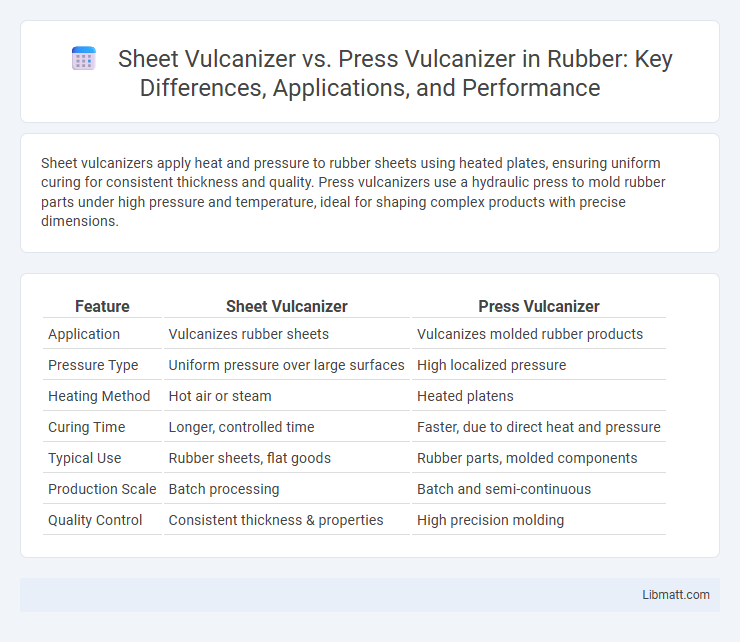

Sheet vulcanizers apply heat and pressure to rubber sheets using heated plates, ensuring uniform curing for consistent thickness and quality. Press vulcanizers use a hydraulic press to mold rubber parts under high pressure and temperature, ideal for shaping complex products with precise dimensions.

Table of Comparison

| Feature | Sheet Vulcanizer | Press Vulcanizer |

|---|---|---|

| Application | Vulcanizes rubber sheets | Vulcanizes molded rubber products |

| Pressure Type | Uniform pressure over large surfaces | High localized pressure |

| Heating Method | Hot air or steam | Heated platens |

| Curing Time | Longer, controlled time | Faster, due to direct heat and pressure |

| Typical Use | Rubber sheets, flat goods | Rubber parts, molded components |

| Production Scale | Batch processing | Batch and semi-continuous |

| Quality Control | Consistent thickness & properties | High precision molding |

Introduction to Vulcanization Methods

Sheet vulcanizers use heating plates to cure rubber sheets uniformly, ensuring consistent thickness and strong bonding for industrial applications. Press vulcanizers apply heat and pressure simultaneously, ideal for molding complex rubber parts with precise shapes and enhanced durability. Understanding these vulcanization methods helps you select the best process for efficient rubber product manufacturing.

What is a Sheet Vulcanizer?

A Sheet Vulcanizer is an industrial device designed to apply heat and pressure to rubber sheets, facilitating the vulcanization process that enhances the material's elasticity and strength. It uses heated platens to uniformly cure rubber sheets, ensuring consistent thickness and quality for manufacturing applications. The sheet vulcanizer is essential in industries like automotive and footwear, where precise rubber properties are critical.

Understanding Press Vulcanizer Technology

Press vulcanizer technology employs high pressure and heat to cure rubber sheets with precise control, ensuring uniform thickness and enhanced material strength. This method outperforms traditional sheet vulcanizers by reducing curing time and improving production efficiency, critical for industries requiring consistent rubber product quality. Understanding this technology helps you optimize vulcanization processes, ultimately boosting your manufacturing output and product durability.

Key Differences: Sheet vs. Press Vulcanizer

Sheet vulcanizers specialize in curing rubber sheets with uniform heat and pressure over large surface areas, ensuring consistent thickness and texture. Press vulcanizers use molds to shape and cure rubber, applying high pressure to form precise, three-dimensional parts. Your choice depends on whether you need flat sheets or molded components, influencing production efficiency and product application.

Material Compatibility and Applications

Sheet vulcanizers excel in processing delicate rubber sheets and thin materials like silicone and neoprene, offering precise temperature and pressure control suitable for laboratory settings and product prototyping. Press vulcanizers accommodate a wider range of materials, including thick rubber blocks, conveyor belts, and large molded parts, providing uniform heat and pressure ideal for industrial-scale production. The versatility of press vulcanizers makes them preferred for heavy-duty applications, while sheet vulcanizers are optimized for thin, flat rubber components requiring detailed finishing.

Performance and Efficiency Comparison

Sheet vulcanizers offer precise temperature control and uniform pressure distribution, resulting in consistent curing quality ideal for thin rubber sheets. Press vulcanizers provide higher pressure capabilities and faster cycle times, making them more efficient for thicker or larger rubber products. Your choice depends on balancing performance needs with production efficiency to optimize rubber curing processes.

Maintenance and Operational Requirements

Sheet vulcanizers require regular cleaning and calibration to maintain uniform heat distribution, while press vulcanizers demand routine inspection of hydraulic systems and molds to ensure consistent pressure application. Operationally, sheet vulcanizers involve manual loading and continuous monitoring, contrasting with press vulcanizers' automated cycles that reduce operator intervention. Both systems benefit from scheduled lubrication and timely replacement of wear parts to prevent downtime and maintain efficiency.

Cost Analysis: Sheet Vulcanizer vs Press Vulcanizer

Sheet vulcanizers generally incur lower initial investment costs compared to press vulcanizers, making them more suitable for small to medium-scale operations. Press vulcanizers, though more expensive upfront, offer higher production efficiency and consistency, which can lead to lower per-unit costs in high-volume manufacturing. When analyzing total cost of ownership, factors such as maintenance expenses, energy consumption, and cycle time must be considered, often tipping the balance in favor of press vulcanizers for large-scale, continuous production.

Industry Use Cases and Suitability

Sheet vulcanizers excel in industries requiring uniform rubber sheets like automotive gasket manufacturing and conveyor belts, offering precise temperature control ideal for thin, flat materials. Press vulcanizers suit heavy-duty applications such as tire retreading and large molded rubber components, providing robust pressure and heat for thicker, complex shapes. Their suitability hinges on product thickness and application complexity, with sheet vulcanizers optimal for thin sheets and press vulcanizers preferred for bulky or intricate rubber goods.

Choosing the Right Vulcanizer for Your Needs

Choosing the right vulcanizer depends on the specific requirements of your rubber products and production volume. Sheet vulcanizers excel in curing large rubber sheets uniformly, making them ideal for high-volume applications needing consistent thickness and quality. Press vulcanizers offer more precise control over pressure and temperature, suitable for smaller or complex-shaped rubber components where detailed finishes are critical for your project.

Sheet Vulcanizer vs Press Vulcanizer Infographic

libmatt.com

libmatt.com