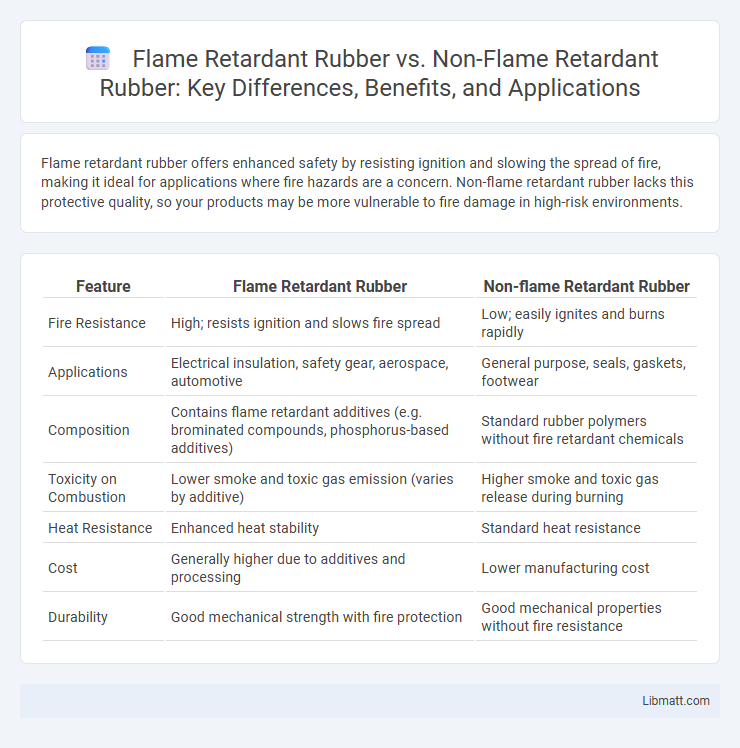

Flame retardant rubber offers enhanced safety by resisting ignition and slowing the spread of fire, making it ideal for applications where fire hazards are a concern. Non-flame retardant rubber lacks this protective quality, so your products may be more vulnerable to fire damage in high-risk environments.

Table of Comparison

| Feature | Flame Retardant Rubber | Non-flame Retardant Rubber |

|---|---|---|

| Fire Resistance | High; resists ignition and slows fire spread | Low; easily ignites and burns rapidly |

| Applications | Electrical insulation, safety gear, aerospace, automotive | General purpose, seals, gaskets, footwear |

| Composition | Contains flame retardant additives (e.g. brominated compounds, phosphorus-based additives) | Standard rubber polymers without fire retardant chemicals |

| Toxicity on Combustion | Lower smoke and toxic gas emission (varies by additive) | Higher smoke and toxic gas release during burning |

| Heat Resistance | Enhanced heat stability | Standard heat resistance |

| Cost | Generally higher due to additives and processing | Lower manufacturing cost |

| Durability | Good mechanical strength with fire protection | Good mechanical properties without fire resistance |

Introduction to Flame Retardant and Non-Flame Retardant Rubber

Flame retardant rubber contains specialized additives that inhibit or resist combustion, enhancing safety in applications requiring fire resistance. Non-flame retardant rubber lacks these additives, making it more susceptible to ignition and flame propagation under high-temperature conditions. The distinction is critical in industries like automotive, electronics, and construction, where compliance with fire safety standards is mandatory.

Key Properties of Flame Retardant Rubber

Flame retardant rubber exhibits enhanced thermal stability and reduced flammability compared to non-flame retardant rubber, making it essential for applications requiring fire resistance. Its key properties include self-extinguishing behavior, low smoke emission, and improved chemical resistance, contributing to increased safety in electrical insulation, automotive parts, and construction materials. These characteristics significantly extend the material's performance life in high-temperature or fire-prone environments.

Characteristics of Non-Flame Retardant Rubber

Non-flame retardant rubber typically exhibits high flexibility, excellent elasticity, and good resistance to abrasion and chemicals but lacks inherent fire resistance properties. It is prone to ignition and rapid combustion when exposed to open flames or high temperatures, producing harmful smoke and toxic gases. Common applications include automotive parts, seals, and hoses where fire resistance is not a critical requirement.

Chemical Composition and Flame Resistance Mechanisms

Flame retardant rubber incorporates chemical additives such as brominated compounds, phosphorus-based agents, or aluminum hydroxide, which alter its molecular structure to inhibit combustion and reduce heat release. These additives promote char formation and release flame-inhibiting gases that disrupt the combustion process, enhancing the material's overall fire resistance. In contrast, non-flame retardant rubber lacks these specialized additives, making it more susceptible to rapid ignition, sustained burning, and higher smoke production during exposure to fire.

Performance Comparison in High-Temperature Environments

Flame retardant rubber exhibits superior performance in high-temperature environments by resisting ignition and reducing flame propagation, enhancing safety in applications exposed to extreme heat. In contrast, non-flame retardant rubber tends to degrade quickly, losing elasticity and structural integrity when subjected to elevated temperatures, which can lead to material failure. The thermal stability and reduced smoke emission of flame retardant rubber make it the preferred choice for industries demanding high-performance materials under fire exposure conditions.

Fire Safety Standards and Regulatory Compliance

Flame retardant rubber meets stringent fire safety standards such as UL 94 and ASTM E84, ensuring your products comply with regulatory requirements for reduced flammability and smoke emission. Non-flame retardant rubber lacks these certifications, posing higher risks of ignition and toxic smoke in fire incidents. Selecting flame retardant rubber enhances compliance with industry regulations and improves overall fire safety in your applications.

Common Applications of Flame Retardant Rubber

Flame retardant rubber is widely used in electrical insulation, automotive components, and construction materials due to its enhanced resistance to fire and heat. Common applications include cable jacketing, gaskets, seals, and protective coatings in environments where fire safety is critical. This material's ability to slow ignition and reduce flame spread makes it essential for meeting safety standards in aerospace, public transportation, and industrial manufacturing sectors.

Typical Uses of Non-Flame Retardant Rubber

Non-flame retardant rubber is commonly used in applications where fire resistance is not a critical requirement, such as automotive seals, gaskets, and industrial hoses. This type of rubber offers excellent flexibility, durability, and resistance to abrasion and chemicals, making it suitable for everyday mechanical parts and consumer goods. Your choice of non-flame retardant rubber ensures cost-effective performance in environments without stringent fire safety regulations.

Environmental Impact and Toxicity Considerations

Flame retardant rubber contains chemical additives designed to inhibit or resist the spread of fire, but these additives can release toxic fumes and persistent pollutants during combustion, posing environmental and health risks. Non-flame retardant rubber typically avoids these hazardous chemicals, resulting in lower toxicity but increased flammability, which can lead to faster fire spread and higher immediate fire hazard. Balancing your choice requires assessing the trade-off between reducing fire risk and minimizing harmful environmental emissions during use and disposal.

Cost Analysis and Material Selection Guide

Flame retardant rubber typically incurs higher costs due to specialized additives that enhance fire resistance, making it essential for applications requiring stringent safety standards. Non-flame retardant rubber offers a more economical choice for general uses where fire risk is minimal, providing flexibility in budgeting and material selection. Evaluating the specific fire safety requirements and regulatory compliance is critical when selecting between flame retardant and non-flame retardant rubber to balance performance, cost-efficiency, and application needs.

Flame Retardant Rubber vs Non-flame Retardant Rubber Infographic

libmatt.com

libmatt.com