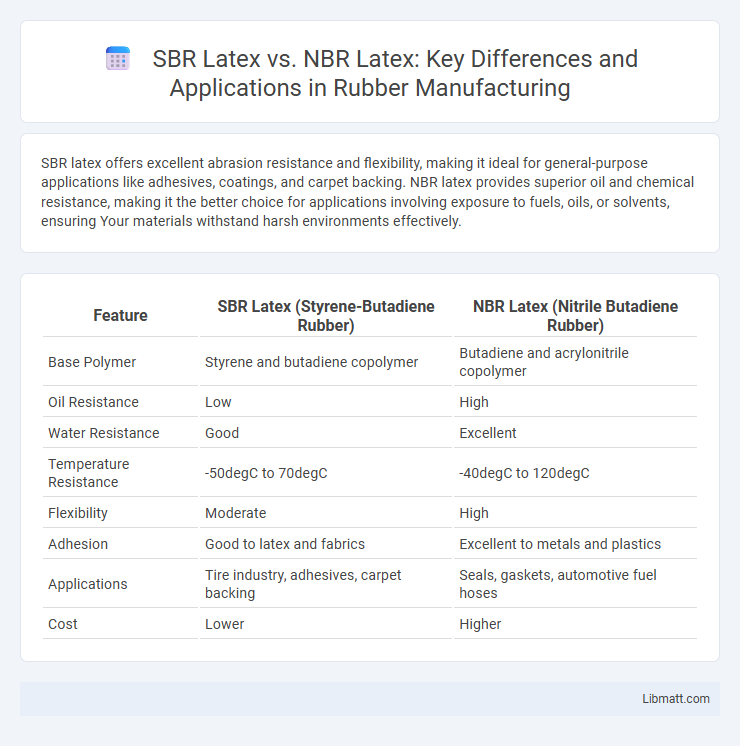

SBR latex offers excellent abrasion resistance and flexibility, making it ideal for general-purpose applications like adhesives, coatings, and carpet backing. NBR latex provides superior oil and chemical resistance, making it the better choice for applications involving exposure to fuels, oils, or solvents, ensuring Your materials withstand harsh environments effectively.

Table of Comparison

| Feature | SBR Latex (Styrene-Butadiene Rubber) | NBR Latex (Nitrile Butadiene Rubber) |

|---|---|---|

| Base Polymer | Styrene and butadiene copolymer | Butadiene and acrylonitrile copolymer |

| Oil Resistance | Low | High |

| Water Resistance | Good | Excellent |

| Temperature Resistance | -50degC to 70degC | -40degC to 120degC |

| Flexibility | Moderate | High |

| Adhesion | Good to latex and fabrics | Excellent to metals and plastics |

| Applications | Tire industry, adhesives, carpet backing | Seals, gaskets, automotive fuel hoses |

| Cost | Lower | Higher |

Introduction to SBR Latex and NBR Latex

SBR Latex, or Styrene-Butadiene Rubber latex, is a synthetic polymer widely used for its excellent abrasion resistance, aging stability, and cost-effectiveness in applications such as carpet backing, coatings, and adhesives. NBR Latex, or Nitrile Butadiene Rubber latex, is a synthetic rubber renowned for its superior oil, fuel, and chemical resistance, making it ideal for industrial gloves, seals, and protective coatings. Both SBR and NBR latex are emulsions utilized in various industries, but they differ significantly in chemical composition and performance properties suited to specific application needs.

Chemical Composition: SBR vs NBR Latex

SBR latex is composed primarily of styrene and butadiene monomers, providing excellent abrasion resistance and aging stability, while NBR latex consists of acrylonitrile and butadiene, offering superior oil, fuel, and chemical resistance due to the polar nitrile groups. The chemical composition of SBR emphasizes non-polar hydrocarbon chains enhancing mechanical resilience, whereas NBR's polar nitrile content improves compatibility with hydrocarbons and solvents. This fundamental difference in monomer selection results in distinct performance characteristics, with SBR preferred for general-purpose applications and NBR favored in environments requiring enhanced chemical resistance.

