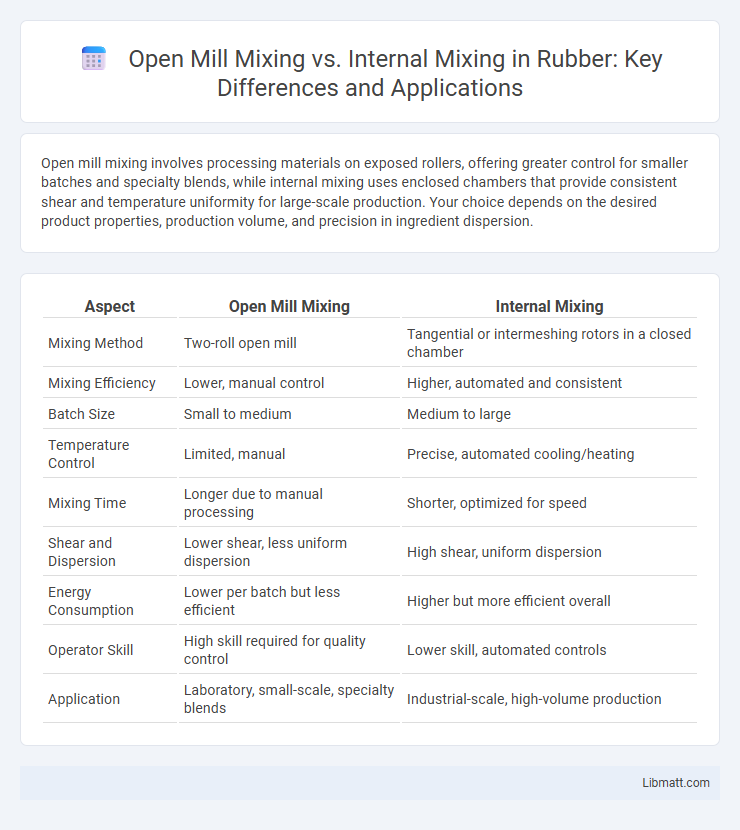

Open mill mixing involves processing materials on exposed rollers, offering greater control for smaller batches and specialty blends, while internal mixing uses enclosed chambers that provide consistent shear and temperature uniformity for large-scale production. Your choice depends on the desired product properties, production volume, and precision in ingredient dispersion.

Table of Comparison

| Aspect | Open Mill Mixing | Internal Mixing |

|---|---|---|

| Mixing Method | Two-roll open mill | Tangential or intermeshing rotors in a closed chamber |

| Mixing Efficiency | Lower, manual control | Higher, automated and consistent |

| Batch Size | Small to medium | Medium to large |

| Temperature Control | Limited, manual | Precise, automated cooling/heating |

| Mixing Time | Longer due to manual processing | Shorter, optimized for speed |

| Shear and Dispersion | Lower shear, less uniform dispersion | High shear, uniform dispersion |

| Energy Consumption | Lower per batch but less efficient | Higher but more efficient overall |

| Operator Skill | High skill required for quality control | Lower skill, automated controls |

| Application | Laboratory, small-scale, specialty blends | Industrial-scale, high-volume production |

Introduction to Rubber Mixing Methods

Open mill mixing uses two rotating steel rolls to blend rubber compounds, offering hands-on control and adaptability for small to medium batches. Internal mixing employs a closed chamber with rotating rotors, enabling high shear and temperature control for consistent compound quality in large-scale production. Both methods are essential in rubber processing, chosen based on desired compound properties and manufacturing scale.

Overview of Open Mill Mixing

Open mill mixing involves using two horizontally opposed, counter-rotating rolls to blend rubber compounds with fillers and additives, allowing for precise control over temperature and shear. This method offers greater flexibility for small batch production and effective dispersion of ingredients, making it ideal for custom formulations. Compared to internal mixing, open mill mixing provides better visibility of the material throughout the process, facilitating adjustments in real-time.

Fundamental Process of Internal Mixing

The fundamental process of internal mixing involves the use of closely intermeshing rotors within a sealed chamber to apply high shear and pressure on rubber compounds, ensuring thorough dispersion of fillers and additives. This method achieves superior homogenization by controlling temperature and mixing intensity precisely, which is critical for consistent material properties. Internal mixing offers You enhanced control over compound quality compared to open mill mixing, where the rubber is spread and mixed on large rotating rolls with less intensive shear forces.

Key Equipment Differences

Open mill mixing uses two horizontally mounted rolls that rotate in opposite directions to blend materials, allowing for easy adjustment of roll gap and direct observation of the process. Internal mixing employs a closed chamber with rotors that shear and mix materials under controlled temperature and pressure, providing consistent dispersion and higher energy input. Open mills are ideal for small batches and sheet production, while internal mixers excel in large-scale, homogeneous compound preparation.

Comparative Mixing Efficiency

Internal mixers provide superior mixing efficiency due to their enclosed environment and consistent shear forces, resulting in homogeneous compound blending. Open mill mixing, while less efficient, allows for greater control over temperature and smaller batch adjustments, but often leads to longer mixing times and variable dispersion quality. The enclosed design of internal mixers reduces contamination and energy loss, enhancing overall mixing speed and consistency compared to open mills.

Impact on Compound Uniformity

Open mill mixing offers greater flexibility in adjusting compound properties but may result in less uniform dispersion of fillers and additives due to manual control limitations. Internal mixing, utilizing controlled temperature, pressure, and mechanical shear within a closed chamber, enhances compound uniformity by ensuring consistent blending and improved filler distribution. Consequently, internal mixers are preferred for achieving high-quality, homogenous rubber compounds in industrial applications.

Energy Consumption and Cost Analysis

Open mill mixing generally consumes less energy than internal mixing due to simpler mechanical operation and lower torque requirements. However, internal mixing offers more precise compound uniformity, reducing material waste and ultimately lowering overall production costs. Your choice will depend on balancing upfront energy expenses against long-term cost efficiency and product quality.

Safety Considerations and Controls

Open mill mixing requires stringent safety measures due to exposed rotating rolls presenting pinch-point hazards, necessitating emergency stop controls, safety interlocks, and protective guards to prevent operator injury. Internal mixing machines offer enhanced safety through enclosed mixing chambers that limit operator access to moving parts, reducing risk of entanglement and contact with high-temperature components. Both systems demand regular maintenance of safety devices and employee training on lockout/tagout procedures and proper operation protocols to mitigate accident risks effectively.

Suitability for Different Rubber Compounds

Open mill mixing offers superior control when processing softer, low-viscosity rubber compounds such as natural rubber and silicone, enabling precise temperature and shear adjustments to optimize compound homogeneity. Internal mixing excels in handling high-viscosity, filled, or thermally sensitive rubber compounds like SBR, NBR, and EPDM by providing consistent and efficient dispersion through enclosed, high-shear environments that minimize contamination and oxygen exposure. Selecting between open mill and internal mixing depends on the rubber compound's viscosity, filler content, and thermal sensitivity to achieve ideal mixing uniformity and material properties.

Choosing the Optimal Mixing Technique

Choosing the optimal mixing technique depends on material type, batch size, and desired consistency; open mill mixing offers excellent control for small batches and precise dispersion of rubber compounds, while internal mixing excels in handling larger volumes with uniform shear and temperature distribution. Open mill mixing is ideal for specialized formulations requiring manual adjustment, whereas internal mixers provide efficient energy use and consistent compound quality for high-volume production. Evaluating factors such as material viscosity, cooling requirements, and production scale ensures selection of the most effective mixing method for superior rubber compound performance.

Open mill mixing vs Internal mixing Infographic

libmatt.com

libmatt.com