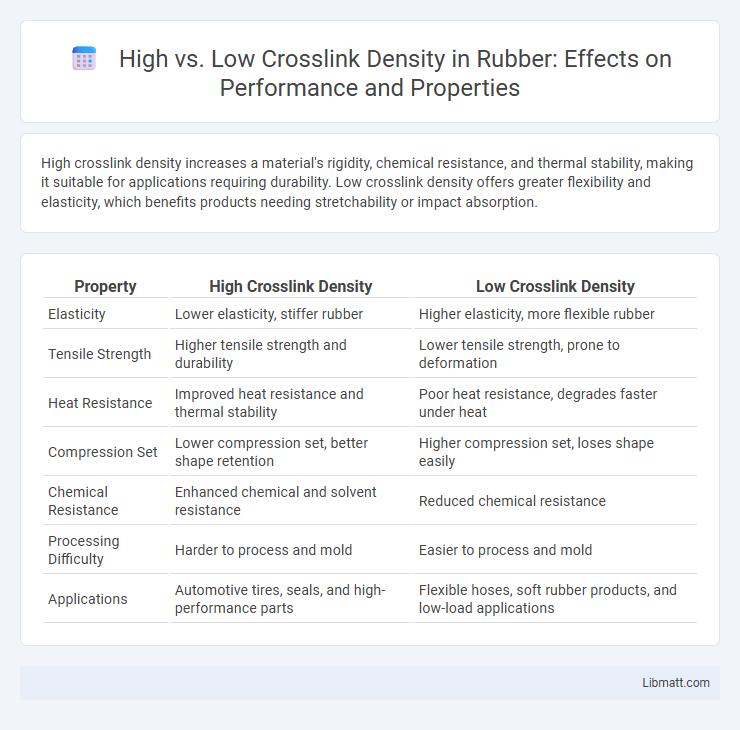

High crosslink density increases a material's rigidity, chemical resistance, and thermal stability, making it suitable for applications requiring durability. Low crosslink density offers greater flexibility and elasticity, which benefits products needing stretchability or impact absorption.

Table of Comparison

| Property | High Crosslink Density | Low Crosslink Density |

|---|---|---|

| Elasticity | Lower elasticity, stiffer rubber | Higher elasticity, more flexible rubber |

| Tensile Strength | Higher tensile strength and durability | Lower tensile strength, prone to deformation |

| Heat Resistance | Improved heat resistance and thermal stability | Poor heat resistance, degrades faster under heat |

| Compression Set | Lower compression set, better shape retention | Higher compression set, loses shape easily |

| Chemical Resistance | Enhanced chemical and solvent resistance | Reduced chemical resistance |

| Processing Difficulty | Harder to process and mold | Easier to process and mold |

| Applications | Automotive tires, seals, and high-performance parts | Flexible hoses, soft rubber products, and low-load applications |

Understanding Crosslink Density

Crosslink density refers to the number of crosslinks per unit volume in a polymer network, significantly impacting its mechanical and thermal properties. High crosslink density typically results in increased rigidity, tensile strength, and resistance to chemical solvents, while low crosslink density offers more flexibility and elasticity but reduced structural integrity. Understanding the balance in crosslink density is essential for designing materials with targeted performance characteristics, such as durable rubber compounds or flexible elastomers.

Defining High vs Low Crosslink Density

High crosslink density in polymers means a greater number of chemical bonds linking polymer chains, resulting in enhanced mechanical strength, thermal stability, and rigidity. Low crosslink density indicates fewer crosslinks, leading to increased flexibility, elasticity, and lower glass transition temperature. The degree of crosslink density directly influences polymer properties such as swelling behavior, solvent resistance, and durability in various applications.

Chemical Structure and Bond Formation

High crosslink density results in a tightly interconnected polymer network formed by numerous covalent bonds between polymer chains, enhancing rigidity and thermal resistance. Low crosslink density features fewer chemical linkages, allowing greater chain mobility and flexibility due to fewer covalent crosslinks. This variation in bond formation directly influences the polymer's mechanical properties, chemical stability, and response to environmental factors.

Mechanical Properties Comparison

High crosslink density enhances mechanical properties by increasing material stiffness, tensile strength, and resistance to deformation. Low crosslink density results in more flexible, elastic materials with lower tensile strength and reduced durability under mechanical stress. Your material choice depends on whether rigidity or flexibility is prioritized for the application.

Thermal Stability Differences

High crosslink density in polymers significantly enhances thermal stability by restricting molecular motion and preventing chain mobility at elevated temperatures. Low crosslink density results in polymer networks that soften and degrade more rapidly under heat due to insufficient physical constraints between chains. Your material selection should consider these thermal stability differences to ensure performance under specific temperature conditions.

Effects on Material Flexibility

Crosslink density significantly influences material flexibility, where a high crosslink density results in a rigid and less flexible structure due to tightly bound polymer chains, restricting molecular motion. Low crosslink density allows greater flexibility and elasticity, as polymer chains can move more freely, enhancing your material's ability to deform under stress. Optimizing crosslink density is crucial for applications requiring specific mechanical properties, such as elastomers or rigid plastics.

Impact on Chemical Resistance

Higher crosslink density in polymers significantly enhances chemical resistance by creating a tightly bonded network that limits the penetration of harmful chemicals. Low crosslink density results in a more porous structure, making materials more susceptible to chemical degradation and swelling. Your choice of crosslink density directly affects the durability and lifespan of products exposed to aggressive chemical environments.

Influence on Durability and Lifespan

High crosslink density in polymers significantly enhances durability by improving resistance to chemical degradation, heat, and mechanical stress, resulting in a longer lifespan for materials exposed to harsh environments. Low crosslink density offers increased flexibility but reduces durability, making materials more prone to wear, deformation, and faster aging under stress. Your choice of crosslink density should align with application requirements balancing durability and flexibility to optimize performance and lifespan.

Common Applications of High and Low Crosslink Density

High crosslink density materials are commonly used in applications requiring superior mechanical strength, chemical resistance, and thermal stability, such as automotive parts, industrial seals, and high-performance elastomers. Low crosslink density materials are preferred in soft, flexible applications like medical devices, flexible tubing, and cushioning materials where elasticity and softness are essential. Your choice between high and low crosslink density directly impacts the durability and flexibility required for specific industrial or consumer product uses.

Selecting the Right Crosslink Density for Your Needs

Selecting the right crosslink density is crucial for tailoring material properties to your specific application. High crosslink density provides enhanced strength, chemical resistance, and thermal stability, ideal for demanding environments, while low crosslink density offers greater flexibility and impact absorption, suitable for applications requiring elasticity. Understanding these differences ensures optimal performance and longevity in your products.

Crosslink density: High vs Low Infographic

libmatt.com

libmatt.com