Compression set measures a material's ability to return to its original thickness after prolonged compressive stress, indicating permanent deformation. Resilience refers to the material's capacity to absorb energy and recover quickly from deformation, ensuring your product maintains flexibility and performance under repeated stress.

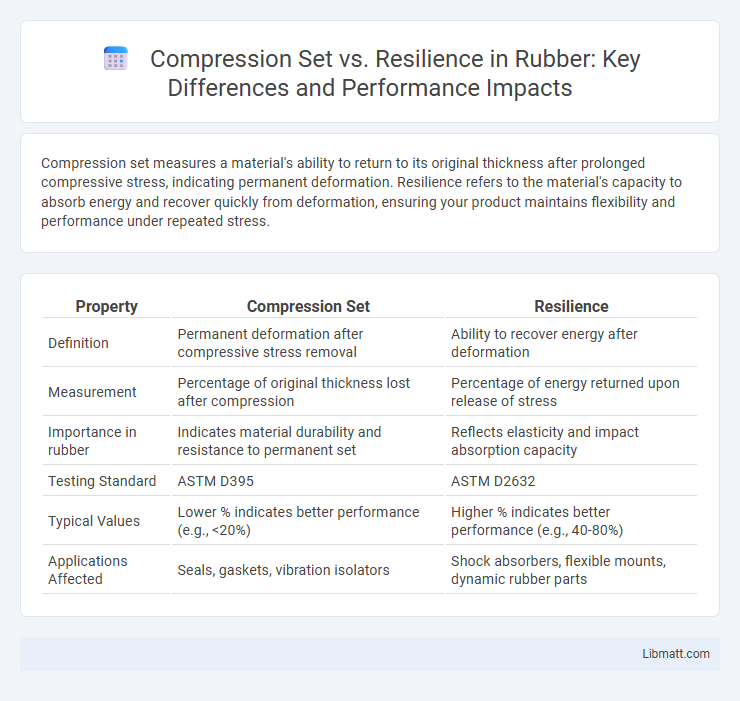

Table of Comparison

| Property | Compression Set | Resilience |

|---|---|---|

| Definition | Permanent deformation after compressive stress removal | Ability to recover energy after deformation |

| Measurement | Percentage of original thickness lost after compression | Percentage of energy returned upon release of stress |

| Importance in rubber | Indicates material durability and resistance to permanent set | Reflects elasticity and impact absorption capacity |

| Testing Standard | ASTM D395 | ASTM D2632 |

| Typical Values | Lower % indicates better performance (e.g., <20%) | Higher % indicates better performance (e.g., 40-80%) |

| Applications Affected | Seals, gaskets, vibration isolators | Shock absorbers, flexible mounts, dynamic rubber parts |

Introduction to Compression Set and Resilience

Compression set measures the permanent deformation of materials like rubber or foam after being compressed and released, indicating their ability to maintain original thickness. Resilience quantifies a material's capacity to absorb energy when deformed elastically and recover it upon unloading, reflecting its elasticity and energy return. Both properties are critical in designing products requiring durability and cushioning, such as seals, gaskets, and mattress foams.

Defining Compression Set

Compression set measures the permanent deformation of a material after it has been compressed and allowed to recover, indicating how much it fails to return to its original thickness. It is a critical parameter for materials like elastomers and foam, reflecting their ability to maintain shape under prolonged stress. In contrast, resilience refers to a material's capacity to absorb energy and recover its shape quickly after deformation, emphasizing immediate elastic recovery rather than permanent deformation.

Understanding Resilience in Materials

Resilience in materials measures their ability to absorb energy and return to their original shape after deformation, crucial for applications requiring durability and flexibility. Unlike compression set, which quantifies permanent deformation after compressive stress, resilience highlights the material's capacity to recover elastically. Understanding resilience helps you select materials that maintain performance under repeated stress without significant damage.

Key Differences Between Compression Set and Resilience

Compression set measures the permanent deformation of a material after it has been compressed and allowed to recover, indicating how well a material retains its shape under prolonged stress. Resilience refers to a material's ability to absorb energy and recover its original shape quickly after deformation, highlighting its elasticity and shock-absorbing capacity. Understanding the key differences between compression set and resilience helps you choose materials for applications requiring either long-term shape retention or rapid recovery from impact.

Factors Affecting Compression Set

Factors affecting compression set include temperature, load duration, and material composition, which influence the permanent deformation of elastomers after prolonged compression. High temperatures accelerate molecular relaxation, increasing the compression set, while longer load durations cause more significant material deformation. Your choice of elastomer with optimized resilience can minimize compression set, preserving cushioning and sealing performance.

Influences on Material Resilience

Material resilience is critically influenced by its compression set, where a lower compression set generally indicates superior ability to recover its original shape after deformation. Factors such as polymer type, cross-link density, temperature exposure, and aging significantly affect both compression set and resilience. Optimizing these parameters enhances the elastic recovery and durability of elastomeric materials in various industrial applications.

Importance in Material Selection

Compression set and resilience are critical factors in material selection, directly impacting the durability and performance of elastomers and polymers under repeated stress. A low compression set ensures your material maintains its shape and sealing ability after prolonged compression, while high resilience allows it to quickly recover its original form, crucial for dynamic applications. Prioritizing both properties leads to longer-lasting components and reduces maintenance costs in industries like automotive, aerospace, and manufacturing.

Common Testing Methods

Compression Set testing measures the permanent deformation of a material after prolonged compression, typically evaluated using ASTM D395 standards to assess elastomers' ability to return to original thickness. Resilience testing quantifies a material's ability to absorb and release energy, commonly conducted through the ASTM D2632 or ASTM D412 methods involving cyclic loading and recovery analysis. Your material selection for cushioning or sealing applications can be optimized by comparing both Compression Set and Resilience test results to ensure durability and performance under stress.

Industrial Applications and Considerations

Compression set measures the permanent deformation of materials like rubber seals after prolonged compression, impacting their ability to maintain an effective seal in industrial applications such as automotive gaskets and hydraulic systems. Resilience indicates a material's capacity to recover its original shape quickly after deformation, critical in environments requiring repetitive motion or vibration absorption, such as conveyor belts and engine mounts. Selecting materials with the appropriate balance of low compression set and high resilience ensures durability, leak prevention, and consistent performance under cyclical stress in manufacturing and heavy machinery sectors.

Choosing the Right Material for Your Needs

Compression set measures how well a material retains its original thickness after prolonged pressure, indicating its permanent deformation. Resilience reflects the material's ability to recover quickly from impact or stress, showing its elasticity and energy return. Understanding these properties helps you select the right material to balance durability and flexibility for your specific application.

Compression Set vs Resilience Infographic

libmatt.com

libmatt.com