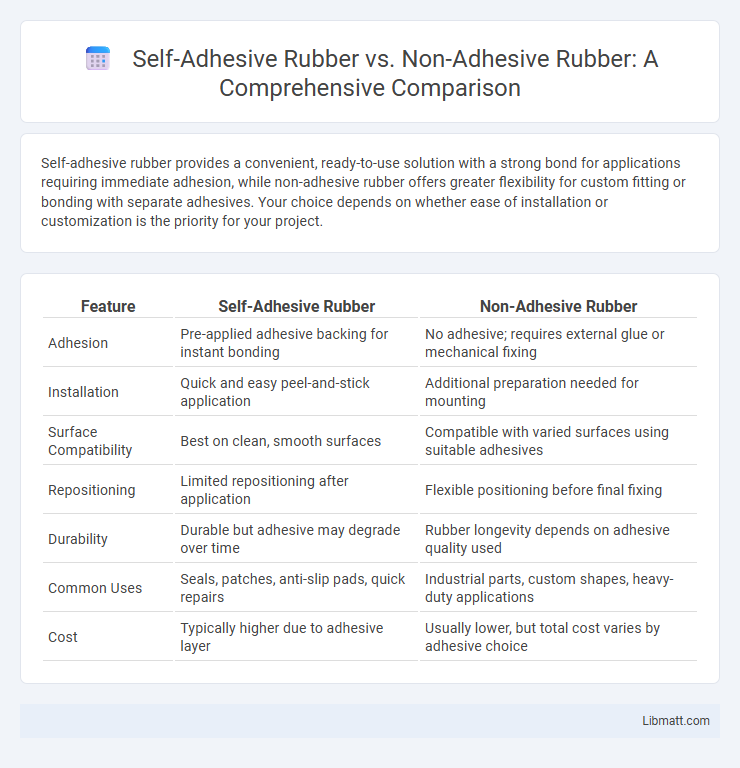

Self-adhesive rubber provides a convenient, ready-to-use solution with a strong bond for applications requiring immediate adhesion, while non-adhesive rubber offers greater flexibility for custom fitting or bonding with separate adhesives. Your choice depends on whether ease of installation or customization is the priority for your project.

Table of Comparison

| Feature | Self-Adhesive Rubber | Non-Adhesive Rubber |

|---|---|---|

| Adhesion | Pre-applied adhesive backing for instant bonding | No adhesive; requires external glue or mechanical fixing |

| Installation | Quick and easy peel-and-stick application | Additional preparation needed for mounting |

| Surface Compatibility | Best on clean, smooth surfaces | Compatible with varied surfaces using suitable adhesives |

| Repositioning | Limited repositioning after application | Flexible positioning before final fixing |

| Durability | Durable but adhesive may degrade over time | Rubber longevity depends on adhesive quality used |

| Common Uses | Seals, patches, anti-slip pads, quick repairs | Industrial parts, custom shapes, heavy-duty applications |

| Cost | Typically higher due to adhesive layer | Usually lower, but total cost varies by adhesive choice |

Introduction to Self-Adhesive and Non-Adhesive Rubber

Self-adhesive rubber features a tacky backing that enables easy application without extra bonding agents, commonly used in seals, gaskets, and protective covers. Non-adhesive rubber requires separate adhesives or mechanical fastening for attachment, offering versatility in industrial and automotive applications. Both types provide elasticity, durability, and resistance to environmental factors, but selection depends on installation requirements and end-use scenarios.

Defining Self-Adhesive Rubber

Self-adhesive rubber features a pressure-sensitive adhesive backing that allows it to bond securely to various surfaces without requiring additional glue or heat. This material is commonly used for quick installation in applications such as sealing, vibration damping, and mounting where ease of use and strong adhesion are critical. Understanding the benefits of self-adhesive rubber helps you select the right product for efficient, durable, and clean application.

What is Non-Adhesive Rubber?

Non-adhesive rubber is a type of elastomeric material that lacks any sticky or tacky surface, making it ideal for applications where no bonding to surfaces is required. Unlike self-adhesive rubber, which contains a pressure-sensitive adhesive layer, non-adhesive rubber offers flexibility, durability, and resistance to wear without leaving residue upon removal. Your choice between self-adhesive and non-adhesive rubber depends on whether you need a temporary or permanent attachment solution.

Key Material Differences

Self-adhesive rubber incorporates a pressure-sensitive adhesive layer allowing easy application and strong bonding to various surfaces, whereas non-adhesive rubber requires separate adhesives or mechanical fastening for attachment. The adhesive layer in self-adhesive rubber often comprises synthetic resins that maintain tackiness and durability, contrasting with non-adhesive rubber's pure elastomer base, which offers enhanced flexibility and resilience. Your choice between the two depends on whether you prioritize convenience and quick installation or require customizable bonding methods and potentially higher material flexibility.

Installation Process: Self-Adhesive vs Non-Adhesive

Self-adhesive rubber simplifies the installation process by requiring no additional adhesives or tools, as its backing is pre-coated with a strong adhesive layer that bonds directly to surfaces. Non-adhesive rubber demands extra preparation, including applying glue or other bonding agents, and precise alignment to ensure a secure fit. Choosing self-adhesive rubber can save you time and reduce installation errors compared to the more labor-intensive non-adhesive option.

Applications and Uses

Self-adhesive rubber is ideal for applications requiring quick installation and repositioning, such as mounting gaskets, seals, and vibration dampening pads, commonly used in automotive, electronics, and household repairs. Non-adhesive rubber is preferred for custom fabrication, industrial machinery parts, and heavy-duty sealing where strong mechanical fastening or bonding is necessary. Your choice depends on whether ease of application or long-term durability in demanding environments is the priority.

Durability and Performance Comparison

Self-adhesive rubber offers enhanced durability due to its integrated adhesive layer, which provides strong bonding and reduces the risk of slippage or detachment in various applications. Non-adhesive rubber, while flexible and resistant to wear, generally requires additional fastening methods that can compromise overall performance and longevity. Performance testing shows self-adhesive rubber excels in maintaining seal integrity and vibration dampening under dynamic conditions compared to non-adhesive variants.

Cost Effectiveness: Which Is More Economical?

Self-adhesive rubber offers greater cost effectiveness by eliminating the need for additional bonding agents or external adhesives, reducing installation time and labor expenses. Non-adhesive rubber typically requires separate adhesives, increasing both material costs and application complexity. Your choice depends on balancing initial material savings with potential labor and durability considerations in your specific project.

Pros and Cons of Each Type

Self-adhesive rubber offers easy application and strong initial bonding, making it ideal for quick fixes and temporary uses, but may leave residue and lose adhesion over time. Non-adhesive rubber provides superior durability and flexibility without sticky residues, suitable for long-term projects or harsh environments, though it requires additional adhesives or mechanical fasteners for attachment. Understanding these pros and cons helps you choose the right rubber type for your specific application needs.

Choosing the Right Rubber for Your Project

Selecting between self-adhesive rubber and non-adhesive rubber depends on your project's application requirements and installation preferences. Self-adhesive rubber offers easy, residue-free application ideal for quick fixes or areas needing strong initial tack, while non-adhesive rubber provides flexibility for custom bonding methods and can withstand higher temperatures or chemical exposure. Evaluating factors like surface compatibility, environmental conditions, and long-term durability ensures you choose the most effective rubber type for your specific needs.

Self-Adhesive Rubber vs Non-Adhesive Rubber Infographic

libmatt.com

libmatt.com