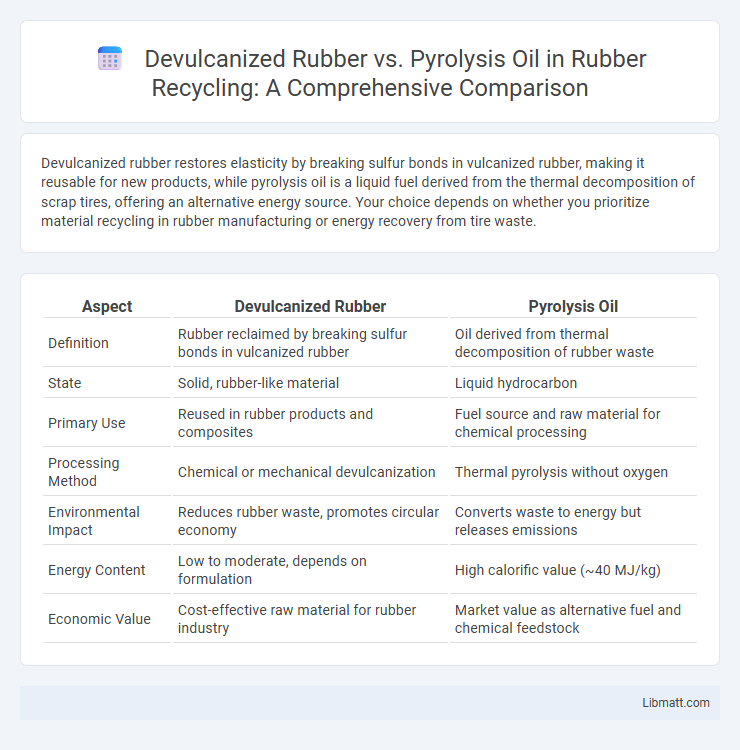

Devulcanized rubber restores elasticity by breaking sulfur bonds in vulcanized rubber, making it reusable for new products, while pyrolysis oil is a liquid fuel derived from the thermal decomposition of scrap tires, offering an alternative energy source. Your choice depends on whether you prioritize material recycling in rubber manufacturing or energy recovery from tire waste.

Table of Comparison

| Aspect | Devulcanized Rubber | Pyrolysis Oil |

|---|---|---|

| Definition | Rubber reclaimed by breaking sulfur bonds in vulcanized rubber | Oil derived from thermal decomposition of rubber waste |

| State | Solid, rubber-like material | Liquid hydrocarbon |

| Primary Use | Reused in rubber products and composites | Fuel source and raw material for chemical processing |

| Processing Method | Chemical or mechanical devulcanization | Thermal pyrolysis without oxygen |

| Environmental Impact | Reduces rubber waste, promotes circular economy | Converts waste to energy but releases emissions |

| Energy Content | Low to moderate, depends on formulation | High calorific value (~40 MJ/kg) |

| Economic Value | Cost-effective raw material for rubber industry | Market value as alternative fuel and chemical feedstock |

Introduction to Devulcanized Rubber and Pyrolysis Oil

Devulcanized rubber is reclaimed rubber produced by reversing the vulcanization process, enabling the reuse of cross-linked rubber materials from tires and industrial products. Pyrolysis oil, also called bio-oil or tire oil, is a liquid byproduct derived from the thermal decomposition of waste tires and other organic materials through pyrolysis technology. Both Devulcanized rubber and Pyrolysis oil present sustainable approaches to rubber waste management, providing raw materials for industries such as manufacturing, fuel production, and chemical synthesis.

Definition and Production Processes

Devulcanized rubber is reclaimed rubber obtained by breaking the sulfur cross-links in vulcanized rubber through chemical, thermal, or mechanical processes, restoring its original plasticity for reuse. Pyrolysis oil, also known as bio-oil or synthetic crude, is produced by thermally decomposing rubber waste at high temperatures in an oxygen-free environment, resulting in a liquid hydrocarbon mixture. Your choice between these materials depends on the desired application, with devulcanized rubber suitable for rubber manufacturing and pyrolysis oil primarily used as an alternative fuel or chemical feedstock.

