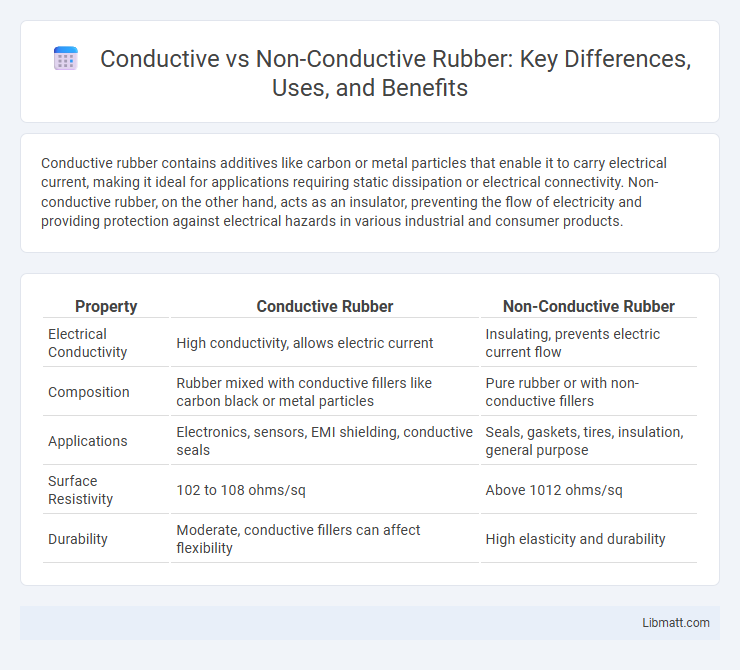

Conductive rubber contains additives like carbon or metal particles that enable it to carry electrical current, making it ideal for applications requiring static dissipation or electrical connectivity. Non-conductive rubber, on the other hand, acts as an insulator, preventing the flow of electricity and providing protection against electrical hazards in various industrial and consumer products.

Table of Comparison

| Property | Conductive Rubber | Non-Conductive Rubber |

|---|---|---|

| Electrical Conductivity | High conductivity, allows electric current | Insulating, prevents electric current flow |

| Composition | Rubber mixed with conductive fillers like carbon black or metal particles | Pure rubber or with non-conductive fillers |

| Applications | Electronics, sensors, EMI shielding, conductive seals | Seals, gaskets, tires, insulation, general purpose |

| Surface Resistivity | 102 to 108 ohms/sq | Above 1012 ohms/sq |

| Durability | Moderate, conductive fillers can affect flexibility | High elasticity and durability |

Introduction to Conductive and Non-conductive Rubber

Conductive rubber contains carbon particles or metallic fillers that allow the material to conduct electricity, making it ideal for applications like electrical grounding and EMI shielding. Non-conductive rubber, on the other hand, is formulated to resist electrical flow, providing insulation and protection in electrical and mechanical environments. Understanding the differences between these rubbers helps you choose the right material for safety and performance in your specific industrial or electronic applications.

Key Differences Between Conductive and Non-conductive Rubber

Conductive rubber contains conductive fillers like carbon or metal particles, enabling it to conduct electricity, while non-conductive rubber lacks these fillers and acts as an insulator. The key differences lie in electrical conductivity, with conductive rubber used in applications requiring static dissipation or grounding, and non-conductive rubber favored for insulation and protection against electrical currents. Your choice depends on whether you need to manage electrical charge or prevent electrical flow.

Composition and Manufacturing Processes

Conductive rubber incorporates additives like carbon black, metal particles, or conductive polymers to create pathways for electrical current, whereas non-conductive rubber relies on insulating materials such as natural or synthetic polymers without conductive fillers. Manufacturing conductive rubber involves compounding these conductive fillers evenly within the elastomer matrix through processes like mixing, extrusion, and vulcanization, ensuring consistent electrical properties. In contrast, non-conductive rubber production focuses on optimizing physical properties such as elasticity and durability through similar mixing and curing methods but excludes conductive additives.

Electrical Properties and Performance

Conductive rubber contains carbon black or metal particles that enable it to transmit electricity, making it ideal for applications requiring static dissipation or electromagnetic interference shielding. Non-conductive rubber, on the other hand, acts as an insulator with high resistance to electrical current, preventing conduction and protecting against electrical hazards. Selecting the right type of rubber directly affects Your device's electrical performance and safety in industrial or electronic environments.

Typical Applications of Conductive Rubber

Conductive rubber is widely used in electronic sealing, electromagnetic interference (EMI) shielding, and wearable sensor manufacturing due to its ability to conduct electricity while maintaining flexibility. It is essential in applications like flexible circuit boards, touch panels, and antistatic mats where electrical conductivity and durability are critical. In contrast, non-conductive rubber is preferred for insulation, gaskets, and vibration dampening, where electrical conductivity must be avoided.

Common Uses of Non-conductive Rubber

Non-conductive rubber is widely used in insulating materials for electrical applications, such as protective gloves, mats, and cable covers, to prevent electrical shocks and enhance safety. Its excellent dielectric properties make it ideal for automotive seals, gaskets, and hoses where resistance to electrical conductivity is crucial. Additionally, non-conductive rubber is commonly found in footwear soles and industrial vibration dampening components to provide insulation and reduce electrical hazards.

Advantages of Conductive Rubber in Industry

Conductive rubber offers superior electrical conductivity, making it essential for applications requiring static dissipation and electromagnetic interference (EMI) shielding in electronics manufacturing. Its durability and flexibility enhance performance in harsh industrial environments, reducing maintenance costs and downtime. The material's ability to maintain conductivity under mechanical stress ensures consistent functionality in sensors, connectors, and grounding components.

Benefits of Non-conductive Rubber in Commercial Settings

Non-conductive rubber offers superior electrical insulation, making it essential for maintaining safety in commercial environments with high electrical exposure. Your workplace benefits from reduced risk of electric shock and equipment damage, ensuring compliance with safety regulations. This material also provides excellent resistance to heat and chemicals, enhancing durability and reducing maintenance costs in industrial applications.

Choosing the Right Rubber for Your Application

Choosing the right rubber for your application depends on electrical conductivity requirements, mechanical properties, and environmental factors. Conductive rubber contains additives like carbon or metal particles to enable electrical flow, ideal for antistatic mats, EMI shielding, or sensor components. Non-conductive rubber offers excellent insulation, chemical resistance, and flexibility, making it suitable for sealing, gasketing, and vibration damping in non-electrical environments.

Future Trends in Rubber Technology

Future trends in rubber technology emphasize advances in conductive rubber materials incorporating nanomaterials like graphene and carbon nanotubes to enhance electrical conductivity and mechanical properties. Innovations in non-conductive rubber focus on eco-friendly, sustainable formulations with improved insulation and durability for automotive and electronics applications. Research into smart rubber composites promises multifunctional capabilities, such as self-healing and sensing, driving the next generation of both conductive and non-conductive rubber products.

Conductive vs Non-conductive rubber Infographic

libmatt.com

libmatt.com