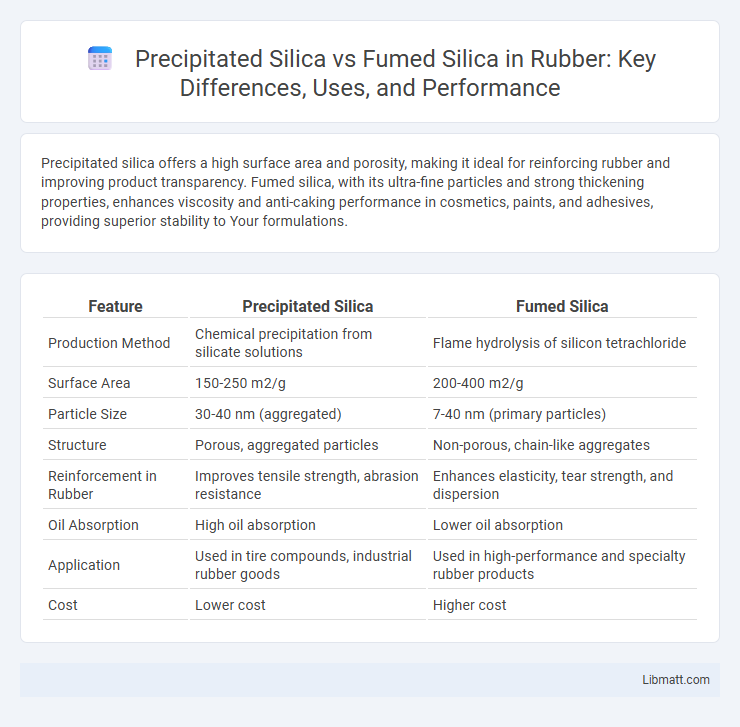

Precipitated silica offers a high surface area and porosity, making it ideal for reinforcing rubber and improving product transparency. Fumed silica, with its ultra-fine particles and strong thickening properties, enhances viscosity and anti-caking performance in cosmetics, paints, and adhesives, providing superior stability to Your formulations.

Table of Comparison

| Feature | Precipitated Silica | Fumed Silica |

|---|---|---|

| Production Method | Chemical precipitation from silicate solutions | Flame hydrolysis of silicon tetrachloride |

| Surface Area | 150-250 m2/g | 200-400 m2/g |

| Particle Size | 30-40 nm (aggregated) | 7-40 nm (primary particles) |

| Structure | Porous, aggregated particles | Non-porous, chain-like aggregates |

| Reinforcement in Rubber | Improves tensile strength, abrasion resistance | Enhances elasticity, tear strength, and dispersion |

| Oil Absorption | High oil absorption | Lower oil absorption |

| Application | Used in tire compounds, industrial rubber goods | Used in high-performance and specialty rubber products |

| Cost | Lower cost | Higher cost |

Introduction to Silica: Precipitated vs Fumed

Precipitated silica is produced by the controlled precipitation of sodium silicate in acidic conditions, resulting in a fine, porous powder commonly used as a reinforcing agent and thickener in various industries. Fumed silica, also known as pyrogenic silica, is created through the flame hydrolysis of silicon tetrachloride, yielding ultra-fine, amorphous particles with high surface area and thickening properties ideal for adhesives, coatings, and sealants. Both types exhibit distinct particle morphology and surface chemistry, influencing their performance in applications like rubber reinforcement, cosmetics, and filtration.

Understanding Precipitated Silica

Precipitated silica is a fine, white, amorphous substance produced by the controlled neutralization of sodium silicate with sulfuric acid, resulting in a hydrated silica gel that is subsequently filtered, washed, and dried. Its porous structure and high surface area make it ideal for use as a reinforcing filler in rubber, a thickening agent in adhesives, and an anti-caking agent in food processing. Compared to fumed silica, precipitated silica offers better dispersion in liquid systems and is more cost-effective, making it a preferred choice for various industrial applications.

