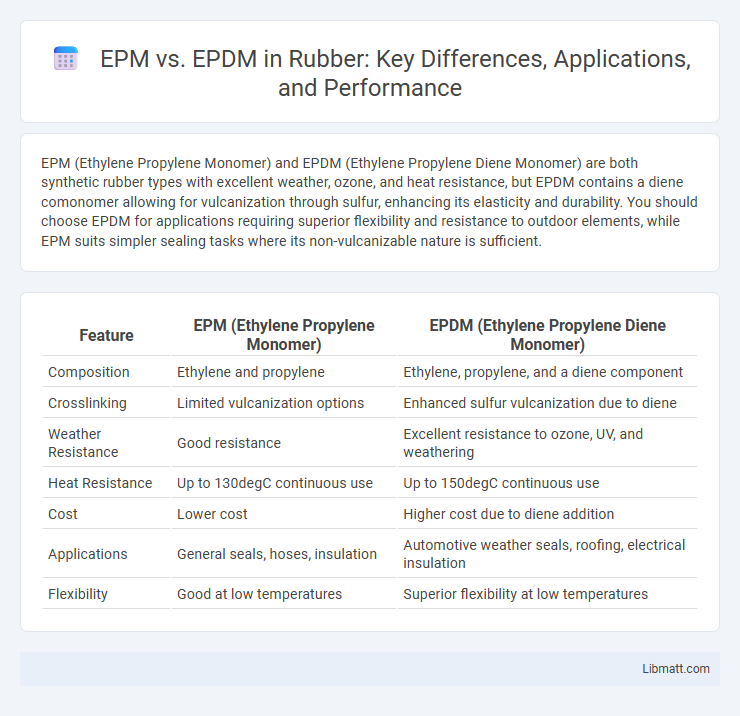

EPM (Ethylene Propylene Monomer) and EPDM (Ethylene Propylene Diene Monomer) are both synthetic rubber types with excellent weather, ozone, and heat resistance, but EPDM contains a diene comonomer allowing for vulcanization through sulfur, enhancing its elasticity and durability. You should choose EPDM for applications requiring superior flexibility and resistance to outdoor elements, while EPM suits simpler sealing tasks where its non-vulcanizable nature is sufficient.

Table of Comparison

| Feature | EPM (Ethylene Propylene Monomer) | EPDM (Ethylene Propylene Diene Monomer) |

|---|---|---|

| Composition | Ethylene and propylene | Ethylene, propylene, and a diene component |

| Crosslinking | Limited vulcanization options | Enhanced sulfur vulcanization due to diene |

| Weather Resistance | Good resistance | Excellent resistance to ozone, UV, and weathering |

| Heat Resistance | Up to 130degC continuous use | Up to 150degC continuous use |

| Cost | Lower cost | Higher cost due to diene addition |

| Applications | General seals, hoses, insulation | Automotive weather seals, roofing, electrical insulation |

| Flexibility | Good at low temperatures | Superior flexibility at low temperatures |

Introduction to EPM and EPDM

Enterprise Performance Management (EPM) streamlines strategic planning, budgeting, forecasting, and financial reporting to enhance organizational decision-making and efficiency. Engineering Product Data Management (EPDM) focuses on managing design data, version control, and collaboration in product development cycles, primarily used by engineering teams. Both systems improve data accuracy and process control but serve distinct business functions within an enterprise.

Chemical Structure Differences

EPM (ethylene propylene monomer) is an elastomer composed mainly of ethylene and propylene repeating units with a saturated backbone resulting in high chemical stability and resistance to oxidation. EPDM (ethylene propylene diene monomer) includes a third diene component, such as ethylidene norbornene, allowing for vulcanization through sulfur cross-linking, which enhances elasticity and heat resistance. The presence of the diene in EPDM introduces unsaturation sites, distinguishing its chemical structure from the fully saturated EPM and enabling different curing and performance properties.

