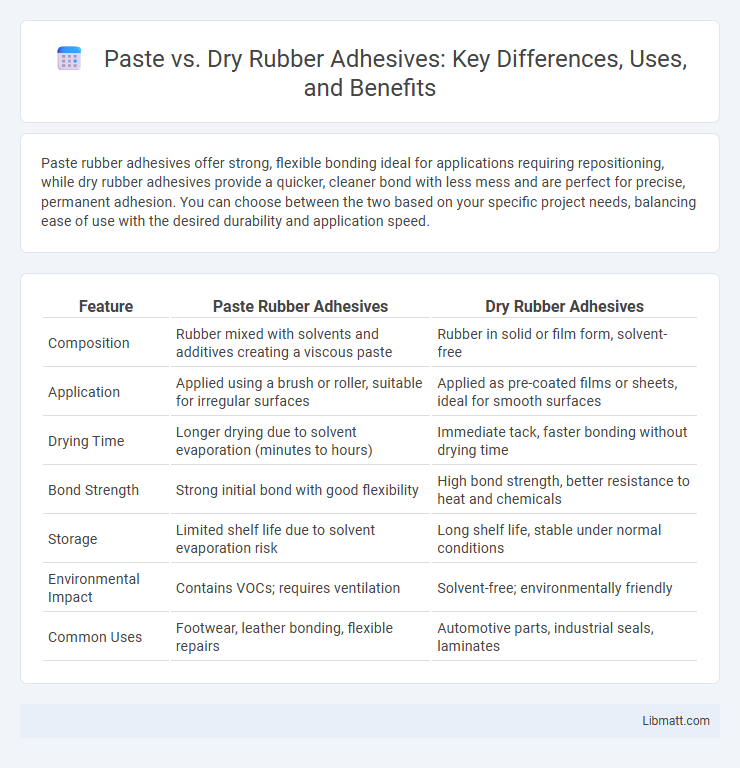

Paste rubber adhesives offer strong, flexible bonding ideal for applications requiring repositioning, while dry rubber adhesives provide a quicker, cleaner bond with less mess and are perfect for precise, permanent adhesion. You can choose between the two based on your specific project needs, balancing ease of use with the desired durability and application speed.

Table of Comparison

| Feature | Paste Rubber Adhesives | Dry Rubber Adhesives |

|---|---|---|

| Composition | Rubber mixed with solvents and additives creating a viscous paste | Rubber in solid or film form, solvent-free |

| Application | Applied using a brush or roller, suitable for irregular surfaces | Applied as pre-coated films or sheets, ideal for smooth surfaces |

| Drying Time | Longer drying due to solvent evaporation (minutes to hours) | Immediate tack, faster bonding without drying time |

| Bond Strength | Strong initial bond with good flexibility | High bond strength, better resistance to heat and chemicals |

| Storage | Limited shelf life due to solvent evaporation risk | Long shelf life, stable under normal conditions |

| Environmental Impact | Contains VOCs; requires ventilation | Solvent-free; environmentally friendly |

| Common Uses | Footwear, leather bonding, flexible repairs | Automotive parts, industrial seals, laminates |

Introduction to Paste and Dry Rubber Adhesives

Paste adhesives consist of a viscous, semi-liquid substance that provides strong initial tack and is ideal for bonding porous materials like paper and fabric. Dry rubber adhesives, often supplied as pre-applied, non-tacky films or sheets, become adhesive only after activation through heat or pressure, making them suitable for precise assembly and clean application. Both types offer unique bonding properties tailored to specific industrial and manufacturing processes, with paste adhesives excelling in flexibility and repositionability, while dry rubber adhesives emphasize durability and controlled application.

Definitions and Basic Composition

Paste adhesives consist of a viscous, water-based polymer mixture designed for flexible bonding, typically including starch or synthetic resins to enhance adhesion and moisture resistance. Dry rubber adhesives contain solid rubber particles dispersed in a solvent or water, forming a tacky, pressure-sensitive layer upon drying that provides strong, elastic bonding properties. Your choice between paste and dry rubber adhesives depends on the application requirements such as flexibility, drying time, and surface compatibility.

Key Differences Between Paste and Dry Rubber Adhesives

Paste rubber adhesives typically contain a solvent or water-based medium that keeps the adhesive in a viscous, spreadable form, allowing for easy application and repositioning. Dry rubber adhesives are solid or semi-solid, activating through heat or pressure to form strong, immediate bonds without the need for evaporation or drying time. The key differences lie in their application methods, drying or curing processes, and suitability for various substrates and industrial uses.

Common Applications in Various Industries

Paste adhesives are widely used in industries such as woodworking, packaging, and bookbinding due to their strong initial tack and ease of repositioning. Dry rubber adhesives are favored in the automotive and electronics sectors for their durability, resistance to heat, and ability to maintain bonds under stress. Both types serve crucial roles in manufacturing processes that require flexible yet robust bonding solutions.

Advantages of Paste Rubber Adhesives

Paste rubber adhesives offer superior bonding strength and flexibility, making them ideal for applications requiring durable and elastic joins. Their thick consistency allows for precise application on vertical or uneven surfaces, reducing the risk of drips and wastage. These adhesives also provide enhanced resistance to moisture and chemicals compared to dry rubber adhesives, ensuring longer-lasting performance in harsh environments.

Benefits of Dry Rubber Adhesives

Dry rubber adhesives offer superior bonding strength and excellent resistance to moisture, making them ideal for applications requiring durable and long-lasting adhesion. They provide faster drying times compared to paste adhesives, reducing production cycles and improving efficiency. Their clean, non-messy application enhances workplace safety and minimizes material waste, supporting cost-effective and sustainable manufacturing processes.

Application Techniques and Best Practices

Paste adhesives require precise spreading with a notched trowel or spatula to ensure even coverage and avoid air bubbles, making them ideal for heavier or uneven surfaces. Dry rubber adhesives are applied as thin films or sprayed coatings, allowing for quick bonding and repositioning before final set, best suited for lightweight materials and flexible substrates. Your choice between paste and dry rubber adhesives should consider the substrate type and desired working time to optimize adhesion strength and durability.

Performance and Durability Comparison

Paste adhesives offer strong initial tack and flexibility, making them ideal for applications requiring repositioning and gap-filling; however, they may be susceptible to drying out and reduced long-term adhesion under harsh environmental conditions. Dry rubber adhesives provide superior durability and resistance to moisture, heat, and chemicals, maintaining high tensile strength over extended periods, which makes them suitable for heavy-duty bonding and industrial use. Performance-wise, paste adhesives excel in short-term flexibility, while dry rubber adhesives deliver enhanced permanence and reliability in demanding environments.

Environmental and Safety Considerations

Paste adhesives often contain volatile organic compounds (VOCs) that emit harmful fumes, posing health risks and requiring adequate ventilation during application. Dry rubber adhesives typically have lower VOC content, reducing environmental impact and improving indoor air quality. Proper handling and disposal of both adhesive types are critical to minimize ecological harm and ensure workplace safety.

Choosing the Right Adhesive: Paste vs Dry Rubber

Choosing the right adhesive between paste and dry rubber depends on the application requirements and material compatibility. Paste adhesives offer strong initial tack and flexibility, making them ideal for bonding uneven or porous surfaces, while dry rubber adhesives provide superior heat resistance and durability for high-stress or long-term applications. Understanding the specific demands of the project ensures optimal adhesion performance and longevity.

Paste vs Dry rubber adhesives Infographic

libmatt.com

libmatt.com