Raw Materials and Sources

Devulcanized rubber primarily originates from reclaimed scrap tires and other vulcanized rubber products, undergoing chemical or mechanical processes to break down sulfur cross-links for reuse. Pyrolysis oil is derived from the thermal decomposition of waste plastics, tires, and biomass through pyrolysis reactors, yielding a liquid fuel rich in hydrocarbons. Your choice between these materials depends on the availability of specific waste streams and the desired end-use applications.

Chemical and Physical Properties

Devulcanized rubber retains much of the original polymer chains with restored elasticity and flexibility, characterized by lower cross-link density and improved molecular mobility, while pyrolysis oil consists of a complex mixture of hydrocarbons including aromatics, alkanes, and olefins with variable viscosity and calorific value depending on feedstock and process conditions. The chemical structure of devulcanized rubber allows for enhanced reprocessing and blending in rubber products, whereas pyrolysis oil's composition makes it suitable as a combustible fuel or chemical feedstock but requires refining for consistent quality. Your choice between these materials depends on whether flexibility and rubber-like properties or energy content and liquid fuel characteristics are prioritized.

Environmental Impact Comparison

Devulcanized rubber significantly reduces landfill waste by enabling the recycling of used tires into new rubber products, minimizing the need for virgin materials and lowering carbon emissions. Pyrolysis oil, derived from the thermal decomposition of rubber waste, can substitute fossil fuels but may release harmful pollutants if not properly refined, posing environmental risks. Your choice between these technologies influences waste management sustainability and air quality outcomes in the rubber recycling industry.

Industrial Applications and Uses

Devulcanized rubber is widely used in manufacturing new rubber products such as tires, seals, and conveyor belts due to its restored elasticity and durability. Pyrolysis oil serves as a valuable alternative fuel and chemical feedstock in industries like power generation and refining, providing a sustainable energy source. Your choice between these materials depends on the specific industrial application, whether it's recycling rubber into new products or generating energy from waste materials.

Economic Advantages and Limitations

Devulcanized rubber offers significant economic advantages by enabling the reuse of rubber materials in manufacturing, reducing raw material costs and minimizing waste disposal expenses. Pyrolysis oil presents a valuable alternative energy source with the potential to lower fuel costs and generate revenue from waste tire processing, yet its market viability is limited by inconsistent quality and the need for refining. Understanding your project's scale and resource availability helps determine which option provides optimal economic benefits while balancing process limitations.

Market Trends and Demand Analysis

Devulcanized rubber is gaining traction in the circular economy due to its ability to restore the properties of used rubber, driving demand in tire manufacturing and automotive sectors. Pyrolysis oil, derived from the thermal decomposition of scrap tires, is expanding as a sustainable energy source with growing applications in power generation and fuel blending. Your strategic decisions should consider the increasing regulatory support and market preference for recycled materials, which are propelling both devulcanized rubber and pyrolysis oil markets globally.

Technological Innovations and Developments

Technological innovations in devulcanized rubber processing have enhanced the efficiency of sulfur bond breaking, resulting in higher-quality recycled rubber materials suitable for tire manufacturing and industrial applications. Developments in pyrolysis oil production focus on optimizing thermal decomposition processes to increase yield and improve the oil's composition for use as a sustainable fuel or chemical feedstock. Your choice between these technologies depends on whether you prioritize the recovery of reusable rubber polymers or the generation of versatile energy-rich liquids.

Future Prospects and Sustainability

Devulcanized rubber offers a circular solution by restoring vulcanized rubber to its original state, enabling reuse in new products and significantly reducing landfill waste. Pyrolysis oil provides an alternative fuel source by converting waste rubber into valuable hydrocarbons but involves energy-intensive processes with potential emissions concerns. Your choice between these technologies impacts long-term sustainability, as devulcanization promotes material recovery and reuse, while pyrolysis contributes to energy recovery with trade-offs in environmental footprint.

Devulcanized Rubber vs Pyrolysis Oil Infographic

libmatt.com

libmatt.com