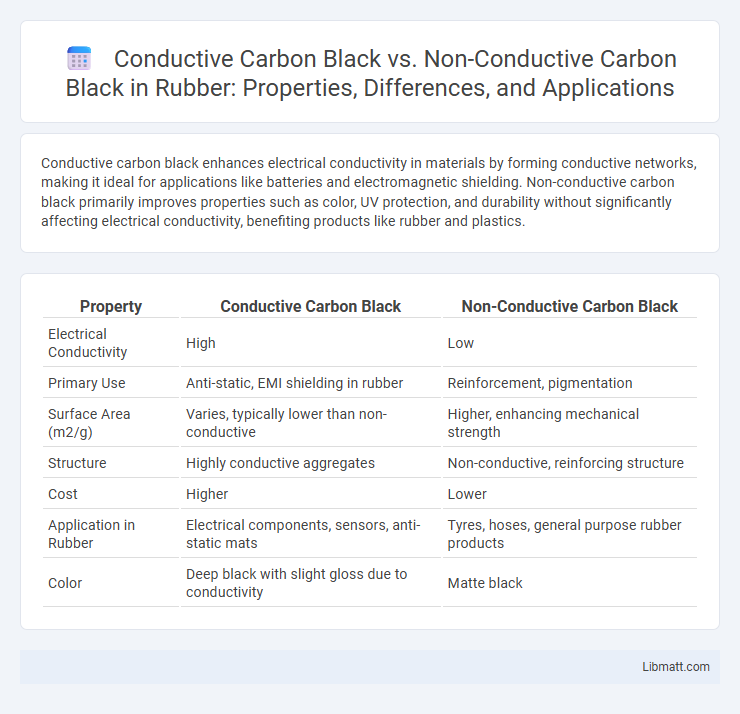

Conductive carbon black enhances electrical conductivity in materials by forming conductive networks, making it ideal for applications like batteries and electromagnetic shielding. Non-conductive carbon black primarily improves properties such as color, UV protection, and durability without significantly affecting electrical conductivity, benefiting products like rubber and plastics.

Table of Comparison

| Property | Conductive Carbon Black | Non-Conductive Carbon Black |

|---|---|---|

| Electrical Conductivity | High | Low |

| Primary Use | Anti-static, EMI shielding in rubber | Reinforcement, pigmentation |

| Surface Area (m2/g) | Varies, typically lower than non-conductive | Higher, enhancing mechanical strength |

| Structure | Highly conductive aggregates | Non-conductive, reinforcing structure |

| Cost | Higher | Lower |

| Application in Rubber | Electrical components, sensors, anti-static mats | Tyres, hoses, general purpose rubber products |

| Color | Deep black with slight gloss due to conductivity | Matte black |

Introduction to Carbon Black

Carbon black is a fine carbon powder produced by the incomplete combustion of heavy petroleum products, widely used as a reinforcing filler in rubber and as a pigment in plastics and inks. Conductive carbon black is specially processed to enhance electrical conductivity, making it essential in applications like batteries, conductive polymers, and antistatic materials. You should choose non-conductive carbon black when electrical insulation is required, as it primarily improves physical properties without affecting conductivity.

Overview of Conductive Carbon Black

Conductive carbon black is a specialized form of carbon black characterized by its enhanced electrical conductivity due to its unique particle structure and high surface area. It is widely used in applications requiring static dissipation, electromagnetic interference (EMI) shielding, and improved electrical performance in polymers and coatings. Compared to non-conductive carbon black, conductive carbon black undergoes specific manufacturing processes to optimize its conductive pathways, making it essential in industries such as automotive, electronics, and energy storage.

Key Properties of Non-Conductive Carbon Black

Non-conductive carbon black exhibits low electrical conductivity due to its smaller particle size and lower structure compared to conductive variants, making it ideal for applications requiring insulation. It offers excellent reinforcing properties in rubber compounds, enhancing tensile strength, abrasion resistance, and durability without compromising electrical isolation. This type of carbon black is commonly used in tires, seals, and gaskets where mechanical performance is critical but electrical conductivity must be minimized.

Production Processes Compared

Conductive carbon black is produced through a controlled furnace process that generates particles with high structure and surface area to enhance electrical conductivity. Non-conductive carbon black typically undergoes a channel or gas black process, resulting in larger particle sizes and lower surface areas, which reduce conductivity. Your choice between the two relies heavily on the production method because it directly influences the material's electrical properties and application suitability.

Electrical Conductivity Differences

Conductive carbon black possesses a high degree of electrical conductivity due to its structured, graphitic carbon particles that form conductive networks, making it ideal for applications requiring efficient electron flow. Non-conductive carbon black, in contrast, has a more amorphous structure with limited electron pathways, resulting in poor electrical conductivity suited for pigmentation and reinforcement rather than electrical applications. Understanding these electrical conductivity differences helps you choose the appropriate carbon black type for optimized performance in electronics, coatings, or composite materials.

Common Applications of Both Types

Conductive carbon black is widely utilized in applications requiring electrical conductivity, such as in batteries, conductive coatings, and antistatic materials, enhancing performance and safety. Non-conductive carbon black finds its primary use in reinforcing rubber products, plastics, and inks, improving durability and color quality without affecting electrical properties. Understanding the distinct applications of these carbon black types helps you select the right material for specific industrial or commercial needs.

Performance in Polymer Composites

Conductive carbon black significantly enhances the electrical conductivity of polymer composites, making it ideal for antistatic and electromagnetic shielding applications. Non-conductive carbon black primarily improves mechanical properties such as tensile strength and UV resistance without altering electrical characteristics. Your choice between these types depends on whether electrical performance or structural reinforcement is the priority in your polymer composite design.

Cost and Availability Comparison

Conductive carbon black typically costs more than non-conductive carbon black due to its specialized manufacturing processes and enhanced electrical properties. Non-conductive carbon black is widely available and produced in larger quantities, making it a more cost-effective option for applications requiring pigmentation or reinforcement without conductivity. Your choice depends on balancing budget constraints with the specific electrical performance needed in your project.

Environmental and Safety Considerations

Conductive Carbon Black is often produced using processes that emit fewer volatile organic compounds (VOCs) compared to Non-Conductive Carbon Black, making it a more environmentally friendly choice in industrial applications. The handling of Conductive Carbon Black requires strict safety measures due to its fine particle size and potential for respiratory hazards, whereas Non-Conductive Carbon Black typically poses lower dust explosion risks but still necessitates appropriate protective equipment. Proper disposal and recycling methods for Conductive Carbon Black help minimize environmental impact, while Non-Conductive Carbon Black's inert nature reduces its ecological footprint but demands vigilance to prevent air quality contamination.

Selecting the Right Carbon Black for Industrial Use

Selecting the right carbon black for industrial use depends on its electrical conductivity and application requirements. Conductive carbon black offers enhanced electron flow, making it ideal for antistatic coatings, conductive polymers, and battery electrodes. Non-conductive carbon black excels in pigmentation, UV protection, and filler reinforcement, ensuring your products achieve desired durability, color intensity, and mechanical strength.

Conductive Carbon Black vs Non-Conductive Carbon Black Infographic

libmatt.com

libmatt.com