Rubber compound consists of a blend of raw rubber and various additives tailored to achieve desired mechanical properties, while a rubber masterbatch is a concentrated mixture of additives or pigments pre-dispersed in a carrier rubber to enhance processing efficiency and consistency. Using a rubber masterbatch allows you to streamline production and ensure uniform distribution of additives, improving the quality and performance of your final rubber products.

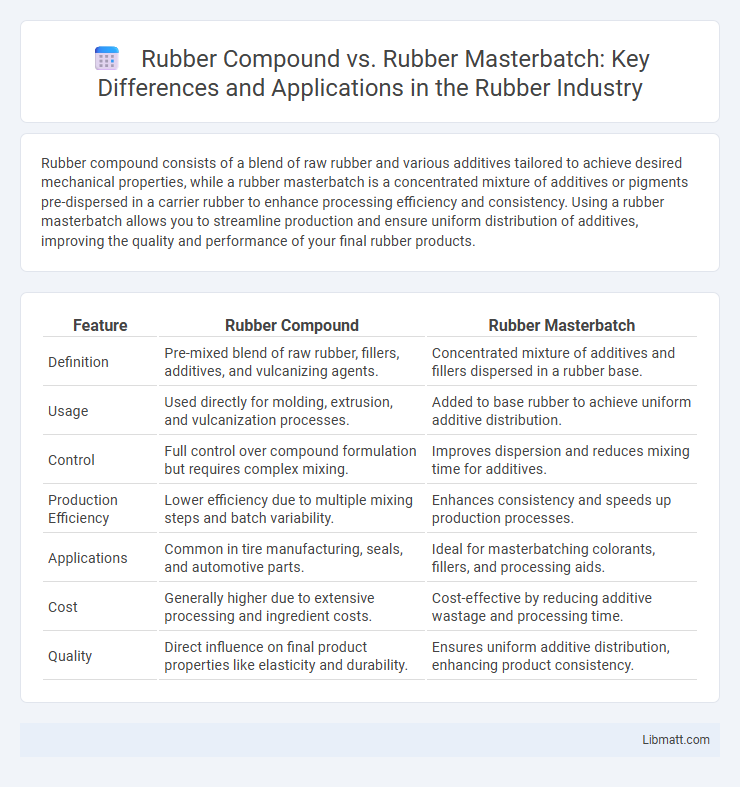

Table of Comparison

| Feature | Rubber Compound | Rubber Masterbatch |

|---|---|---|

| Definition | Pre-mixed blend of raw rubber, fillers, additives, and vulcanizing agents. | Concentrated mixture of additives and fillers dispersed in a rubber base. |

| Usage | Used directly for molding, extrusion, and vulcanization processes. | Added to base rubber to achieve uniform additive distribution. |

| Control | Full control over compound formulation but requires complex mixing. | Improves dispersion and reduces mixing time for additives. |

| Production Efficiency | Lower efficiency due to multiple mixing steps and batch variability. | Enhances consistency and speeds up production processes. |

| Applications | Common in tire manufacturing, seals, and automotive parts. | Ideal for masterbatching colorants, fillers, and processing aids. |

| Cost | Generally higher due to extensive processing and ingredient costs. | Cost-effective by reducing additive wastage and processing time. |

| Quality | Direct influence on final product properties like elasticity and durability. | Ensures uniform additive distribution, enhancing product consistency. |

Introduction to Rubber Compound and Rubber Masterbatch

Rubber compound consists of a blend of natural or synthetic rubber with additives like fillers, vulcanizing agents, plasticizers, and accelerators to achieve desired mechanical properties and processing performance. Rubber masterbatch is a concentrated mixture of specific additives or fillers pre-dispersed in a carrier rubber, designed to simplify and enhance the uniformity of the final rubber compound formulation. Both play critical roles in rubber manufacturing, with masterbatch improving consistency and ease of use within complex compound recipes.

Key Differences Between Rubber Compound and Rubber Masterbatch

Rubber compounds consist of natural or synthetic rubber mixed with additives like fillers, vulcanizing agents, and processing oils to achieve specific mechanical properties and performance criteria. Rubber masterbatches are concentrated mixtures containing high levels of fillers or additives, designed to be blended into base rubber compounds for enhanced dispersion and improved processing efficiency. Key differences include their composition concentration, purpose in manufacturing, and the role of masterbatches as additive carriers versus rubber compounds being final or intermediate materials ready for molding or extrusion.

