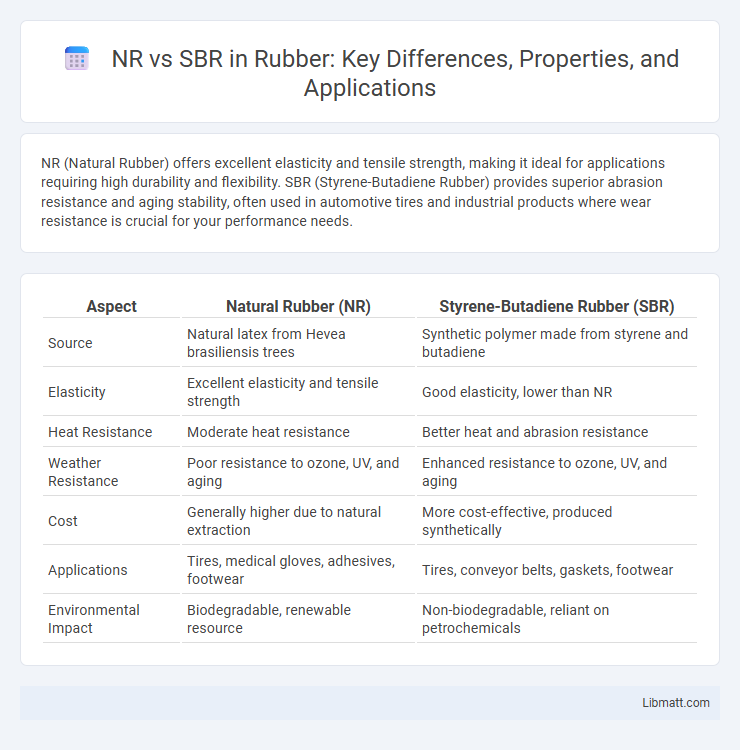

NR (Natural Rubber) offers excellent elasticity and tensile strength, making it ideal for applications requiring high durability and flexibility. SBR (Styrene-Butadiene Rubber) provides superior abrasion resistance and aging stability, often used in automotive tires and industrial products where wear resistance is crucial for your performance needs.

Table of Comparison

| Aspect | Natural Rubber (NR) | Styrene-Butadiene Rubber (SBR) |

|---|---|---|

| Source | Natural latex from Hevea brasiliensis trees | Synthetic polymer made from styrene and butadiene |

| Elasticity | Excellent elasticity and tensile strength | Good elasticity, lower than NR |

| Heat Resistance | Moderate heat resistance | Better heat and abrasion resistance |

| Weather Resistance | Poor resistance to ozone, UV, and aging | Enhanced resistance to ozone, UV, and aging |

| Cost | Generally higher due to natural extraction | More cost-effective, produced synthetically |

| Applications | Tires, medical gloves, adhesives, footwear | Tires, conveyor belts, gaskets, footwear |

| Environmental Impact | Biodegradable, renewable resource | Non-biodegradable, reliant on petrochemicals |

Introduction to NR and SBR

NR (Natural Rubber) is a polymer harvested from the latex of rubber trees, prized for its elasticity, resilience, and tear resistance in applications like automotive tires and industrial products. SBR (Styrene-Butadiene Rubber) is a synthetic rubber produced from styrene and butadiene monomers, known for its abrasion resistance and aging stability, commonly used in tire treads and footwear. Understanding the distinct properties of NR and SBR helps you select the right material for durability, flexibility, and performance needs.

Chemical Structure Comparison

Nitrile Rubber (NR) features a copolymer structure primarily composed of acrylonitrile and butadiene units, providing strong resistance to oils and solvents due to the polar nitrile groups. Styrene-Butadiene Rubber (SBR) consists of a random copolymer of styrene and butadiene, offering improved abrasion resistance and aging stability from the styrene content. The key chemical difference lies in NR's polar nitrile groups versus SBR's non-polar styrene units, influencing their respective chemical and physical properties.

Production Processes of NR and SBR

Natural rubber (NR) is produced through latex extraction from rubber trees, followed by coagulation, drying, and milling processes that preserve its natural polymer chains. Styrene-butadiene rubber (SBR) is synthesized via emulsion or solution polymerization of styrene and butadiene monomers, offering controlled composition and consistent quality. Understanding these distinct production processes helps you select the appropriate rubber type for specific industrial applications.

Physical Properties Analysis

Nitrile Rubber (NR) exhibits superior tensile strength and abrasion resistance compared to Styrene-Butadiene Rubber (SBR), making NR more suited for applications requiring durability under mechanical stress. SBR offers enhanced aging stability and resistance to heat, ozone, and weathering, attributed to its synthetic polymer structure. Both rubbers differ in elasticity and compression set, with NR providing higher elasticity while SBR maintains dimensional stability under prolonged stress.

Performance in Industrial Applications

NR (Natural Rubber) offers exceptional tensile strength and elasticity, making it ideal for dynamic industrial applications requiring flexibility and durability. SBR (Styrene-Butadiene Rubber) excels in abrasion resistance and heat stability, enhancing performance in harsh environments like conveyor belts and automotive components. Choosing the right material depends on your industrial application's specific needs for wear resistance and mechanical resilience.

Durability and Lifespan Differences

Natural Rubber (NR) offers excellent elasticity and flexibility but tends to degrade faster when exposed to ozone, UV light, and extreme weather conditions, limiting its durability in outdoor applications. Styrene-Butadiene Rubber (SBR) exhibits superior resistance to abrasion, aging, and environmental factors, resulting in a longer lifespan under harsh conditions. The longer durability of SBR makes it a preferred choice for automotive tires, conveyor belts, and industrial goods requiring extended wear resistance.

Environmental Impact and Sustainability

NR (Natural Rubber) is derived from rubber trees, making it a renewable resource with a lower carbon footprint and better biodegradability compared to SBR (Styrene-Butadiene Rubber), which is synthetic and petroleum-based. SBR production relies heavily on fossil fuels, contributing to higher greenhouse gas emissions and non-renewable resource depletion. Choosing NR supports environmental sustainability by promoting renewable materials and reducing long-term ecological impact.

Cost Comparison of NR vs SBR

Natural rubber (NR) generally incurs higher costs than styrene-butadiene rubber (SBR) due to its natural source, seasonal availability, and intensive harvesting process. SBR, a synthetic rubber derived from petroleum-based styrene and butadiene, offers a more consistent supply and cost-effective production, resulting in lower overall expenses for large-scale manufacturing. Your choice between NR and SBR will impact product pricing, especially in applications where cost-efficiency and supply stability are critical.

Advantages and Limitations

Noise Reduction (NR) improves audio clarity by minimizing background disturbances, enhancing listening experience in various environments. Sound Blending Reduction (SBR) enhances bitrate efficiency and bandwidth utilization for high-frequency audio components, providing better compression and audio fidelity. NR may struggle with non-stationary noises and can introduce artifacts, while SBR's effectiveness depends on encoding parameters and can result in reduced audio quality at very low bitrates.

Choosing Between NR and SBR

Choosing between NR and SBR depends on your specific application needs and performance requirements. NR (Natural Rubber) offers superior elasticity and better tear resistance, making it ideal for products requiring high durability and flexibility. SBR (Styrene-Butadiene Rubber) excels in abrasion resistance and cost-effectiveness, often preferred for tire treads and industrial uses where wear resistance and affordability are critical.

NR vs SBR Infographic

libmatt.com

libmatt.com