Hot vulcanization uses elevated temperatures to rapidly cure rubber, creating strong, durable bonds ideal for industrial applications, while cold vulcanization cures at room temperature with chemical adhesives, offering convenience and flexibility for on-site repairs. Your choice depends on the required bond strength, curing time, and application environment.

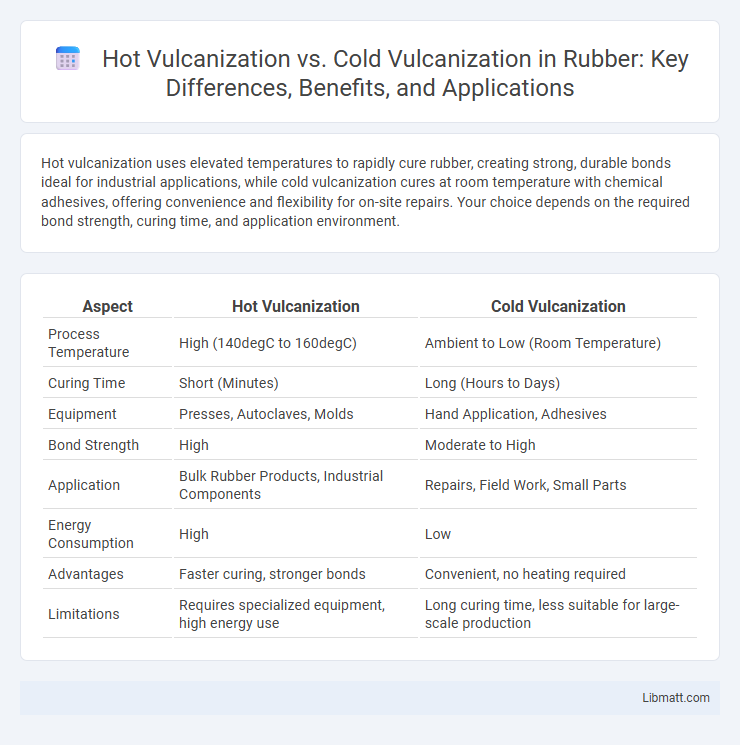

Table of Comparison

| Aspect | Hot Vulcanization | Cold Vulcanization |

|---|---|---|

| Process Temperature | High (140degC to 160degC) | Ambient to Low (Room Temperature) |

| Curing Time | Short (Minutes) | Long (Hours to Days) |

| Equipment | Presses, Autoclaves, Molds | Hand Application, Adhesives |

| Bond Strength | High | Moderate to High |

| Application | Bulk Rubber Products, Industrial Components | Repairs, Field Work, Small Parts |

| Energy Consumption | High | Low |

| Advantages | Faster curing, stronger bonds | Convenient, no heating required |

| Limitations | Requires specialized equipment, high energy use | Long curing time, less suitable for large-scale production |

Introduction to Vulcanization

Vulcanization is a chemical process that improves the elasticity and strength of rubber by forming cross-links between polymer chains. Hot vulcanization uses elevated temperatures, typically between 140degC and 160degC, to speed up this cross-linking process, resulting in faster curing and enhanced mechanical properties. Cold vulcanization, performed at room temperature with specialized chemicals, offers a slower curing time but is ideal for on-site repairs and applications where heat exposure is limited.

What is Hot Vulcanization?

Hot vulcanization is a process that uses elevated temperatures and pressure to cure rubber compounds, creating strong chemical bonds between polymer chains. This method typically requires a vulcanizing press or autoclave, enabling faster curing times and enhanced mechanical properties in the final product. Your rubber materials benefit from improved durability and elasticity through precise temperature control during hot vulcanization.

What is Cold Vulcanization?

Cold vulcanization is a chemical process used to repair or join rubber materials without applying heat, utilizing solvent-based adhesives or liquid rubber compounds that cure at room temperature. This method is essential for on-site repairs of tires, conveyor belts, and other rubber products, offering quick bonding and minimal downtime. Cold vulcanization provides flexibility and strong adhesion, making it suitable for delicate or heat-sensitive materials where hot vulcanization would be impractical.

Key Differences Between Hot and Cold Vulcanization

Hot vulcanization involves curing rubber using heat and pressure, resulting in faster cross-linking and stronger mechanical properties, while cold vulcanization uses chemical agents at ambient temperatures for bonding, offering easier application but longer curing times. The temperature and pressure conditions distinguish hot vulcanization as ideal for producing durable, high-performance rubber products, whereas cold vulcanization suits repairs and maintenance where heat application is impractical. Understanding these differences helps you choose the right vulcanization method for your specific rubber processing or repair needs.

Materials Used in Hot vs Cold Vulcanization

Hot vulcanization typically uses natural rubber or synthetic elastomers combined with sulfur and accelerators, requiring heat and pressure to form strong cross-links within the material. Cold vulcanization involves using room-temperature curing adhesives, often based on resorcinol or neoprene, which bond rubber surfaces without needing elevated temperatures. The choice of materials depends on application demands, with hot vulcanization providing superior durability while cold vulcanization offers convenience for repairs and quick bonding.

Process Steps: Hot Vulcanization

Hot vulcanization involves heating rubber with sulfur at temperatures typically between 140degC and 160degC, which accelerates the cross-linking process to enhance elasticity and strength. The process steps include mixing raw rubber with vulcanizing agents, molding the rubber into the desired shape, and then applying heat and pressure in a heated press or autoclave to initiate vulcanization. Your choice of hot vulcanization ensures faster curing times and improved mechanical properties compared to cold vulcanization techniques.

Process Steps: Cold Vulcanization

Cold vulcanization involves applying a sulfur-based adhesive or curing agent directly to the rubber surface, allowing it to cure at room temperature without external heat. The process typically includes surface cleaning, adhesive application, joining rubber parts, and maintaining pressure to ensure a durable bond. Unlike hot vulcanization, cold vulcanization requires longer curing times but offers advantages in convenience and suitability for on-site repairs.

Advantages of Hot Vulcanization

Hot vulcanization offers superior bonding strength and durability compared to cold vulcanization, making it ideal for heavy-duty rubber repairs and industrial applications. The elevated temperature accelerates the cross-linking process in rubber compounds, resulting in enhanced mechanical properties and extended product lifespan. This method also ensures a more uniform cure and minimizes the risk of incomplete vulcanization, which is critical for maintaining material integrity in high-stress environments.

Benefits of Cold Vulcanization

Cold vulcanization offers significant benefits including ease of application without the need for high temperatures, making it ideal for on-site repairs and maintenance of conveyor belts and rubber products. This method reduces energy consumption and avoids heat-related risks, ensuring safer operations and extended equipment lifespan. Its ability to create strong, flexible, and durable bonds enhances operational efficiency in industries such as mining, manufacturing, and transportation.

Choosing the Right Vulcanization Method

Choosing the right vulcanization method depends on factors like application speed, equipment availability, and rubber type. Hot vulcanization offers faster curing and stronger bonds, ideal for industrial-scale production, while cold vulcanization is more flexible and suitable for on-site repairs or delicate materials. Your choice will ultimately impact durability and efficiency in rubber product performance.

Hot Vulcanization vs Cold Vulcanization Infographic

libmatt.com

libmatt.com