Composition and Ingredients of Rubber Compound

Rubber compounds consist of a carefully balanced mixture of raw rubber, fillers, curing agents, processing oils, and additives that enhance specific properties like durability and elasticity. In contrast, rubber masterbatch contains a concentrated blend of pigments, fillers, and additives designed to be mixed into the base rubber compound to achieve uniform color or performance attributes. Understanding the detailed composition of each helps you tailor the final product's characteristics for superior quality and application-specific requirements.

Composition and Ingredients of Rubber Masterbatch

Rubber masterbatch consists mainly of pre-dispersed fillers, pigments, and additives uniformly mixed within a polymer carrier, allowing for enhanced control over rubber compound properties. Its composition includes high-quality elastomer matrices combined with processing aids and reinforcing agents, creating a ready-to-use blend that improves dispersion and overall compound consistency. You benefit from superior processability and reduced mixing time when incorporating rubber masterbatch into your rubber manufacturing workflow.

Manufacturing Processes: Rubber Compound vs Rubber Masterbatch

Rubber compound manufacturing involves directly mixing raw rubber with fillers, additives, and curing agents to achieve the desired properties, often requiring precise control of temperature and mixing time. Rubber masterbatch production focuses on creating a concentrated blend of additives and fillers that can be uniformly dispersed into the base rubber during final compounding, enhancing consistency and reducing mixing time. Your choice between these processes impacts product quality and manufacturing efficiency depending on the application requirements.

Performance Characteristics and Applications

Rubber compound offers enhanced mechanical properties such as improved tensile strength, flexibility, and abrasion resistance due to the uniform mixing of polymers, fillers, and additives, making it ideal for automotive tires and industrial seals. Rubber masterbatch contains concentrated additives or colorants that are mixed into virgin rubber to modify specific properties like color, UV resistance, or heat stability without altering the rubber's base structure, commonly used in consumer goods and footwear. Your choice between rubber compound and masterbatch depends on whether you need a fully formulated material for high-performance applications or a customizable additive to tailor specific rubber characteristics.

Cost Implications and Economic Considerations

Rubber compound production generally incurs higher raw material and processing costs due to the need for precise ingredient blending, affecting overall manufacturing expenditure. Rubber masterbatch offers cost advantages by providing pre-mixed, concentrated formulations that reduce material waste and improve processing efficiency, leading to lower production costs. Economic considerations favor masterbatch in large-scale applications where consistent quality and reduced downtime enhance profitability.

Environmental Impact and Sustainability Comparison

Rubber compounds often require higher volumes of additives and chemicals, leading to increased waste and environmental burden during production and disposal stages compared to rubber masterbatches, which allow for more precise additive dosing and reduced material usage. Rubber masterbatches improve sustainability by enhancing processing efficiency and lowering emissions due to their concentrated formulations that reduce energy consumption in manufacturing. Lifecycle assessments indicate that rubber masterbatches contribute to decreased carbon footprint and resource depletion, making them a more eco-friendly alternative to traditional rubber compounds.

Quality Control and Testing Methods

Rubber compound quality control relies on comprehensive testing methods such as tensile strength, hardness, and elongation to ensure consistency and performance meet industry standards. Rubber masterbatch quality control emphasizes uniform dispersion of additives and colorants, with testing methods including melt flow index and particle size distribution analysis to guarantee optimal processing and final product appearance. Your choice should consider these testing approaches to achieve the desired rubber product quality and functionality.

Choosing the Right Solution: Rubber Compound or Rubber Masterbatch

Choosing between a rubber compound and a rubber masterbatch depends on your production needs and desired material properties. Rubber compounds are pre-mixed formulations tailored for specific applications, offering consistent performance and ease of processing. Rubber masterbatches provide concentrated additives for enhancing rubber characteristics and flexibility in adjusting formulations during manufacturing.

Rubber Compound vs Rubber Masterbatch Infographic

libmatt.com

libmatt.com