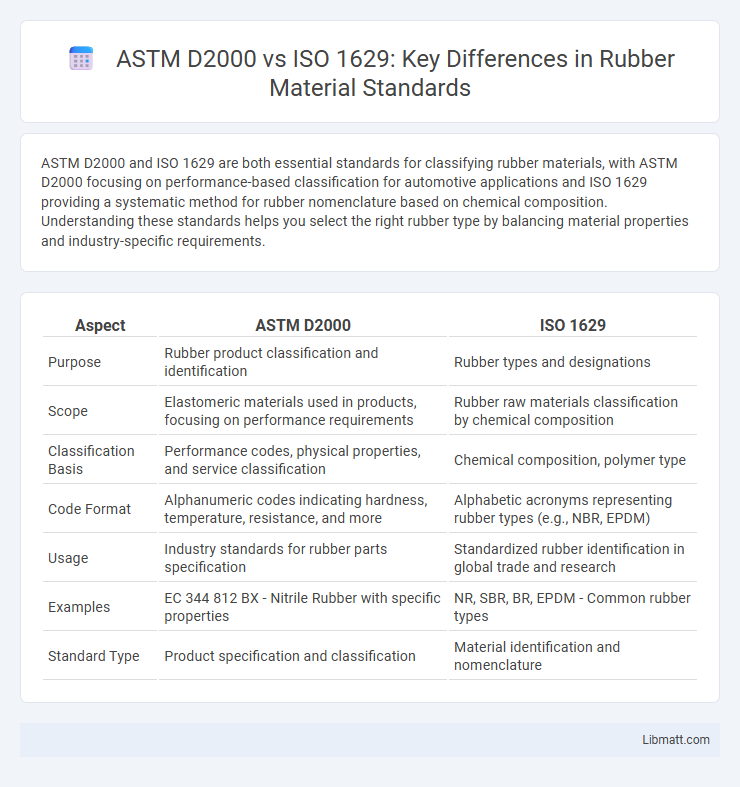

ASTM D2000 and ISO 1629 are both essential standards for classifying rubber materials, with ASTM D2000 focusing on performance-based classification for automotive applications and ISO 1629 providing a systematic method for rubber nomenclature based on chemical composition. Understanding these standards helps you select the right rubber type by balancing material properties and industry-specific requirements.

Table of Comparison

| Aspect | ASTM D2000 | ISO 1629 |

|---|---|---|

| Purpose | Rubber product classification and identification | Rubber types and designations |

| Scope | Elastomeric materials used in products, focusing on performance requirements | Rubber raw materials classification by chemical composition |

| Classification Basis | Performance codes, physical properties, and service classification | Chemical composition, polymer type |

| Code Format | Alphanumeric codes indicating hardness, temperature, resistance, and more | Alphabetic acronyms representing rubber types (e.g., NBR, EPDM) |

| Usage | Industry standards for rubber parts specification | Standardized rubber identification in global trade and research |

| Examples | EC 344 812 BX - Nitrile Rubber with specific properties | NR, SBR, BR, EPDM - Common rubber types |

| Standard Type | Product specification and classification | Material identification and nomenclature |

Introduction to ASTM D2000 and ISO 1629

ASTM D2000 is a classification system developed by the American Society for Testing and Materials, providing standardized grades for rubber materials based on properties such as hardness, tensile strength, and temperature resistance. ISO 1629, established by the International Organization for Standardization, defines a systematic nomenclature for rubber and elastomers, categorizing them by chemical structure. Both standards serve critical roles in ensuring material consistency and quality in rubber manufacturing and engineering applications worldwide.

Overview of ASTM D2000 Standard

ASTM D2000 is a classification system utilized primarily for rubber products, specifying grades based on physical properties such as hardness, tensile strength, and resistance to heat, oil, and ozone. This standard organizes rubber materials into performance classes, facilitating uniformity and quality control in manufacturing and engineering applications. Unlike ISO 1629, which is a classification system for rubber types by their chemical composition and generic identification, ASTM D2000 focuses on the end-use properties critical for selecting appropriate elastomers in industrial settings.

