Ethylene Propylene Rubber (EPR) and EPDM both offer excellent resistance to weathering, ozone, and heat, but EPDM typically includes a diene component that enhances its vulcanization properties and flexibility. Your choice depends on specific application needs such as exposure conditions and mechanical performance, with EPDM often preferred for automotive and roofing sealants.

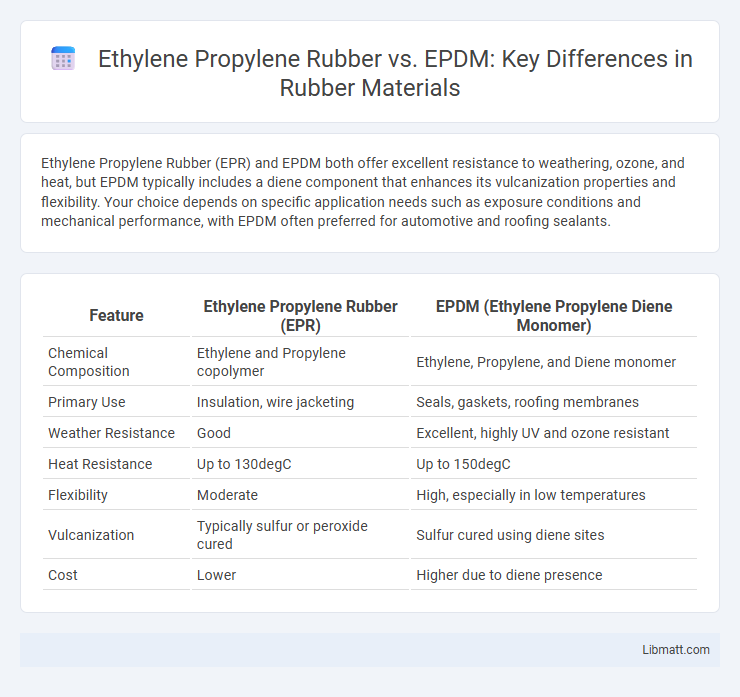

Table of Comparison

| Feature | Ethylene Propylene Rubber (EPR) | EPDM (Ethylene Propylene Diene Monomer) |

|---|---|---|

| Chemical Composition | Ethylene and Propylene copolymer | Ethylene, Propylene, and Diene monomer |

| Primary Use | Insulation, wire jacketing | Seals, gaskets, roofing membranes |

| Weather Resistance | Good | Excellent, highly UV and ozone resistant |

| Heat Resistance | Up to 130degC | Up to 150degC |

| Flexibility | Moderate | High, especially in low temperatures |

| Vulcanization | Typically sulfur or peroxide cured | Sulfur cured using diene sites |

| Cost | Lower | Higher due to diene presence |

Introduction to Ethylene Propylene Rubber and EPDM

Ethylene Propylene Rubber (EPR) is a synthetic elastomer known for its excellent resistance to heat, oxidation, and weathering, making it ideal for automotive and industrial applications. EPDM (Ethylene Propylene Diene Monomer) is a specific type of EPR that incorporates a diene component, enhancing its vulcanization properties and providing superior flexibility and durability under extreme weather conditions. Understanding the differences between EPR and EPDM can help you choose the best material for sealing, roofing, or insulation projects requiring long-term performance and resilience.

Chemical Composition and Structure

Ethylene Propylene Rubber (EPR) and EPDM (Ethylene Propylene Diene Monomer) differ primarily in their chemical composition and molecular structure. EPR is a copolymer of ethylene and propylene, providing excellent electrical insulation and chemical resistance but lacking unsaturation in its backbone. EPDM includes a diene monomer, introducing double bonds that enhance vulcanization and improve weather and ozone resistance, making your choice dependent on the required durability and application environment.