Key Physical Properties

EPM (Ethylene Propylene Monomer) exhibits excellent resistance to heat, oxidation, and weathering, with a typical tensile strength ranging from 5 to 8 MPa and elongation at break up to 400%. EPDM (Ethylene Propylene Diene Monomer) enhances these properties by incorporating a diene component, offering improved vulcanization and superior resistance to ozone, UV rays, and aging, along with tensile strength ranging from 7 to 10 MPa and elongation at break between 300% and 500%. Both polymers maintain flexibility at low temperatures, but EPDM typically provides better mechanical performance and durability in harsh environmental conditions due to its enhanced cross-linking capabilities.

Resistance to Weathering and Ozone

EPM (Ethylene Propylene Monomer) and EPDM (Ethylene Propylene Diene Monomer) both exhibit strong resistance to weathering and ozone, with EPDM generally outperforming EPM due to its enhanced diene content that improves vulcanization and durability. EPDM's superior resistance ensures longer lifespan in outdoor applications exposed to harsh environmental conditions such as UV rays, ozone, and temperature extremes. When selecting a material for weather-resistant sealing or roofing, your choice of EPDM can provide better protection against degradation caused by prolonged ozone exposure.

Temperature Tolerance Comparison

EPDM rubber offers superior temperature tolerance, typically withstanding continuous temperatures ranging from -40degC to 150degC, making it ideal for high-heat applications. EPM rubber usually endures temperatures from -50degC to 120degC, with a slightly lower upper limit compared to EPDM. The enhanced heat resistance of EPDM is due to its terpolymer composition, which includes vinyl acetate, improving its thermal stability.

Applications in Industry

EPM (Enterprise Performance Management) primarily supports financial planning, budgeting, and forecasting in industries such as manufacturing and finance, enhancing decision-making and operational efficiency. EPDM (Enterprise Product Data Management) manages complex product data and engineering processes in industries like automotive, aerospace, and construction, improving collaboration and version control. Your choice between EPM and EPDM depends on whether your organization prioritizes financial performance optimization or product lifecycle management.

Advantages of EPM

EPM (Enterprise Performance Management) offers advantages such as real-time data integration, enabling businesses to make faster, data-driven decisions that improve financial and operational performance. Its advanced analytics and predictive modeling tools provide deeper insights into organizational performance, fostering strategic planning and risk management. EPM also enhances collaboration across departments by centralizing performance metrics and aligning goals with corporate objectives.

Benefits of EPDM

EPDM (Ethylene Propylene Diene Monomer) offers superior weather resistance, UV stability, and excellent flexibility compared to EPM (Ethylene Propylene Monomer), making it ideal for outdoor applications such as roofing and automotive seals. Its exceptional resistance to heat, ozone, and aging ensures long-lasting durability and reduced maintenance costs. Choosing EPDM for your projects enhances performance and reliability in harsh environmental conditions.

Cost and Availability

EPM (Enterprise Performance Management) solutions generally incur higher costs due to their advanced analytics, planning, and reporting capabilities, often requiring significant initial investment and ongoing licensing fees. EPDM (Enterprise Product Data Management) systems tend to be more affordable with scalable options and broader availability through various vendors catering to diverse industries. Availability for EPM platforms is typically tied to specialized providers, while EPDM solutions are widely accessible across multiple software markets, offering more flexible deployment models.

Choosing Between EPM and EPDM

Choosing between Enterprise Performance Management (EPM) and Enterprise Product Data Management (EPDM) depends on organizational goals and needs; EPM focuses on financial planning, budgeting, and analytics to enhance business performance, while EPDM centers on managing product data and engineering processes to streamline product development. Companies aiming to optimize financial workflows and strategic decision-making benefit from EPM, whereas those seeking improved product lifecycle management, version control, and collaboration prefer EPDM solutions. Evaluating specific requirements such as financial consolidation or engineering data management helps determine the appropriate system to implement for operational efficiency.

EPM vs EPDM Infographic

libmatt.com

libmatt.com