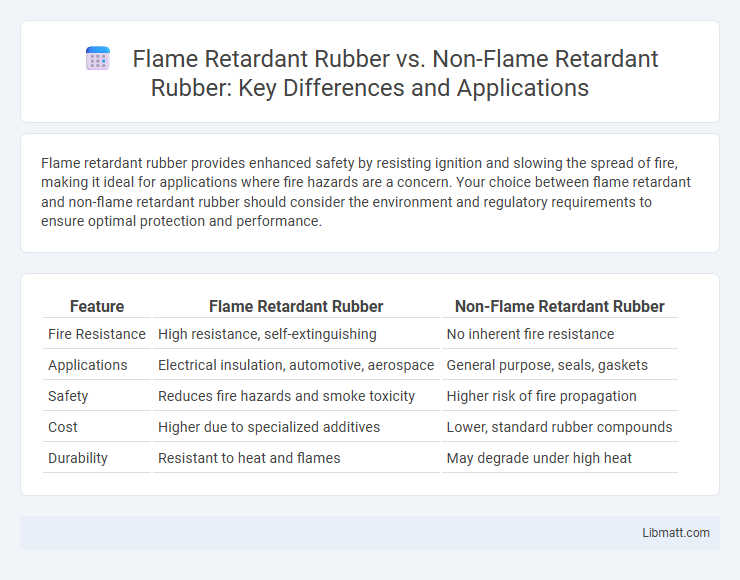

Flame retardant rubber provides enhanced safety by resisting ignition and slowing the spread of fire, making it ideal for applications where fire hazards are a concern. Your choice between flame retardant and non-flame retardant rubber should consider the environment and regulatory requirements to ensure optimal protection and performance.

Table of Comparison

| Feature | Flame Retardant Rubber | Non-Flame Retardant Rubber |

|---|---|---|

| Fire Resistance | High resistance, self-extinguishing | No inherent fire resistance |

| Applications | Electrical insulation, automotive, aerospace | General purpose, seals, gaskets |

| Safety | Reduces fire hazards and smoke toxicity | Higher risk of fire propagation |

| Cost | Higher due to specialized additives | Lower, standard rubber compounds |

| Durability | Resistant to heat and flames | May degrade under high heat |

Introduction to Flame Retardant and Non-Flame Retardant Rubber

Flame retardant rubber is engineered with chemical additives to resist ignition and slow the spread of fire, making it essential for safety-critical applications in automotive, electronics, and construction industries. Non-flame retardant rubber lacks these specialized compounds, offering flexibility and durability but posing increased fire risk in environments prone to high temperatures or sparks. Understanding the difference allows you to select the appropriate material for your specific safety and performance requirements.

Chemical Composition Differences

Flame retardant rubber incorporates specialized additives such as halogenated compounds, phosphorus-based chemicals, or metal hydroxides like aluminum hydroxide that disrupt combustion processes at the molecular level, enhancing fire resistance. Non-flame retardant rubber lacks these fire-inhibiting substances and typically consists of natural or synthetic polymers like neoprene or EPDM without chemical modifications targeting flame suppression. The presence or absence of these flame-retardant chemicals directly influences thermal degradation behavior, smoke production, and ignition resistance in rubber products.

Key Performance Properties

Flame retardant rubber exhibits superior resistance to ignition and slows the spread of fire, enhancing safety in critical applications. Non-flame retardant rubber lacks these properties, making it more susceptible to combustion and unsuitable for environments requiring high fire safety standards. Your choice between the two depends on the specific performance needs related to fire resistance and regulatory compliance.

Safety Standards and Regulations

Flame retardant rubber complies with stringent safety standards and regulations such as UL 94, ASTM E1354, and IEC 60695, ensuring reduced flammability, smoke emission, and toxicity during combustion. Non-flame retardant rubber lacks these certifications and poses higher risks of rapid fire spread and hazardous fume release in case of ignition. Regulatory bodies mandate the use of flame retardant rubber in electrical insulation, automotive, and construction applications to meet fire safety compliance and protect human health.

Applications in Different Industries

Flame retardant rubber is essential in electrical and automotive industries where fire safety standards are stringent, offering enhanced protection in wiring insulation, seals, and gaskets. In contrast, non-flame retardant rubber is commonly used in consumer goods, footwear, and general-purpose seals where fire resistance is not a critical requirement. The aerospace and construction sectors heavily rely on flame retardant rubber materials to meet regulatory compliance and reduce the risk of fire hazards in critical components.

Fire Resistance Testing Methods

Flame retardant rubber undergoes standardized fire resistance testing methods such as UL 94 vertical and horizontal burn tests, ASTM E1354 cone calorimeter tests, and ISO 5660 to evaluate ignition resistance, flame spread, and heat release rates. Non-flame retardant rubber often fails to meet these stringent criteria, exhibiting higher flammability and faster ignition times under identical testing conditions. Accurate fire resistance testing is critical for applications requiring enhanced safety, ensuring flame retardant rubber complies with regulatory standards for fire hazard mitigation.

Cost Comparison and Economic Impact

Flame retardant rubber generally comes at a higher initial cost compared to non-flame retardant varieties due to specialized chemical additives and manufacturing processes. Your investment in flame retardant rubber can lead to long-term economic benefits by reducing fire-related damages, insurance premiums, and compliance costs with safety regulations. Non-flame retardant rubber may offer immediate savings but can pose significant financial risks in fire-prone environments, impacting overall project budgets and liability exposure.

Environmental and Health Considerations

Flame retardant rubber contains chemical additives such as halogenated compounds or phosphates that can release toxic fumes and persistent organic pollutants during combustion, posing significant health risks and environmental challenges. Non-flame retardant rubber, while lacking these hazardous chemicals, may contribute to quicker spread of fire but releases fewer harmful substances upon burning. Selecting rubber materials requires balancing fire safety features with potential environmental toxicity and human exposure concerns related to chemical additives.

Lifespan and Durability

Flame retardant rubber typically has enhanced lifespan and durability due to the incorporation of additives that improve resistance to heat, fire, and oxidative degradation. Non-flame retardant rubber, while often more flexible and cost-effective, tends to degrade faster under high-temperature conditions and exposure to flames, leading to reduced longevity. The selection between these materials depends on the operational environment and safety requirements, with flame retardant rubber offering superior performance in fire-prone applications.

Choosing the Right Rubber for Your Needs

Flame retardant rubber offers enhanced safety by resisting ignition and slowing the spread of fire, making it essential for applications in electrical insulation, automotive components, and construction materials where fire hazards are significant. Non-flame retardant rubber provides flexibility and cost-effectiveness for general-purpose uses such as seals, gaskets, and footwear, where fire resistance is not a primary concern. Selecting the right rubber depends on balancing factors like fire safety requirements, environmental exposure, and regulatory compliance to ensure optimal performance and protection.

Flame retardant rubber vs Non-flame retardant Infographic

libmatt.com

libmatt.com