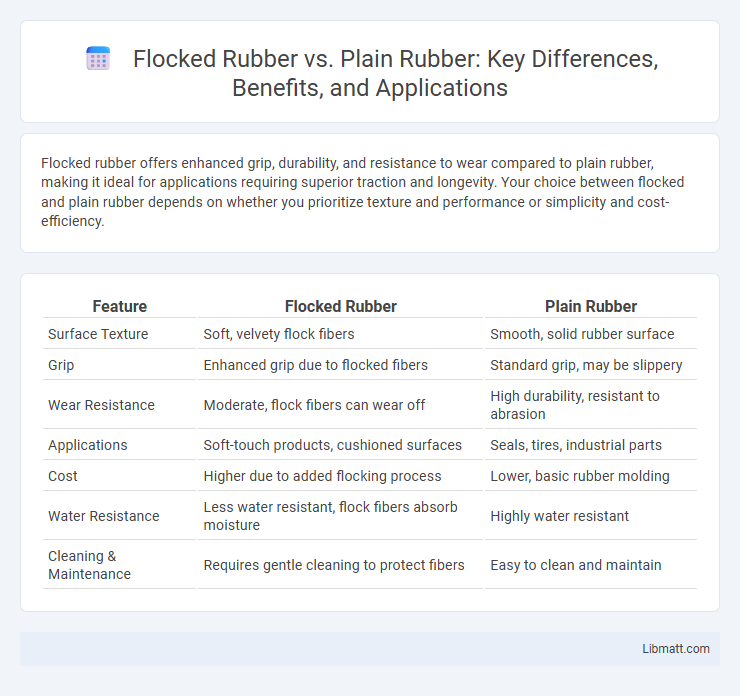

Flocked rubber offers enhanced grip, durability, and resistance to wear compared to plain rubber, making it ideal for applications requiring superior traction and longevity. Your choice between flocked and plain rubber depends on whether you prioritize texture and performance or simplicity and cost-efficiency.

Table of Comparison

| Feature | Flocked Rubber | Plain Rubber |

|---|---|---|

| Surface Texture | Soft, velvety flock fibers | Smooth, solid rubber surface |

| Grip | Enhanced grip due to flocked fibers | Standard grip, may be slippery |

| Wear Resistance | Moderate, flock fibers can wear off | High durability, resistant to abrasion |

| Applications | Soft-touch products, cushioned surfaces | Seals, tires, industrial parts |

| Cost | Higher due to added flocking process | Lower, basic rubber molding |

| Water Resistance | Less water resistant, flock fibers absorb moisture | Highly water resistant |

| Cleaning & Maintenance | Requires gentle cleaning to protect fibers | Easy to clean and maintain |

Introduction to Flocked and Plain Rubber

Flocked rubber features a surface coated with tiny fibers, enhancing grip and reducing slippage compared to plain rubber, which has a smooth, uniform surface. The flocking process improves tactile sensation and moisture absorption, making flocked rubber ideal for applications requiring enhanced friction or comfort. Plain rubber offers durability and resistance to wear, commonly used in industrial and commercial settings where a consistent, non-porous material is essential.

What is Flocked Rubber?

Flocked rubber features a surface coated with tiny synthetic fibers, creating a soft, textured finish that enhances grip and comfort compared to plain rubber. Unlike plain rubber, which has a smooth and often slippery surface, flocked rubber offers improved tactile feedback and durability, making it ideal for applications requiring non-slip properties and aesthetic appeal. Your choice between flocked and plain rubber depends on the need for enhanced grip, wear resistance, or a specific texture in products like handles, seals, or gaskets.

What is Plain Rubber?

Plain rubber is a smooth, non-textured material valued for its flexibility and durability in industrial and consumer applications. Unlike flocked rubber, which has a surface coating of fine fibers for enhanced grip, plain rubber provides a uniform surface ideal for sealing, cushioning, and insulating purposes. Your choice of plain rubber ensures consistent performance in environments requiring minimal friction and easy cleaning.

Composition and Manufacturing Differences

Flocked rubber features a surface coated with tiny nylon or nylon-like fibers that create a velvet-like texture, achieved through an electrostatic process during manufacturing, while plain rubber is a solid, smooth material without any fiber coating. The composition of flocked rubber combines a standard rubber base with adhesive and flock fibers, enhancing grip and reducing slippage compared to plain rubber, which consists solely of natural or synthetic rubber compounds. Your choice between flocked and plain rubber depends on the application requirements for texture, durability, and grip performance.

Key Performance Characteristics

Flocked rubber offers superior grip and abrasion resistance compared to plain rubber, making it ideal for applications requiring enhanced traction and durability. Plain rubber provides greater flexibility and is more cost-effective, but it tends to wear out faster under friction-intensive conditions. The choice between flocked and plain rubber hinges on balancing performance needs like wear resistance, grip, and elasticity for specific industrial or consumer uses.

Applications of Flocked Rubber

Flocked rubber is widely used in applications requiring enhanced grip, cushioning, and noise reduction, such as automotive seals, gaskets, and vibration dampening components. Its textured surface improves friction and prevents slipping, making it ideal for door and window seals as well as protective padding. Industries like automotive, electronics, and consumer goods benefit from flocked rubber for its durability and superior tactile properties compared to plain rubber.

Applications of Plain Rubber

Plain rubber is widely used in automotive seals, gaskets, and hoses due to its excellent elasticity and resistance to wear. Its smooth surface provides effective airtight and watertight sealing in industrial equipment, making it ideal for manufacturing O-rings and diaphragms. Furthermore, plain rubber's chemical inertness allows it to perform reliably in various medical devices and consumer goods.

Durability and Longevity Comparison

Flocked rubber offers enhanced durability compared to plain rubber due to its textured surface, which resists wear and tear more effectively under friction. The flocking process adds a protective layer that maintains the rubber's integrity over prolonged use, resulting in extended longevity for applications such as seals and grips. In contrast, plain rubber tends to degrade faster when exposed to abrasion and environmental factors, reducing its lifespan in high-stress conditions.

Cost and Economic Considerations

Flocked rubber incurs higher initial costs due to the added flocking process involving adhesive and fiber application, which enhances grip and tactile comfort. Plain rubber is generally more cost-effective, offering basic durability and performance without additional manufacturing steps. For large-scale production or budget-sensitive applications, plain rubber often provides better economic value despite its simpler functionality.

Choosing Between Flocked and Plain Rubber

Choosing between flocked rubber and plain rubber hinges on the desired tactile feel and application requirements; flocked rubber offers a textured surface that enhances grip and reduces slippage, making it ideal for handles and sports equipment. Plain rubber provides a smooth, uniform finish prized for its ease of cleaning and consistent contact, suitable for seals and flexible tubing. Consider factors like durability, cost, and environmental conditions to determine the optimal rubber type for specific industrial or consumer uses.

Flocked rubber vs Plain rubber Infographic

libmatt.com

libmatt.com