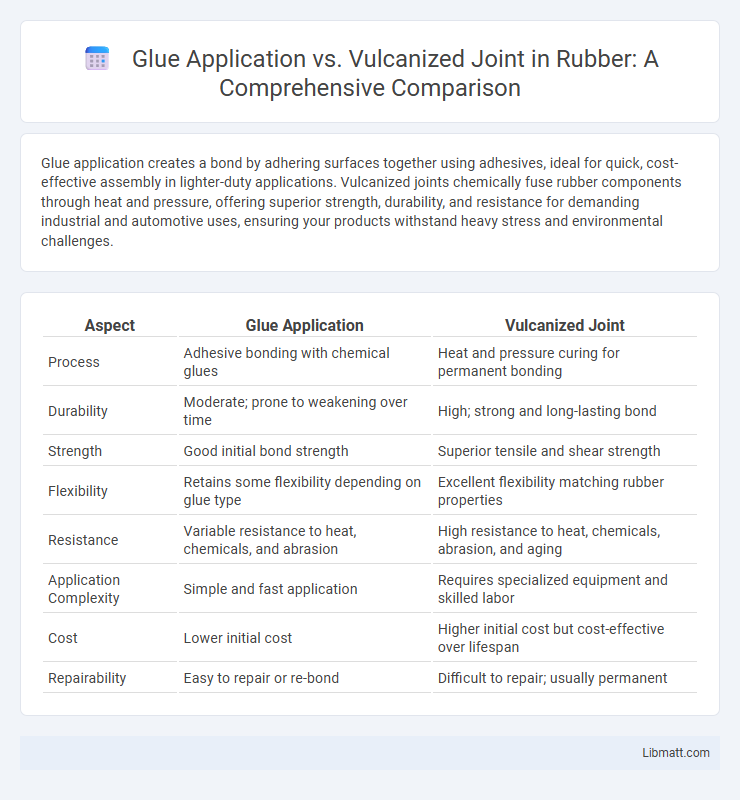

Glue application creates a bond by adhering surfaces together using adhesives, ideal for quick, cost-effective assembly in lighter-duty applications. Vulcanized joints chemically fuse rubber components through heat and pressure, offering superior strength, durability, and resistance for demanding industrial and automotive uses, ensuring your products withstand heavy stress and environmental challenges.

Table of Comparison

| Aspect | Glue Application | Vulcanized Joint |

|---|---|---|

| Process | Adhesive bonding with chemical glues | Heat and pressure curing for permanent bonding |

| Durability | Moderate; prone to weakening over time | High; strong and long-lasting bond |

| Strength | Good initial bond strength | Superior tensile and shear strength |

| Flexibility | Retains some flexibility depending on glue type | Excellent flexibility matching rubber properties |

| Resistance | Variable resistance to heat, chemicals, and abrasion | High resistance to heat, chemicals, abrasion, and aging |

| Application Complexity | Simple and fast application | Requires specialized equipment and skilled labor |

| Cost | Lower initial cost | Higher initial cost but cost-effective over lifespan |

| Repairability | Easy to repair or re-bond | Difficult to repair; usually permanent |

Introduction to Conveyor Belt Jointing Methods

Conveyor belt jointing methods are crucial for maintaining belt integrity and operational efficiency, with glue application and vulcanized joints being the primary techniques used. Glue application offers a quick and cost-effective solution for light to medium-duty belts, providing ease of repair and minimal downtime. Vulcanized joints, involving heat and pressure to fuse belt ends, deliver superior strength and durability, making them ideal for heavy-duty conveyor systems where long-term reliability is essential.

Overview of Glue Application Technique

The glue application technique involves applying an adhesive layer between surfaces to bond materials, commonly used in industries requiring flexible, lightweight, and moisture-resistant joints. This method allows for precise control over adhesive thickness and curing time, enhancing bond strength and durability in applications like automotive and aerospace. Unlike vulcanized joints, glue applications do not require heat or pressure vulcanization processes, making them suitable for temperature-sensitive materials.

Overview of Vulcanized Joint Process

The vulcanized joint process involves bonding rubber materials by applying heat, pressure, and sulfur or other curing agents to create a chemically cross-linked, durable connection. This method enhances the joint's strength, elasticity, and resistance to environmental factors compared to glued joints. Your products benefit from increased longevity and performance due to the vulcanization's molecular integration of materials.

Key Differences Between Glue Application and Vulcanized Joints

Glue application involves bonding materials using adhesive substances that cure at room temperature, offering a quick and flexible joint solution suitable for various surfaces. Vulcanized joints are formed through a chemical process that cures rubber under heat and pressure, creating a stronger and more durable bond with enhanced resistance to environmental factors. The primary differences lie in the mechanical strength, heat resistance, and longevity, with vulcanized joints outperforming glued joints in demanding industrial applications.

Strength and Durability Comparison

Glue applications typically offer moderate strength and durability suitable for light to medium loads, but their bond may weaken under prolonged exposure to moisture or high temperatures. Vulcanized joints, created through a chemical bonding process involving heat and pressure, provide superior strength and long-lasting durability, making them ideal for heavy-duty or high-stress environments. Your choice between these methods should consider the specific demands of the application, as vulcanized joints generally outperform glued bonds in maintaining integrity over time.

Installation Time and Complexity

Glue applications typically offer quicker installation times and simpler procedures compared to vulcanized joints, which require specialized equipment and longer curing periods. Vulcanized joints involve a chemical bonding process under heat and pressure, leading to more complex setup and skill requirements. This complexity often results in extended downtime, whereas glue applications allow for faster project completion and reduced labor intensity.

Cost Analysis: Glue vs Vulcanization

Glue application typically incurs lower initial costs due to simpler equipment and faster curing times, making it ideal for small-scale or low-budget projects. Vulcanized joints, while more expensive upfront because of specialized machinery and longer processing times, offer superior durability and long-term cost savings in high-stress or heavy-duty applications. Over the lifecycle, vulcanization reduces maintenance expenses and joint failures, making it more cost-effective for industrial use despite the higher initial investment.

Suitability for Various Conveyor Belt Materials

Glue applications offer strong adhesion ideal for lightweight conveyor belts made from materials such as fabric, PVC, and PU, providing flexibility and ease of installation. Vulcanized joints are highly suitable for heavy-duty conveyor belts made from rubber and composite materials, delivering superior strength, durability, and resistance to wear and tear under high tension. Selecting the appropriate joint type depends on the conveyor belt material, operational demands, and required joint longevity.

Maintenance and Repair Considerations

Glue applications typically allow for easier maintenance and repair, as the adhesive bond can be softened or removed with solvents, enabling quick disassembly or re-bonding. Vulcanized joints offer superior durability and resistance, but repairs often require specialized equipment and re-heating processes, making on-site fixes more complex and time-consuming. Your choice depends on whether you prioritize straightforward repairs or long-lasting, high-strength connections.

Choosing the Best Joint Method for Your Operation

Selecting the best joint method for your operation depends on factors such as material type, load requirements, and environmental exposure. Glue applications provide a quick, cost-effective bond ideal for lightweight, non-structural assemblies with moderate stress levels. Vulcanized joints offer superior durability and resistance to heat, chemicals, and mechanical fatigue, making them optimal for heavy-duty, high-performance industrial uses.

Glue Application vs Vulcanized Joint Infographic

libmatt.com

libmatt.com