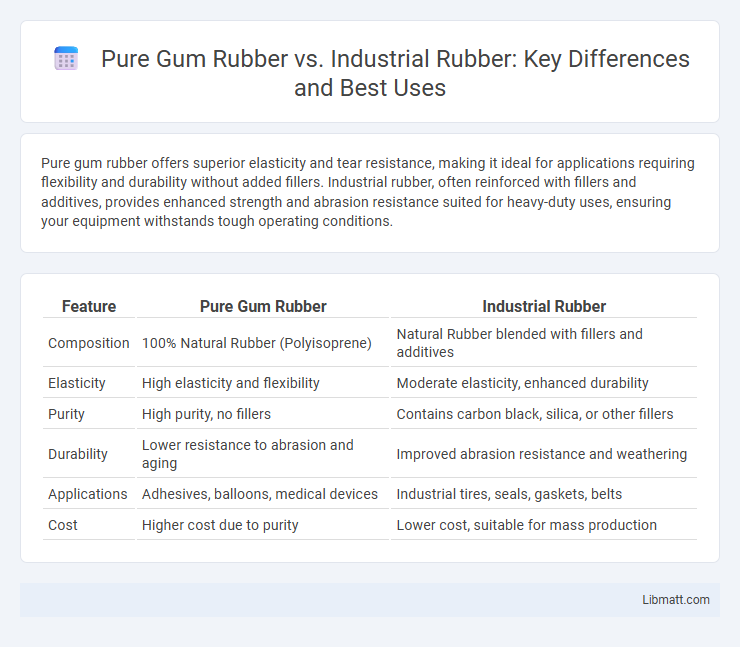

Pure gum rubber offers superior elasticity and tear resistance, making it ideal for applications requiring flexibility and durability without added fillers. Industrial rubber, often reinforced with fillers and additives, provides enhanced strength and abrasion resistance suited for heavy-duty uses, ensuring your equipment withstands tough operating conditions.

Table of Comparison

| Feature | Pure Gum Rubber | Industrial Rubber |

|---|---|---|

| Composition | 100% Natural Rubber (Polyisoprene) | Natural Rubber blended with fillers and additives |

| Elasticity | High elasticity and flexibility | Moderate elasticity, enhanced durability |

| Purity | High purity, no fillers | Contains carbon black, silica, or other fillers |

| Durability | Lower resistance to abrasion and aging | Improved abrasion resistance and weathering |

| Applications | Adhesives, balloons, medical devices | Industrial tires, seals, gaskets, belts |

| Cost | Higher cost due to purity | Lower cost, suitable for mass production |

Introduction to Pure Gum Rubber and Industrial Rubber

Pure gum rubber is a natural, unvulcanized rubber known for its smooth texture, elasticity, and excellent tackiness, making it ideal for applications like adhesive products and chewing gum bases. Industrial rubber, often vulcanized or synthetic, offers enhanced durability, chemical resistance, and mechanical strength suited for heavy-duty uses such as seals, gaskets, and automotive parts. Your choice between these materials depends on whether you prioritize flexibility and natural properties or resilience and industrial performance.

Key Differences in Composition

Pure gum rubber is a natural elastomer composed primarily of natural latex without added fillers, making it soft, flexible, and tacky to the touch. Industrial rubber often contains synthetic polymers combined with various additives such as carbon black, plasticizers, and curing agents to enhance durability, chemical resistance, and performance under harsh conditions. Your choice between the two should consider the specific application requirements for elasticity, strength, and environmental resistance.

Physical Properties Comparison

Pure gum rubber exhibits superior elasticity, resilience, and tensile strength compared to industrial rubber, making it ideal for applications requiring high flexibility and durability. Industrial rubber often contains additives and fillers that enhance hardness, abrasion resistance, and chemical stability but may compromise its stretchability and softness. Understanding these physical property differences helps you choose the right rubber type for your specific performance needs and environmental conditions.

Common Applications of Pure Gum Rubber

Pure gum rubber is widely used in applications requiring excellent elasticity and abrasion resistance, such as automotive seals, medical devices, and consumer goods like gloves and footwear. Its natural composition ensures superior flexibility and durability in products exposed to frequent bending and stretching. Your manufacturing projects benefit from pure gum rubber's non-staining properties and excellent adhesion to fabrics and metals.

Typical Uses for Industrial Rubber

Industrial rubber is extensively utilized in manufacturing seals, gaskets, hoses, and vibration dampening components for automotive, aerospace, and construction industries. Its durability and resistance to chemicals, heat, and abrasion make it ideal for heavy-duty applications in machinery and industrial equipment. Unlike pure gum rubber, which is valued for flexibility and elasticity in consumer products, industrial rubber prioritizes strength and longevity under harsh conditions.

Durability and Performance Factors

Pure gum rubber offers superior elasticity and resilience, making it highly durable under constant flexing and abrasion without cracking. Industrial rubber, often compounded with fillers and additives, provides enhanced mechanical strength and chemical resistance tailored for heavy-duty applications. Performance factors such as tensile strength, tear resistance, and aging stability vary significantly, with pure gum rubber excelling in flexibility and industrial rubber optimized for tough environmental conditions.

Environmental Resistance and Chemical Compatibility

Pure gum rubber exhibits superior environmental resistance with excellent flexibility and resilience against ozone, UV, and weathering, making it ideal for applications requiring natural durability. Industrial rubber, often compounded with synthetic additives, offers enhanced chemical compatibility, resisting oils, fuels, acids, and alkalis better than pure gum rubber. Understanding your application's exposure conditions helps determine whether the natural elasticity of pure gum rubber or the chemical resistance of industrial rubber best suits your needs.

Cost Considerations and Availability

Pure gum rubber typically costs more than industrial rubber due to its superior natural elasticity and purity, making it a premium choice for applications requiring flexibility and resilience. Industrial rubber, available in a wide range of synthetic compounds, offers more cost-effective solutions with consistent performance for mass production and heavy-duty uses. Your decision between these materials should factor in budget constraints as well as the availability of specific rubber grades suited to your project's requirements.

Maintenance and Lifespan

Pure gum rubber offers superior elasticity and resilience, resulting in easier maintenance and a longer lifespan compared to industrial rubber, which tends to be more prone to cracking and wear under heavy use. Industrial rubber often requires frequent inspections and replacement due to its lower resistance to environmental factors like heat and chemicals. Choosing pure gum rubber ensures your products maintain optimal performance with reduced downtime and maintenance costs.

Choosing the Right Rubber for Your Application

Pure gum rubber offers superior elasticity and resilience, making it ideal for applications requiring high flexibility and durability, such as seals and automotive parts. Industrial rubber, often compounded with fillers and additives, provides enhanced hardness, abrasion resistance, and chemical stability, suited for heavy-duty machinery and construction uses. Selecting the right rubber depends on balancing the need for softness and stretchability in pure gum rubber against the toughness and longevity required in industrial rubber components.

Pure Gum Rubber vs Industrial Rubber Infographic

libmatt.com

libmatt.com