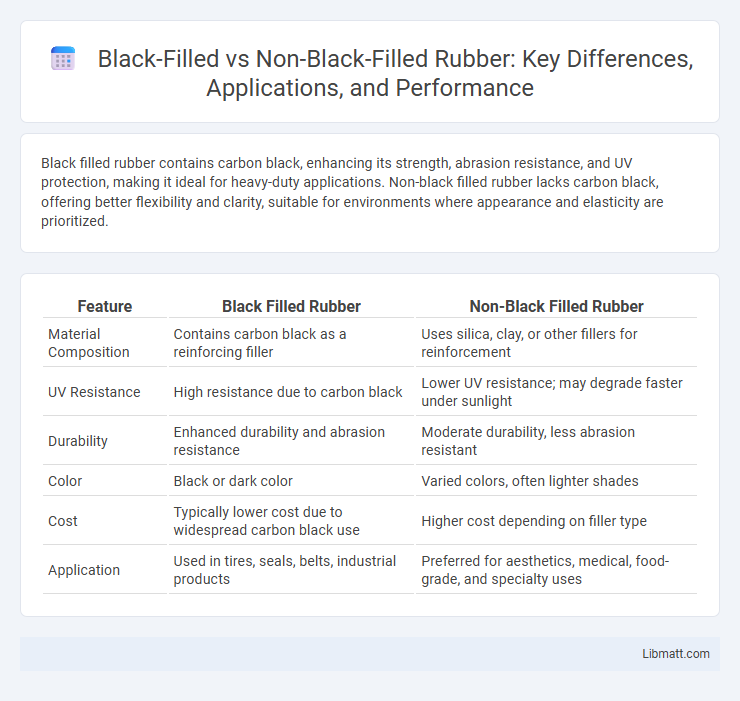

Black filled rubber contains carbon black, enhancing its strength, abrasion resistance, and UV protection, making it ideal for heavy-duty applications. Non-black filled rubber lacks carbon black, offering better flexibility and clarity, suitable for environments where appearance and elasticity are prioritized.

Table of Comparison

| Feature | Black Filled Rubber | Non-Black Filled Rubber |

|---|---|---|

| Material Composition | Contains carbon black as a reinforcing filler | Uses silica, clay, or other fillers for reinforcement |

| UV Resistance | High resistance due to carbon black | Lower UV resistance; may degrade faster under sunlight |

| Durability | Enhanced durability and abrasion resistance | Moderate durability, less abrasion resistant |

| Color | Black or dark color | Varied colors, often lighter shades |

| Cost | Typically lower cost due to widespread carbon black use | Higher cost depending on filler type |

| Application | Used in tires, seals, belts, industrial products | Preferred for aesthetics, medical, food-grade, and specialty uses |

Introduction to Rubber Fillers

Rubber fillers play a crucial role in enhancing the properties of rubber compounds; black filled rubber typically contains carbon black, which improves durability, tensile strength, and abrasion resistance. Non-black filled rubber uses alternative fillers like silica, clay, or calcium carbonate to achieve specific characteristics such as improved flexibility, reduced weight, or better heat resistance. Understanding the type of filler in your rubber product helps optimize performance for applications ranging from automotive parts to footwear.

What is Black Filled Rubber?

Black filled rubber contains carbon black as a reinforcing filler, enhancing its strength, durability, and abrasion resistance compared to non-black filled rubber. The carbon black particles improve the rubber's tensile properties while providing UV protection and increased lifespan in harsh environments. Non-black filled rubber typically uses alternative fillers, resulting in different mechanical characteristics and often less resistance to wear and environmental degradation.

Understanding Non-Black Filled Rubber

Non-black filled rubber uses fillers like silica or calcium carbonate instead of carbon black, resulting in lighter color compounds that improve aesthetic appeal and reduce heat build-up. These formulations offer enhanced abrasion resistance, lower rolling resistance, and better fuel efficiency compared to black filled rubber. Non-black filled rubber is preferred in applications requiring lighter coloration, improved durability, and environmental benefits.

Key Differences Between Black and Non-Black Filled Rubber

Black filled rubber features carbon black as a reinforcing filler, enhancing durability, abrasion resistance, and UV stability, making it ideal for outdoor and high-wear applications. Non-black filled rubber typically uses alternative fillers like silica or clay, resulting in lighter colors and improved flexibility, chemical resistance, and heat stability. Your choice depends on whether you prioritize strength and weather resistance or flexibility and chemical inertness.

Physical Properties Comparison

Black filled rubber contains carbon black, which significantly enhances its tensile strength, abrasion resistance, and UV stability compared to non-black filled rubber, which lacks these reinforcing fillers. Non-black filled rubber often exhibits better flexibility and resistance to ozone but generally has lower durability under mechanical stress. Your choice depends on whether you prioritize durability and strength (black filled) or flexibility and chemical resistance (non-black filled).

Performance and Durability

Black filled rubber contains carbon black, which significantly enhances its tensile strength, abrasion resistance, and UV protection, making it ideal for high-performance and durable applications. Non-black filled rubber, lacking carbon black, generally offers lower durability and is more prone to wear, making it less suitable for heavy-duty or outdoor environments. Your choice between these rubber types should consider the required performance level and expected environmental exposure.

Common Applications of Black Filled Rubber

Black filled rubber is widely used in automotive tires, industrial belts, and conveyor systems due to its enhanced durability and resistance to UV and ozone degradation. Non-black filled rubber, often employed in food-grade sealing, medical devices, and transparent tubing, prioritizes purity and chemical resistance over carbon black's reinforcing properties. Your choice depends on whether strength and abrasion resistance or chemical inertness and aesthetics are more critical for the application.

Typical Uses for Non-Black Filled Rubber

Non-black filled rubber is commonly used in applications requiring high transparency, flexibility, and chemical resistance, such as food processing equipment seals, medical devices, and optical components. Unlike black filled rubber, which contains carbon black for UV protection and strength, non-black filled rubber maintains clarity and reduces contamination risks. Typical materials include silicone, fluorosilicone, and EPDM, which excel in environments demanding non-marking and low particle shedding properties.

Cost and Manufacturing Considerations

Black filled rubber typically contains carbon black, which enhances durability and UV resistance while increasing material costs due to added processing complexity. Non-black filled rubber uses alternative fillers like silica or clay, often lowering expenses and simplifying manufacturing but may compromise some mechanical properties. Your choice depends on balancing cost efficiency with performance requirements in production.

Selecting the Right Rubber for Your Needs

Black filled rubber contains carbon black, enhancing durability, abrasion resistance, and UV protection, making it ideal for outdoor and heavy-duty applications. Non-black filled rubber, often colorless or white, offers better resistance to ozone, chemicals, and medical-grade compliance, suitable for sensitive or indoor environments. Your choice depends on application requirements, balancing toughness with chemical and environmental resistance.

Black filled vs Non-black filled rubber Infographic

libmatt.com

libmatt.com