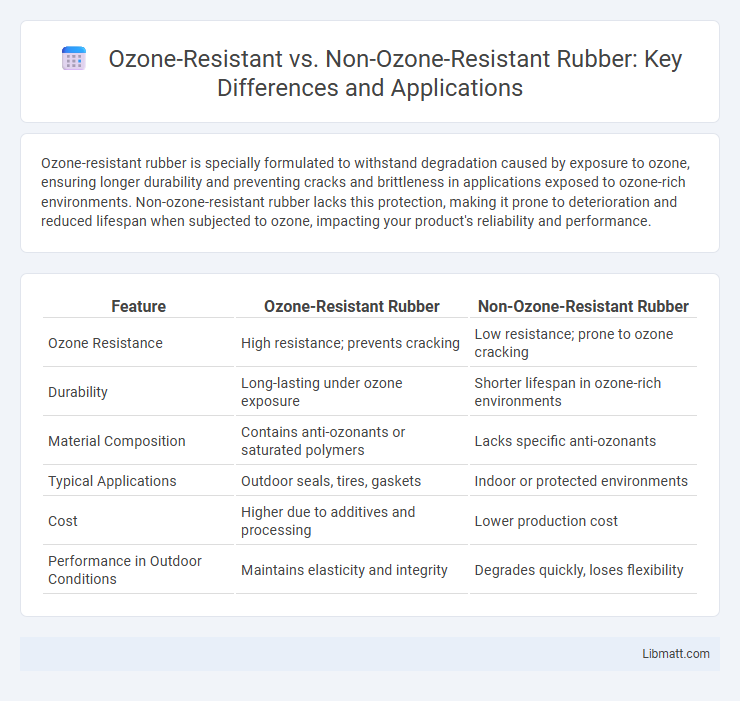

Ozone-resistant rubber is specially formulated to withstand degradation caused by exposure to ozone, ensuring longer durability and preventing cracks and brittleness in applications exposed to ozone-rich environments. Non-ozone-resistant rubber lacks this protection, making it prone to deterioration and reduced lifespan when subjected to ozone, impacting your product's reliability and performance.

Table of Comparison

| Feature | Ozone-Resistant Rubber | Non-Ozone-Resistant Rubber |

|---|---|---|

| Ozone Resistance | High resistance; prevents cracking | Low resistance; prone to ozone cracking |

| Durability | Long-lasting under ozone exposure | Shorter lifespan in ozone-rich environments |

| Material Composition | Contains anti-ozonants or saturated polymers | Lacks specific anti-ozonants |

| Typical Applications | Outdoor seals, tires, gaskets | Indoor or protected environments |

| Cost | Higher due to additives and processing | Lower production cost |

| Performance in Outdoor Conditions | Maintains elasticity and integrity | Degrades quickly, loses flexibility |

Introduction to Ozone-resistant and Non-ozone-resistant Rubber

Ozone-resistant rubber is specially formulated to withstand the deteriorating effects of ozone exposure, preventing cracking and maintaining elasticity over time, which is crucial for outdoor applications and automotive parts. In contrast, non-ozone-resistant rubber lacks additives that protect against ozone damage, making it susceptible to weathering and premature failure when exposed to ozone-rich environments. Choosing the right type ensures Your products perform reliably under environmental stress, extending service life and reducing maintenance costs.

Defining Ozone Resistance in Rubber Materials

Ozone-resistant rubber materials are specifically formulated to withstand the degrading effects of ozone exposure, which causes surface cracking and deterioration in non-ozone-resistant rubbers. This resistance is achieved through the incorporation of additives, like antiozonants, and the use of polymers with high unsaturation stability such as EPDM (ethylene propylene diene monomer) rubber. Defining ozone resistance involves evaluating the rubber's ability to maintain mechanical properties and surface integrity after prolonged ozone exposure, ensuring longevity in applications exposed to atmospheric ozone levels.

