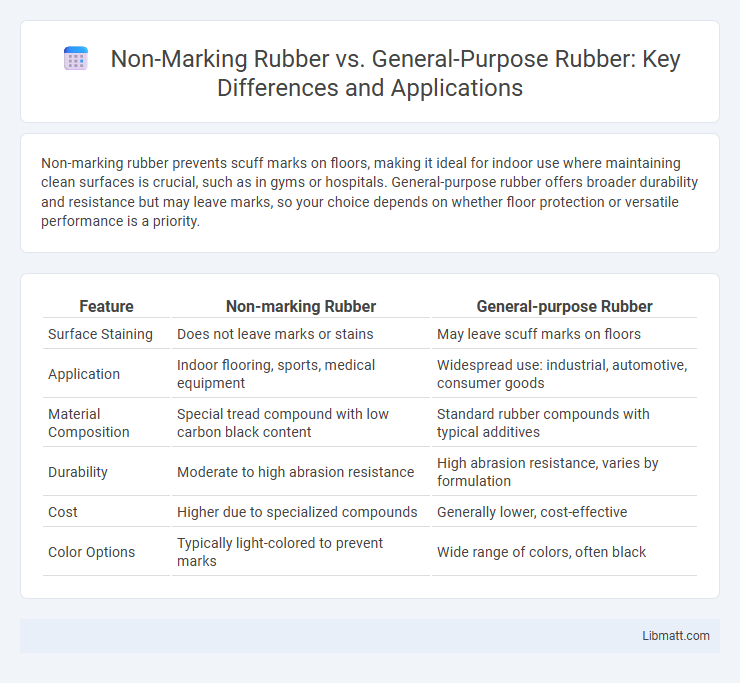

Non-marking rubber prevents scuff marks on floors, making it ideal for indoor use where maintaining clean surfaces is crucial, such as in gyms or hospitals. General-purpose rubber offers broader durability and resistance but may leave marks, so your choice depends on whether floor protection or versatile performance is a priority.

Table of Comparison

| Feature | Non-marking Rubber | General-purpose Rubber |

|---|---|---|

| Surface Staining | Does not leave marks or stains | May leave scuff marks on floors |

| Application | Indoor flooring, sports, medical equipment | Widespread use: industrial, automotive, consumer goods |

| Material Composition | Special tread compound with low carbon black content | Standard rubber compounds with typical additives |

| Durability | Moderate to high abrasion resistance | High abrasion resistance, varies by formulation |

| Cost | Higher due to specialized compounds | Generally lower, cost-effective |

| Color Options | Typically light-colored to prevent marks | Wide range of colors, often black |

Understanding Non-marking Rubber

Non-marking rubber is specifically formulated to prevent leaving scuff marks or stains on floors, making it ideal for indoor applications such as in gyms, hospitals, and food processing areas. Unlike general-purpose rubber, non-marking rubber features a different compound with lower abrasive particles and enhanced resilience to maintain floor aesthetics and cleanliness. Its unique non-marking properties ensure long-lasting performance without compromising grip or durability on smooth surfaces.

What Is General-purpose Rubber?

General-purpose rubber is a versatile elastomer commonly used for seals, gaskets, and hoses due to its balanced properties of flexibility, durability, and cost-effectiveness. Unlike non-marking rubber, which is designed to prevent scuffing and leaving marks on floors, general-purpose rubber prioritizes broad applicability in various industrial and consumer products. Understanding the differences helps you select the right material for applications requiring specific performance characteristics.

Key Differences Between Non-marking and General-purpose Rubber

Non-marking rubber is specifically designed to prevent scuff marks and stains on floors, making it ideal for indoor use in environments like gyms and hospitals, whereas general-purpose rubber offers broader applications with higher durability but may leave marks during use. The composition of non-marking rubber often includes specialized additives that reduce surface abrasion and color transfer, unlike general-purpose rubber which prioritizes toughness and resistance to wear. Choosing non-marking rubber ensures your floors remain clean and unblemished, while general-purpose rubber provides versatile protection in outdoor and heavy-duty industrial settings.

Advantages of Non-marking Rubber

Non-marking rubber offers superior surface protection by preventing unsightly scuff marks and stains on floors, making it ideal for indoor environments like gyms, hospitals, and schools. Its enhanced abrasion resistance and non-slip properties improve safety and durability compared to general-purpose rubber. You benefit from cleaner surfaces and longer-lasting flooring without compromising on grip or performance.

Common Uses for Non-marking Rubber

Non-marking rubber is primarily used in environments requiring clean, scuff-free floors such as hospitals, schools, and sports facilities. Its unique formulation prevents black marks on surfaces, making it ideal for casters, wheels, and flooring applications where maintaining appearance is crucial. If you need durable rubber that won't leave marks on your floors, non-marking rubber offers the best performance for sensitive flooring areas.

Applications of General-purpose Rubber

General-purpose rubber is widely used in automotive parts, household appliances, and industrial machinery due to its excellent balance of durability, flexibility, and resistance to wear and tear. It is ideal for products like gaskets, seals, hoses, and vibration dampers where moderate performance and cost-effectiveness are essential. You can rely on general-purpose rubber for everyday applications that do not require the specialized properties of non-marking rubber.

Durability: Non-marking vs General-purpose Rubber

Non-marking rubber is engineered with specialized compounds that provide enhanced durability while preventing scuff marks on surfaces, making it ideal for applications requiring floor protection. General-purpose rubber, though durable, tends to wear faster under abrasive conditions and may leave marks, limiting its effectiveness in sensitive environments. You will find non-marking rubber offers superior longevity and surface preservation compared to general-purpose rubber in high-traffic or specialized settings.

Cost Comparison: Which Rubber is More Economical?

Non-marking rubber typically costs more than general-purpose rubber due to its specialized formulation that prevents surface staining, making it ideal for sensitive flooring environments. General-purpose rubber, being more widely produced and less specialized, offers a more economical option for applications where surface marking is not a concern. Your decision should weigh the initial cost against the long-term benefits, especially if avoiding floor damage reduces maintenance expenses.

Choosing the Right Rubber for Your Needs

Non-marking rubber is ideal for environments where floor cleanliness and appearance matter most, as it prevents scuff marks and stains often caused by general-purpose rubber. General-purpose rubber offers durability and versatility for heavy-duty applications but may leave marks on sensitive surfaces. Understanding your floor type and application will help you choose the right rubber to protect your investment and maintain aesthetics.

Maintenance and Care Tips for Rubber Products

Non-marking rubber requires gentle cleaning with mild soap and water to prevent surface damage and preserve its color and texture, while general-purpose rubber can tolerate more robust cleaning methods, including pressure washing or chemical cleaners. Avoid prolonged exposure to UV light and extreme temperatures for both types to extend their lifespan and maintain flexibility. You can prolong the performance of your rubber products by storing them in a cool, dry place away from direct sunlight and performing regular inspections for wear or degradation.

Non-marking Rubber vs General-purpose Rubber Infographic

libmatt.com

libmatt.com