Manufacturing Processes Compared

Ethylene Propylene Rubber (EPR) and EPDM (Ethylene Propylene Diene Monomer) differ primarily in their manufacturing processes, where EPR is produced through a copolymerization of ethylene and propylene using a Ziegler-Natta catalyst. EPDM manufacturing involves the incorporation of a diene monomer, such as ethylidene norbornene, allowing for vulcanization through sulfur cross-linking, which enhances its elasticity and weather resistance. The choice of catalyst and the inclusion of a diene monomer result in distinct molecular structures, impacting the physical properties and applications of EPR and EPDM.

Key Physical and Mechanical Properties

Ethylene Propylene Rubber (EPR) and Ethylene Propylene Diene Monomer (EPDM) differ primarily in chemical composition, impacting their physical and mechanical properties. EPR offers excellent electrical insulation and flexibility, with high resistance to heat, ozone, and weathering, typically exhibiting tensile strength around 7-15 MPa and elongation at break over 300%. EPDM enhances these properties by incorporating diene monomers, improving vulcanization and elasticity, leading to superior abrasion resistance, tensile strength up to 20 MPa, and excellent compression set performance, making it ideal for sealing and automotive applications.

Weather and Ozone Resistance

Ethylene Propylene Rubber (EPR) and Ethylene Propylene Diene Monomer (EPDM) both offer excellent resistance to weathering and ozone degradation, making them ideal for outdoor applications. EPDM contains a diene component that enhances crosslinking, providing superior durability against UV radiation and ozone compared to standard EPR. The improved oxidation resistance of EPDM ensures a longer lifespan in harsh environmental conditions such as extreme temperatures and prolonged sunlight exposure.

Applications in Various Industries

Ethylene Propylene Rubber and EPDM are widely used in automotive, construction, and electrical industries due to their excellent resistance to heat, ozone, and weathering. EPDM's superior elasticity and durability make it ideal for roofing membranes, seals, and gaskets, whereas Ethylene Propylene Rubber is preferred in automotive hoses and electrical insulation because of its insulating properties. Both materials' versatility enables their integration into industrial applications that demand long-term performance in harsh environments.

Performance in Extreme Temperatures

Ethylene Propylene Rubber (EPR) and EPDM both excel in resisting extreme temperatures, but EPDM offers superior performance in a wider temperature range, typically from -50degC to 150degC, making it more suitable for outdoor and automotive applications exposed to harsh weather conditions. EPR generally performs well between -40degC and 130degC, providing good flexibility and durability in cold and moderately hot environments. Your choice between EPR and EPDM should consider the specific temperature extremes and environmental factors your application will face to ensure optimal material longevity and performance.

Durability and Longevity

Ethylene Propylene Rubber (EPR) and EPDM are both synthetic elastomers known for their excellent durability and longevity, with EPDM typically exhibiting superior resistance to weathering, ozone, and UV exposure. EPDM's enhanced ability to withstand extreme temperatures and environmental conditions makes it ideal for outdoor applications, extending the lifespan of roofing materials, seals, and gaskets. Your choice of rubber depends on the specific durability requirements, with EPDM often preferred for long-term reliability in harsh environments.

Cost Considerations

Ethylene Propylene Rubber (EPR) typically offers a lower initial cost compared to EPDM due to its simpler manufacturing process and raw material availability. EPDM, known for superior weathering, ozone resistance, and durability, may incur higher upfront costs but often delivers better long-term value by reducing maintenance and replacement expenses. Evaluating your project's performance requirements and lifecycle expectations will help determine the most cost-effective choice between EPR and EPDM.

Choosing the Right Material: Ethylene Propylene Rubber vs EPDM

Ethylene Propylene Rubber (EPR) and EPDM (Ethylene Propylene Diene Monomer) share similar chemical bases but differ in key properties like ozone resistance and flexibility. EPDM incorporates a diene monomer, enhancing its heat, weather, and ozone resistance, making it ideal for outdoor applications, while EPR offers superior electrical insulation and chemical resistance for specialized industrial uses. Your choice depends on the specific environmental exposure and mechanical requirements of your project, with EPDM favored for dynamic weather conditions and EPR suited for demanding electrical insulation.

Ethylene Propylene Rubber vs EPDM Infographic

libmatt.com

libmatt.com