Chemical Composition and Structure Differences

Ozone-resistant rubber typically contains polymers such as EPDM (ethylene propylene diene monomer) or neoprene, which incorporate unsaturated sites with stabilizers or more saturated backbones to minimize ozone attack, whereas non-ozone-resistant rubbers like natural rubber or styrene-butadiene rubber (SBR) have higher concentrations of double bonds in their polymer chains that are more susceptible to ozone-induced cracking. The chemical structure of ozone-resistant rubber is characterized by fewer or protected carbon-carbon double bonds, enhancing molecular stability against ozone oxidation. In contrast, non-ozone-resistant rubber's unsaturated diene units create vulnerabilities where ozone molecules initiate chain scission, resulting in surface cracking and degradation.

Common Types of Ozone-resistant Rubber

EPDM (Ethylene Propylene Diene Monomer) rubber is a common ozone-resistant type known for its excellent resistance to ozone, weathering, and UV exposure, making it ideal for outdoor applications. Nitrile rubber (NBR) variants can be formulated to enhance ozone resistance while maintaining strong oil resistance, often used in automotive and industrial seals. Silicone rubber also exhibits good ozone resistance along with high temperature stability, frequently utilized in aerospace and medical devices.

Typical Applications of Ozone-resistant Rubber

Ozone-resistant rubber is commonly used in automotive tires, seals, hoses, and conveyor belts where exposure to ozone can cause cracking and degradation. Its enhanced durability ensures longer service life in outdoor and industrial environments, protecting equipment from ozone-induced damage. You benefit from improved performance and reduced maintenance costs when choosing ozone-resistant rubber for these high-stress applications.

Limitations and Use Cases of Non-ozone-resistant Rubber

Non-ozone-resistant rubber degrades rapidly when exposed to ozone, resulting in cracking and loss of mechanical properties, limiting its durability in environments with significant ozone presence. This type of rubber is best suited for indoor applications or areas with minimal ozone exposure, such as seals or gaskets inside buildings or machinery shielded from outdoor air pollutants. Non-ozone-resistant rubber is often chosen for cost-sensitive projects where long-term exposure and environmental factors are controlled or negligible.

Environmental Impact on Rubber Performance

Ozone-resistant rubber, such as EPDM and silicone, maintains structural integrity and flexibility when exposed to ozone-rich environments, preventing cracks and prolonging lifespan, which reduces waste and environmental pollution. Non-ozone-resistant rubber, like natural rubber and SBR, degrades quickly under ozone exposure, leading to frequent replacements and higher environmental impact from increased manufacturing and disposal processes. Selecting ozone-resistant rubber enhances durability and sustainability by minimizing resource consumption and environmental degradation over time.

Durability and Lifespan Comparison

Ozone-resistant rubber demonstrates superior durability compared to non-ozone-resistant rubber due to its enhanced ability to withstand ozone-induced cracking and degradation. This resistance significantly extends the lifespan of ozone-resistant rubber products, especially in outdoor or industrial environments with high ozone exposure. Non-ozone-resistant rubber typically suffers from faster deterioration, leading to more frequent replacements and increased maintenance costs.

Cost Considerations and Economic Benefits

Ozone-resistant rubber typically costs more upfront due to specialized additives and manufacturing processes but offers longer service life and reduced maintenance expenses, resulting in lower total ownership costs. Non-ozone-resistant rubber, while initially cheaper, often suffers from cracks and degradation when exposed to ozone, leading to frequent replacements and higher long-term operational costs. Investing in ozone-resistant rubber can optimize economic benefits by minimizing downtime and ensuring durability in ozone-prone environments.

Choosing the Right Rubber for Your Application

Ozone-resistant rubber, such as EPDM and silicone, offers superior durability in environments exposed to ozone, UV light, and harsh weather, making it ideal for outdoor applications like seals, gaskets, and automotive parts. Non-ozone-resistant rubber, like natural rubber or standard NBR, is suitable for indoor or low-ozone environments where flexibility and cost-effectiveness are prioritized over long-term oxidation resistance. Selecting the right rubber involves assessing environmental exposure, mechanical requirements, and lifespan expectations to ensure optimal performance and durability in your specific application.

Ozone-resistant vs Non-ozone-resistant rubber Infographic

libmatt.com

libmatt.com