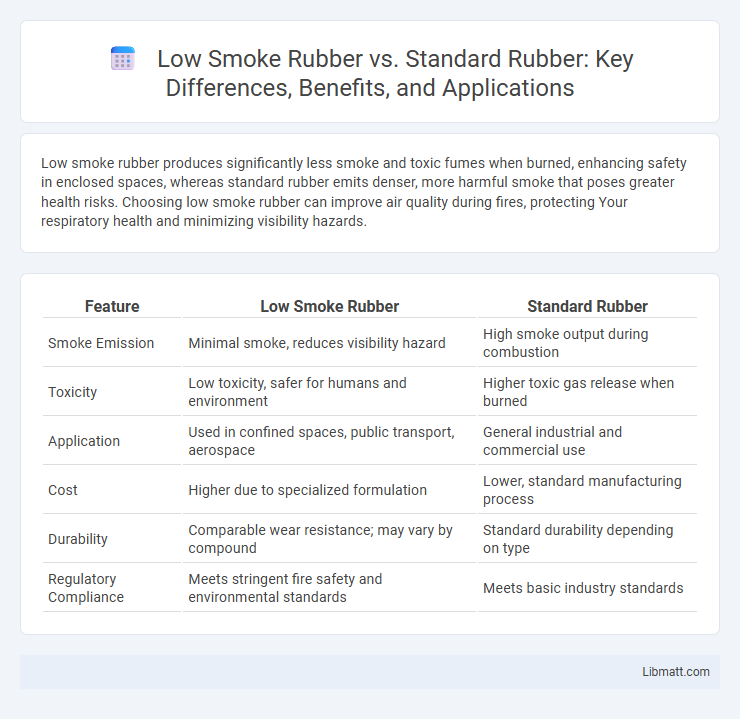

Low smoke rubber produces significantly less smoke and toxic fumes when burned, enhancing safety in enclosed spaces, whereas standard rubber emits denser, more harmful smoke that poses greater health risks. Choosing low smoke rubber can improve air quality during fires, protecting Your respiratory health and minimizing visibility hazards.

Table of Comparison

| Feature | Low Smoke Rubber | Standard Rubber |

|---|---|---|

| Smoke Emission | Minimal smoke, reduces visibility hazard | High smoke output during combustion |

| Toxicity | Low toxicity, safer for humans and environment | Higher toxic gas release when burned |

| Application | Used in confined spaces, public transport, aerospace | General industrial and commercial use |

| Cost | Higher due to specialized formulation | Lower, standard manufacturing process |

| Durability | Comparable wear resistance; may vary by compound | Standard durability depending on type |

| Regulatory Compliance | Meets stringent fire safety and environmental standards | Meets basic industry standards |

Introduction to Low Smoke Rubber and Standard Rubber

Low smoke rubber is engineered to emit significantly less smoke and toxic gases when exposed to fire, making it ideal for enhancing safety in enclosed or high-risk environments. Standard rubber, while commonly used for its durability and flexibility, releases higher levels of dense smoke and harmful substances during combustion. Understanding the differences in composition and fire behavior helps you select the appropriate rubber type for safety-critical applications.

Key Differences in Composition

Low smoke rubber differs from standard rubber primarily in its formulation, incorporating halogen-free compounds and additives that significantly reduce smoke density and toxicity during combustion. Standard rubber typically contains conventional fillers and plasticizers, which release denser, more hazardous smoke when burned. Your choice between these materials impacts safety and environmental compliance, especially in enclosed or high-risk environments.

Fire Safety and Smoke Emissions

Low smoke rubber significantly enhances fire safety by emitting substantially less toxic smoke and harmful gases during combustion compared to standard rubber. This reduced smoke emission improves visibility and air quality in fire emergencies, facilitating safer and quicker evacuations. Consequently, low smoke rubber is widely preferred in environments with strict fire safety regulations, such as public transportation and high-occupancy buildings.

Environmental Impact Comparison

Low smoke rubber releases significantly fewer harmful emissions and particulate matter compared to standard rubber, resulting in improved air quality and reduced health risks during combustion or fire incidents. Its reduced toxic smoke output minimizes environmental pollution and enhances safety in enclosed spaces or urban areas. Choosing low smoke rubber contributes to mitigating the ecological footprint of your products and aligns with sustainable manufacturing practices.

Performance and Durability

Low smoke rubber offers superior fire safety by emitting minimal toxic fumes during combustion, enhancing performance in environments where air quality and visibility are crucial. It maintains comparable durability to standard rubber, resisting abrasion, heat, and chemical exposure effectively for long-lasting use. Your choice of low smoke rubber ensures safer, more reliable performance without compromising on wear resistance.

Applications and Industry Usage

Low smoke rubber is preferred in industries such as transportation, construction, and electronics where fire safety and minimal toxic emissions during combustion are critical. Standard rubber finds extensive use in general manufacturing, automotive parts, and consumer goods where cost-efficiency and mechanical durability are prioritized over smoke emission levels. The choice between low smoke and standard rubber depends significantly on regulatory requirements and environmental safety standards specific to the application sector.

Regulatory Standards and Compliance

Low smoke rubber complies with stringent fire safety regulations such as UL 94V-0 and EN 45545-2, designed to limit smoke density and toxic gas emissions in fire scenarios. Standard rubber often meets basic industry standards like ASTM D2000 but lacks specific certifications for smoke suppression and toxicity reduction. Compliance with these regulatory standards makes low smoke rubber essential in transportation, construction, and electronics where fire safety and minimal smoke generation are critical.

Cost Analysis: Low Smoke vs Standard Rubber

Low smoke rubber typically incurs higher initial costs compared to standard rubber due to specialized additives that reduce smoke and toxic emissions during combustion. Despite the premium price, low smoke rubber offers long-term savings by enhancing safety in environments where fire hazards are critical, potentially reducing insurance premiums and compliance costs. Your choice between low smoke and standard rubber should balance upfront investment with the safety benefits and regulatory requirements of your specific application.

Installation and Maintenance Considerations

Low smoke rubber simplifies installation by reducing the need for specialized ventilation systems, enhancing safety during handling and fitting in enclosed spaces. Its maintenance is more straightforward due to lower emissions of harmful fumes when heated or worn, minimizing health risks for workers and prolonging equipment lifespan. Choosing low smoke rubber can protect Your workforce and reduce long-term maintenance costs compared to standard rubber alternatives.

Future Trends in Rubber Technology

Low smoke rubber is gaining traction due to increasing regulations on fire safety and environmental impact, driving innovation toward materials that emit fewer toxic fumes during combustion. Standard rubber formulations are gradually being enhanced or replaced by low smoke alternatives in industries such as automotive, construction, and aerospace to meet stricter health and safety standards. Your investment in products made with low smoke rubber aligns with the future trend of sustainable, safer materials designed for enhanced performance and reduced environmental footprint.

Low smoke rubber vs Standard rubber Infographic

libmatt.com

libmatt.com