Key Properties and Performance Comparison

SBR Latex offers excellent abrasion resistance, good aging stability, and versatility for applications like carpet backing and coatings, while NBR Latex excels in oil resistance, tensile strength, and chemical stability, making it ideal for fuel-resistant gloves and seals. SBR has moderate resilience and water resistance, whereas NBR provides superior impermeability to oils and hydrocarbons. The choice between SBR and NBR Latex depends on specific performance requirements such as flexibility, durability, and exposure to chemicals or oils.

Applications of SBR Latex

SBR Latex is widely used in construction for concrete admixtures, offering enhanced durability, flexibility, and water resistance in flooring, adhesives, and coatings. It improves the bonding strength in tile adhesives, sealants, and cementitious compounds, making it ideal for industrial and residential projects. Compared to NBR Latex, which is favored in applications requiring oil and chemical resistance, SBR Latex excels in building materials and waterproofing solutions.

Applications of NBR Latex

NBR Latex is widely used in the production of disposable gloves, adhesives, and protective coatings due to its excellent resistance to oils, chemicals, and abrasion. Its superior elasticity and durability make it ideal for applications in automotive sealing systems, footwear, and medical devices. Compared to SBR Latex, NBR Latex provides enhanced performance in environments requiring chemical resistance and long-lasting flexibility.

Resistance to Chemicals and Oils

SBR latex exhibits moderate resistance to chemicals and oils, making it suitable for applications involving mild exposure to hydrocarbons and certain solvents. NBR latex offers superior chemical and oil resistance due to its nitrile butadiene composition, which performs well against petroleum-based fluids, fuels, and aggressive oils. The choice between SBR and NBR latex hinges on the level of chemical exposure, with NBR preferred for environments requiring enhanced oil resistance and durability.

Mechanical and Physical Strength Differences

SBR Latex exhibits higher tensile strength and better abrasion resistance compared to NBR Latex, making it suitable for applications requiring durability and wear resistance. NBR Latex offers superior oil and chemical resistance with good mechanical properties, but generally has lower elasticity and tensile strength than SBR Latex. The physical strength of SBR Latex excels in dynamic performance, while NBR Latex is preferred in environments involving exposure to fuels and oils.

Environmental Impact and Safety Considerations

SBR latex is derived primarily from styrene and butadiene, exhibiting moderate environmental impact due to its synthetic nature and potential VOC emissions during production, while NBR latex, made from acrylonitrile and butadiene, poses concerns related to acrylonitrile toxicity and requires careful handling to minimize health risks. Both materials demand strict adherence to safety protocols during manufacturing and use, with SBR latex generally having slightly lower toxicity but similar environmental disposal challenges. Your choice between SBR and NBR latex should consider specific application requirements alongside their environmental footprints and occupational safety guidelines.

Cost Analysis: SBR Latex vs NBR Latex

SBR latex generally offers a more cost-effective solution compared to NBR latex due to its lower raw material and production expenses, making it suitable for budget-sensitive applications. While NBR latex provides superior oil, fuel, and chemical resistance, its higher manufacturing costs result in a premium price point. Businesses must weigh the trade-off between SBR's affordability and NBR's enhanced performance characteristics to optimize cost-efficiency in their specific industrial applications.

Choosing the Right Latex for Your Application

SBR latex offers excellent abrasion resistance and aging durability, making it ideal for applications in carpet backing and adhesives, while NBR latex provides superior oil, fuel, and chemical resistance, suitable for automotive seals and gloves. Selecting the appropriate latex depends on environmental exposure and mechanical stress: choose SBR for applications requiring flexibility and wear resistance in dry conditions, and NBR for enhanced protection against hydrocarbons and oils. Understanding the specific performance requirements ensures optimal application efficiency and product longevity.

SBR Latex vs NBR Latex Infographic

libmatt.com

libmatt.com