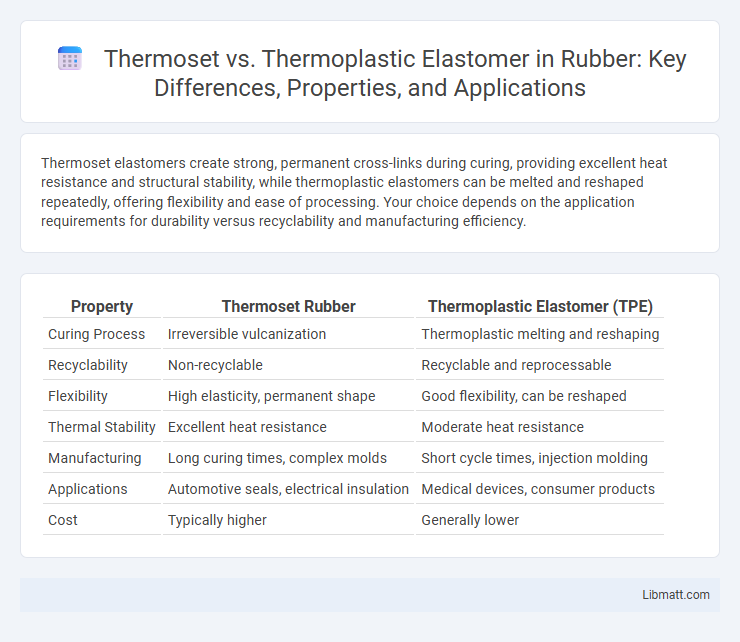

Thermoset elastomers create strong, permanent cross-links during curing, providing excellent heat resistance and structural stability, while thermoplastic elastomers can be melted and reshaped repeatedly, offering flexibility and ease of processing. Your choice depends on the application requirements for durability versus recyclability and manufacturing efficiency.

Table of Comparison

| Property | Thermoset Rubber | Thermoplastic Elastomer (TPE) |

|---|---|---|

| Curing Process | Irreversible vulcanization | Thermoplastic melting and reshaping |

| Recyclability | Non-recyclable | Recyclable and reprocessable |

| Flexibility | High elasticity, permanent shape | Good flexibility, can be reshaped |

| Thermal Stability | Excellent heat resistance | Moderate heat resistance |

| Manufacturing | Long curing times, complex molds | Short cycle times, injection molding |

| Applications | Automotive seals, electrical insulation | Medical devices, consumer products |

| Cost | Typically higher | Generally lower |

Introduction to Elastomers

Elastomers are polymers with viscoelasticity, known for their exceptional elasticity and ability to return to original shape after deformation. Thermoset elastomers form irreversible cross-linked networks during curing, providing superior thermal and chemical resistance but limited recyclability. Thermoplastic elastomers combine the elastic properties of rubbers with the processing advantages of thermoplastics, allowing melt reprocessing and enhanced versatility in applications.

Defining Thermoset Elastomers

Thermoset elastomers are polymers that undergo an irreversible curing process, creating a cross-linked molecular network that provides exceptional thermal stability and mechanical strength. Unlike thermoplastic elastomers, thermosets do not melt upon reheating, making them ideal for high-temperature applications such as automotive seals, electrical insulation, and heat-resistant gaskets. Their rigid, three-dimensional polymer structure ensures durability and resistance to deformation under stress and harsh environments.

Defining Thermoplastic Elastomers

Thermoplastic elastomers (TPEs) are polymeric materials combining the elastic properties of rubber with the processing advantages of thermoplastics, allowing them to be melted and reshaped multiple times. Unlike thermoset elastomers, which undergo irreversible curing, TPEs maintain flexibility and processability through physical cross-links rather than chemical bonds. Your selection between thermoset and TPE depends on the requirements for reusability, durability, and manufacturing efficiency.

Key Differences: Structure and Composition

Thermoset elastomers have a cross-linked molecular structure that forms a rigid, three-dimensional network upon curing, making them heat-resistant and permanently set. Thermoplastic elastomers (TPEs) consist of linear or branched polymers that can be melted and reshaped multiple times due to their thermoplastic nature, providing greater flexibility and recyclability. Your choice between these materials depends on the required durability, processing method, and end-use application.

Manufacturing Processes Compared

Thermoset elastomers undergo a curing process that involves irreversible chemical cross-linking, resulting in a rigid, heat-resistant material ideal for high-performance applications. Thermoplastic elastomers (TPEs) are processed through conventional melting and molding techniques, allowing easy reshaping and recycling without chemical change. Your choice between these materials influences manufacturing efficiency, tooling costs, and product lifecycle sustainability.

Performance Characteristics

Thermoset elastomers exhibit excellent heat resistance and superior dimensional stability due to their cross-linked molecular structure, making them ideal for high-temperature applications. Thermoplastic elastomers offer enhanced flexibility and recyclability with good chemical resistance, performing well in dynamic environments requiring repeated stress and deformation. The choice between thermoset and thermoplastic elastomers depends on specific requirements such as thermal endurance, elasticity, and manufacturing processes.

Mechanical Properties: Flexibility and Strength

Thermoset elastomers exhibit high mechanical strength and rigidity due to their cross-linked polymer chains, making them ideal for applications requiring structural integrity and heat resistance. Thermoplastic elastomers combine the flexibility of rubbers with the strength of thermoplastics, offering superior elasticity and impact resistance while allowing for easy processing and recycling. The balance between flexibility and strength in thermoplastic elastomers makes them suitable for dynamic applications where repeated deformation and recovery are essential.

Common Applications and Industries

Thermoset materials are widely used in automotive components, aerospace parts, and electrical insulators due to their high heat resistance and structural rigidity. Thermoplastic elastomers (TPEs) dominate industries like consumer goods, medical devices, and flexible packaging, offering excellent flexibility and recyclability. Your choice between thermoset and TPE depends on the application's requirement for durability, flexibility, and environmental considerations.

Environmental Impact and Recyclability

Thermoset plastics, once cured, form a rigid, cross-linked structure that makes them difficult to recycle and results in greater environmental impact due to their non-reprocessable nature. Thermoplastic elastomers (TPEs) can be melted and reshaped multiple times, significantly enhancing recyclability and reducing waste in manufacturing processes. Choosing TPEs for Your projects supports sustainability goals by enabling material reuse and lowering the carbon footprint associated with plastic waste.

Choosing the Right Elastomer: Factors to Consider

When choosing the right elastomer, consider the material's thermal stability, mechanical properties, and application environment. Thermoset elastomers offer superior heat resistance and structural integrity due to their cross-linked polymer networks, making them ideal for high-temperature or heavy-load applications. Your decision should also factor in flexibility, chemical resistance, and recyclability, where thermoplastic elastomers provide greater versatility and easier processing for products requiring repeated molding or recycling.

Thermoset vs Thermoplastic Elastomer Infographic

libmatt.com

libmatt.com