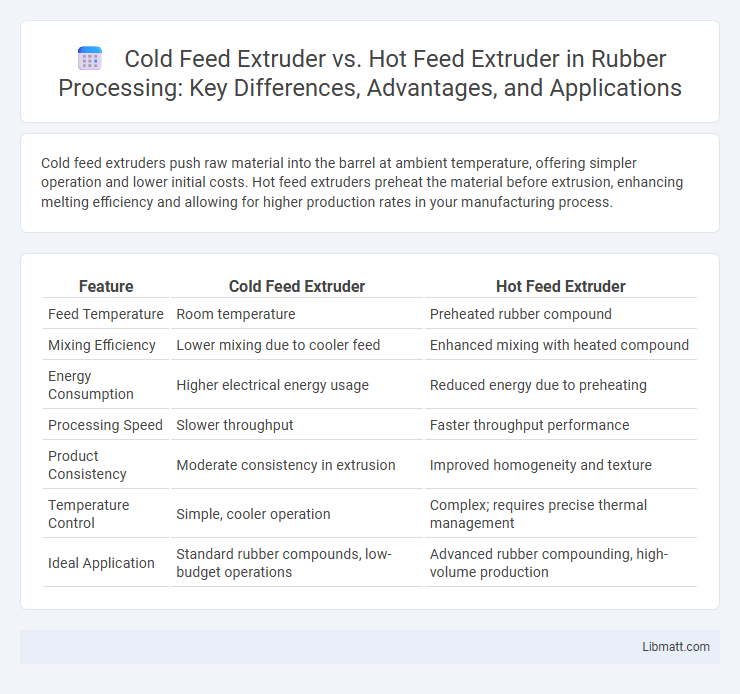

Cold feed extruders push raw material into the barrel at ambient temperature, offering simpler operation and lower initial costs. Hot feed extruders preheat the material before extrusion, enhancing melting efficiency and allowing for higher production rates in your manufacturing process.

Table of Comparison

| Feature | Cold Feed Extruder | Hot Feed Extruder |

|---|---|---|

| Feed Temperature | Room temperature | Preheated rubber compound |

| Mixing Efficiency | Lower mixing due to cooler feed | Enhanced mixing with heated compound |

| Energy Consumption | Higher electrical energy usage | Reduced energy due to preheating |

| Processing Speed | Slower throughput | Faster throughput performance |

| Product Consistency | Moderate consistency in extrusion | Improved homogeneity and texture |

| Temperature Control | Simple, cooler operation | Complex; requires precise thermal management |

| Ideal Application | Standard rubber compounds, low-budget operations | Advanced rubber compounding, high-volume production |

Introduction to Cold Feed and Hot Feed Extruders

Cold feed extruders use pellets or granules fed directly into the barrel, melting them through friction and heat generated by the screw, ideal for materials sensitive to heat. Hot feed extruders introduce pre-melted or heated materials into the barrel, allowing for more precise control over melting and flow, commonly used for complex formulations. Your choice between cold feed and hot feed extruders depends on material properties and production requirements, impacting efficiency and product quality.

Basic Working Principles

Cold Feed Extruders operate by mechanically pushing solid raw materials into the barrel where heat and pressure transform them into a homogeneous melt. Hot Feed Extruders, however, introduce preheated or melted materials directly into the barrel, reducing mechanical energy requirements and improving material flow consistency. The fundamental difference lies in the initial material state, influencing energy consumption, processing speed, and product uniformity.

Key Differences Between Cold Feed and Hot Feed Extruders

Cold feed extruders introduce raw material at ambient temperature, relying on external heating in the barrel to melt the material, while hot feed extruders begin with pre-heated or molten material, enabling faster processing and better control over melt consistency. The temperature control precision, feed mechanism, and energy efficiency significantly differ, with cold feed extruders being more versatile for solid pellets and hot feed extruders suitable for viscous or liquid inputs. Understanding these distinctions allows you to select the optimal extruder type for your specific application, balancing processing speed, material properties, and energy consumption.

Materials Suitable for Each Extruder Type

Cold feed extruders are ideal for processing thermoplastics such as polyethylene, polypropylene, and polyvinyl chloride, where material temperature control is critical to maintain physical properties. Hot feed extruders suit materials with higher melting points or heat sensitivity, including engineering plastics like polycarbonate, nylon, and acetal, allowing for efficient melting and homogenization. Selection depends on material viscosity, thermal sensitivity, and desired product quality in extrusion manufacturing.

Energy Efficiency Comparison

Cold feed extruders typically consume less energy due to their lower operating temperatures, reducing the need for extensive heating elements and enabling more efficient power use. Hot feed extruders require higher thermal input to maintain elevated temperatures for material melting, leading to increased energy consumption and operational costs. Choosing between the two depends on the specific application requirements, balancing energy efficiency with material processing needs.

Process Control and Automation

Cold Feed Extruders offer greater precision in process control by allowing consistent material feeding with minimal temperature influence, resulting in stable output quality ideal for automation in industries requiring fine-tuned operations. Hot Feed Extruders integrate temperature regulation within the feed system, enabling rapid process adjustments but requiring advanced control algorithms to manage thermal fluctuations for automated systems. Your choice impacts the complexity of automation implementation, where cold feed systems favor consistency and hot feed systems provide dynamic adaptability to production variations.

Cost Implications and Initial Investment

Cold feed extruders typically require a lower initial investment compared to hot feed extruders due to their simpler design and reduced heating components. However, operating costs may vary as hot feed extruders often offer greater production efficiency and material flexibility, potentially lowering long-term expenses. Your choice between the two should consider both upfront capital and ongoing operational costs to optimize budget and performance.

Applications in Industrial Manufacturing

Cold feed extruders are primarily used in applications requiring precise control over material temperature, such as in the production of pharmaceutical pellets and food products, where thermal degradation must be minimized. Hot feed extruders excel in manufacturing processes involving polymers and rubber compounds, enabling continuous melting and shaping for high-volume industrial applications like plastic tubing and automotive parts. Your choice between these extruders depends on the specific material properties and thermal requirements of your industrial manufacturing process.

Advantages and Disadvantages Analysis

Cold feed extruders offer precise control over material feeding and reduced thermal degradation, making them ideal for temperature-sensitive polymers, but they may face challenges with inconsistent output rates and higher wear due to direct material contact. Hot feed extruders provide higher throughput and better mixing by preheating the material before feeding, increasing efficiency for thermoplastics with uniform melting points; however, they risk material degradation and require more complex temperature management systems. Understanding these trade-offs helps you select the appropriate extruder type based on your processing goals and material characteristics.

Choosing the Right Extruder for Your Needs

Choosing the right extruder depends on your material properties and production goals, with cold feed extruders ideal for processing thermoplastics at lower temperatures, ensuring material integrity and reducing thermal degradation. Hot feed extruders are better suited for high-viscosity polymers, offering precise temperature control and consistent melt quality for applications requiring uniformity and strength. Evaluating the specific demands of your manufacturing process, such as throughput rate and product specifications, will guide the optimal extruder selection.

Cold Feed Extruder vs Hot Feed Extruder Infographic

libmatt.com

libmatt.com