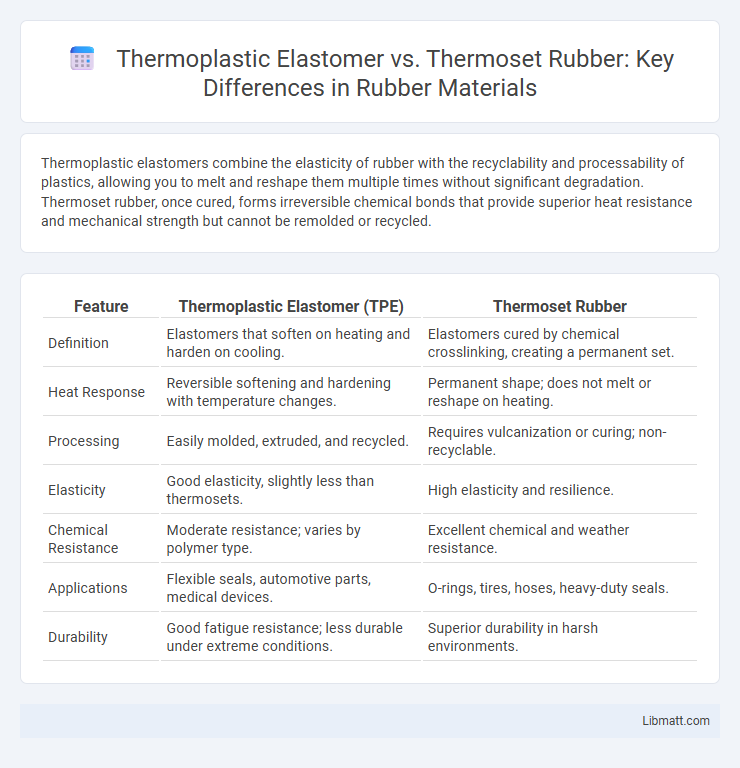

Thermoplastic elastomers combine the elasticity of rubber with the recyclability and processability of plastics, allowing you to melt and reshape them multiple times without significant degradation. Thermoset rubber, once cured, forms irreversible chemical bonds that provide superior heat resistance and mechanical strength but cannot be remolded or recycled.

Table of Comparison

| Feature | Thermoplastic Elastomer (TPE) | Thermoset Rubber |

|---|---|---|

| Definition | Elastomers that soften on heating and harden on cooling. | Elastomers cured by chemical crosslinking, creating a permanent set. |

| Heat Response | Reversible softening and hardening with temperature changes. | Permanent shape; does not melt or reshape on heating. |

| Processing | Easily molded, extruded, and recycled. | Requires vulcanization or curing; non-recyclable. |

| Elasticity | Good elasticity, slightly less than thermosets. | High elasticity and resilience. |

| Chemical Resistance | Moderate resistance; varies by polymer type. | Excellent chemical and weather resistance. |

| Applications | Flexible seals, automotive parts, medical devices. | O-rings, tires, hoses, heavy-duty seals. |

| Durability | Good fatigue resistance; less durable under extreme conditions. | Superior durability in harsh environments. |

Introduction to Thermoplastic Elastomers and Thermoset Rubbers

Thermoplastic elastomers (TPEs) are polymers that combine the elasticity of rubber with the recyclability and processing ease of plastics, softening upon heating and hardening on cooling without chemical change. Thermoset rubbers, in contrast, undergo a curing process that creates cross-linked molecular structures, resulting in a material that retains its shape and strength under heat but cannot be remelted or reshaped. These fundamental differences impact their applications, with TPEs favored for flexible, recyclable products and thermoset rubbers used in durable, heat-resistant components.

Chemical Structure Differences

Thermoplastic elastomers feature linear or branched polymer chains that allow them to be melted and reshaped multiple times due to physical cross-linking, whereas thermoset rubber has a heavily cross-linked, three-dimensional network formed by covalent bonds that prevent reshaping or melting once cured. The chemical structure of thermoplastic elastomers provides flexibility and recyclability, while thermoset rubber's chemically stable network ensures superior heat and chemical resistance. These fundamental differences in polymer architecture directly impact their mechanical properties and applications in industries requiring durability versus recyclability.