Exploring Fumed Silica

Fumed silica, also known as pyrogenic silica, is produced through the flame hydrolysis of silicon tetrachloride, resulting in ultra-fine, highly pure particles with a high surface area. It offers superior thickening, reinforcing, and anti-caking properties in applications like coatings, adhesives, and cosmetics due to its unique chain-like molecular structure. You benefit from enhanced flow control and improved mechanical strength when choosing fumed silica over precipitated silica in specialized formulations.

Manufacturing Processes: Key Differences

Precipitated silica is produced through a chemical reaction between sodium silicate and sulfuric acid, resulting in a wet gel that is washed, filtered, and dried. Fumed silica, on the other hand, is manufactured via flame hydrolysis of silicon tetrachloride in a high-temperature hydrogen-oxygen flame, creating ultra-fine, high-purity particles. Understanding these manufacturing processes highlights the differences in particle structure, purity, and surface area, which directly impact their applications and performance in your formulations.

Physical and Chemical Properties Comparison

Precipitated silica features larger particle sizes and a more irregular shape, resulting in lower surface area and porosity compared to the highly dispersed, nano-sized particles of fumed silica that offer a significantly higher surface area exceeding 200 m2/g. Chemically, both silicas are primarily composed of silicon dioxide (SiO2), but fumed silica's surface contains reactive silanol groups that enhance its ability to form hydrogen bonds, unlike precipitated silica, which has fewer surface hydroxyl groups. These differences influence their physical behavior in applications, with fumed silica providing superior thickening, reinforcing, and anti-caking properties due to its fine particle distribution and higher surface activity.

Applications of Precipitated Silica

Precipitated silica is widely used as a reinforcing filler in tire manufacturing to enhance wet traction and fuel efficiency. It serves as a thickening agent and anti-caking component in food products, pharmaceuticals, and cosmetics due to its high purity and controlled particle size. Industrial applications also include detergents, paints, and coatings where it improves abrasiveness and opacity.

Applications of Fumed Silica

Fumed silica is widely used as a rheology modifier and thickening agent in industries such as paints, coatings, adhesives, and sealants due to its ability to enhance viscosity and prevent sagging. Its high surface area and hydrophobic properties make it valuable in silicone elastomers, personal care products, and pharmaceuticals for improving texture and stability. In electronics, fumed silica acts as a reinforcing filler, enhancing mechanical strength and insulation properties in advanced composites and conductive materials.

Performance Advantages and Limitations

Precipitated silica offers excellent dispersibility and high purity, making it ideal for applications requiring strong reinforcement and low abrasion, while fumed silica provides superior thixotropy and surface area for enhanced viscosity control and stability. Precipitated silica's larger particle size leads to lower surface energy but may limit its effectiveness in ultra-fine formulations; fumed silica's nanoscale structure boosts performance in coatings and adhesives but comes at a higher cost and potential handling challenges. Your choice between these silicas depends on balancing performance factors like rheology, mechanical strength, and processing conditions.

Cost and Environmental Considerations

Precipitated silica generally costs less than fumed silica due to lower energy consumption during production, making it a more economical choice for large-scale industrial applications. Fumed silica manufacturing requires high-temperature flame hydrolysis, resulting in higher energy use and increased carbon footprint, raising environmental concerns. The environmentally friendlier profile of precipitated silica enhances its appeal in green manufacturing processes where sustainability and cost-efficiency are critical.

Choosing the Right Silica for Your Needs

Precipitated silica offers larger particle sizes and higher moisture absorption, making it ideal for applications like rubber reinforcement and toothpaste formulations, whereas fumed silica, with its ultra-fine particles and high surface area, excels in thickening, anti-caking, and improving flow in coatings and adhesives. Selecting the right silica depends on specific industry requirements such as dispersibility, surface treatment compatibility, and the desired rheological properties of the final product. Understanding these distinctions ensures optimized performance and cost-efficiency in manufacturing and product development.

Precipitated vs Fumed Silica Infographic

libmatt.com

libmatt.com