Overview of ISO 1629 Standard

ISO 1629 standard provides a systematic method for classifying rubber materials based on their chemical composition and properties, facilitating consistent identification and communication across industries. It defines precise codes and symbols for various elastomers, enabling efficient material selection and quality control in manufacturing and testing processes. By standardizing elastomer nomenclature, ISO 1629 enhances global compatibility and streamlines technical documentation in polymer and rubber engineering fields.

Key Differences Between ASTM D2000 and ISO 1629

ASTM D2000 provides a detailed classification system specifically for rubber materials based on properties such as hardness, tensile strength, and elongation, while ISO 1629 offers a broader classification and designation system primarily for rubber types and compound identification. ASTM D2000 emphasizes performance requirements and testing methods tailored for automotive rubber components, whereas ISO 1629 focuses on standardized rubber nomenclature and general material identification globally. The key difference lies in ASTM D2000's performance-oriented criteria for engineering applications versus ISO 1629's role as an international standard for rubber classification and terminology.

Material Classification Methods

ASTM D2000 classifies rubber materials based on a comprehensive system of letter and number codes that specify properties like hardness, temperature range, and chemical resistance, enabling precise identification of elastomers for industrial applications. ISO 1629 employs a standardized nomenclature system that identifies rubber types by abbreviations corresponding to their chemical composition, facilitating global consistency in material classification. Your choice between these standards depends on whether detailed property classification or simplified chemical identification best suits your material selection needs.

Application Areas for Each Standard

ASTM D2000 mainly applies to rubber materials used in automotive, aerospace, and industrial sectors where specific performance criteria such as temperature resistance and elasticity are critical. ISO 1629 focuses on the classification and designation of rubber types, serving as a fundamental reference in manufacturing, quality control, and research across various industries including medical, consumer goods, and electronics. Understanding these standards ensures Your selection of rubber materials aligns with industry-specific application requirements and technical specifications.

Advantages of ASTM D2000

ASTM D2000 offers a comprehensive classification system for rubber materials, providing precise guidelines on physical properties, chemical resistance, and performance criteria that enhance material selection accuracy. This standard enables manufacturers and engineers to ensure consistent quality and compatibility for automotive and industrial applications. Your ability to specify ASTM D2000 grades helps optimize product reliability and durability compared to the broader categorization in ISO 1629.

Advantages of ISO 1629

ISO 1629 offers a globally consistent method for classifying rubber materials based on chemical composition, improving clarity and reducing confusion in international trade. You benefit from its straightforward coding system, which facilitates easier identification and comparison of rubber types across diverse industries. This standard supports enhanced quality control and material selection, promoting efficiency in manufacturing and product development.

Cross-Referencing ASTM D2000 with ISO 1629

Cross-referencing ASTM D2000 with ISO 1629 requires understanding the distinct classification systems each standard uses for rubber materials. ASTM D2000 categorizes rubber based on property requirements and performance grades, while ISO 1629 provides a systematic rubber nomenclature by type and structure. Your ability to match ASTM grades to ISO rubber types ensures accurate material selection and compliance across international specifications.

Choosing the Right Standard for Your Application

Selecting between ASTM D2000 and ISO 1629 depends on the application requirements and regional standards adherence; ASTM D2000 offers a comprehensive rubber classification system widely accepted in North America, whereas ISO 1629 provides a systematic rubber identification method preferred internationally. ASTM D2000's detailed grading, based on physical and mechanical properties, suits industries needing precise rubber specifications for automotive and industrial use. ISO 1629 simplifies rubber types into categories, ideal for applications requiring consistent material identification and global interoperability.

ASTM D2000 vs ISO 1629 Infographic

libmatt.com

libmatt.com