Processing Methods and Ease of Manufacturing

Thermoplastic elastomers (TPEs) offer superior ease of manufacturing due to their ability to be melted and reshaped repeatedly using injection molding, extrusion, and blow molding techniques. Thermoset rubber requires vulcanization, a chemical curing process that forms cross-links, making it more complex and time-consuming to process but resulting in a highly durable and heat-resistant product. Your choice depends on whether rapid production cycles and recyclability (TPEs) or enhanced mechanical strength and thermal stability (thermosets) are more critical for your application.

Physical and Mechanical Properties Comparison

Thermoplastic elastomers (TPEs) exhibit excellent flexibility, high tensile strength, and superior impact resistance, while maintaining the ability to be reshaped and reheated without degradation. Thermoset rubbers, such as vulcanized rubber, offer superior thermal stability, exceptional chemical resistance, and higher dimensional stability due to their crosslinked molecular structure, but they cannot be remelted or reshaped once cured. The mechanical properties of TPEs typically include lower hardness and stretchability compared to thermoset rubbers, which provide enhanced elasticity and durability in demanding applications like automotive seals and industrial gaskets.

Heat and Chemical Resistance

Thermoset rubber demonstrates superior heat and chemical resistance compared to thermoplastic elastomers due to its cross-linked molecular structure, which maintains integrity at elevated temperatures and exposure to harsh chemicals. Thermoplastic elastomers soften and deform under high heat, limiting their use in environments requiring prolonged thermal stability. Your choice should consider thermoset rubber for applications demanding robust performance against heat and aggressive chemical exposure.

Recyclability and Environmental Impact

Thermoplastic elastomers (TPEs) offer superior recyclability compared to thermoset rubber due to their ability to be melted and reshaped multiple times, significantly reducing environmental waste. Thermoset rubber, once cured, cannot be remelted or reshaped, leading to challenges in recycling and a higher environmental footprint. Choosing TPEs for your projects supports sustainability efforts by enabling easier material recovery and minimizing landfill contributions.

Cost Analysis: Material and Production

Thermoplastic elastomers (TPEs) generally offer lower production costs due to their ability to be melted and reshaped multiple times, reducing waste and enabling faster manufacturing cycles compared to thermoset rubbers, which require longer curing times and irreversible cross-linking processes. Material costs for TPEs can be higher per unit, but the efficiency in processing often leads to overall cost savings in large-scale production. Thermoset rubber materials typically involve more expensive raw materials and energy-intensive production, resulting in higher total costs despite their superior chemical and thermal resistance.

Typical Applications in Industry

Thermoplastic elastomers (TPEs) are widely used in automotive parts, medical devices, and consumer products due to their flexibility, ease of processing, and recyclability. Thermoset rubber finds application in tire manufacturing, industrial seals, and electrical insulation where superior heat resistance and durability are critical. Understanding the distinct performance characteristics of each material helps you select the most suitable option for your industrial needs.

Performance in Extreme Conditions

Thermoplastic elastomers maintain flexibility and resist cracking at low temperatures while withstanding repeated stress in extreme heat, making them ideal for applications requiring durability under variable conditions. Thermoset rubber offers superior chemical resistance and structural integrity at high temperatures but becomes brittle when exposed to freezing environments. Your choice between these materials depends on the specific temperature range and mechanical demands of your application.

Choosing the Right Material: Key Considerations

Choosing between thermoplastic elastomer (TPE) and thermoset rubber depends on factors such as flexibility, durability, and processing requirements. TPE offers ease of recycling and faster molding cycles, making it ideal for applications needing repeated flexibility and light assembly. Thermoset rubber provides superior heat resistance, chemical stability, and mechanical strength, suited for high-performance seals and automotive components exposed to harsh environments.

Thermoplastic elastomer vs Thermoset rubber Infographic

libmatt.com

libmatt.com