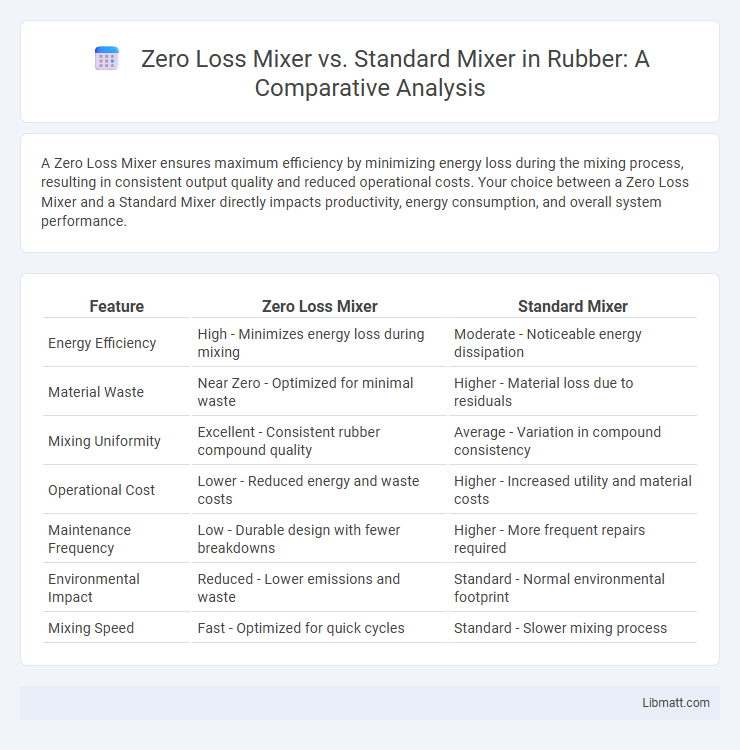

A Zero Loss Mixer ensures maximum efficiency by minimizing energy loss during the mixing process, resulting in consistent output quality and reduced operational costs. Your choice between a Zero Loss Mixer and a Standard Mixer directly impacts productivity, energy consumption, and overall system performance.

Table of Comparison

| Feature | Zero Loss Mixer | Standard Mixer |

|---|---|---|

| Energy Efficiency | High - Minimizes energy loss during mixing | Moderate - Noticeable energy dissipation |

| Material Waste | Near Zero - Optimized for minimal waste | Higher - Material loss due to residuals |

| Mixing Uniformity | Excellent - Consistent rubber compound quality | Average - Variation in compound consistency |

| Operational Cost | Lower - Reduced energy and waste costs | Higher - Increased utility and material costs |

| Maintenance Frequency | Low - Durable design with fewer breakdowns | Higher - More frequent repairs required |

| Environmental Impact | Reduced - Lower emissions and waste | Standard - Normal environmental footprint |

| Mixing Speed | Fast - Optimized for quick cycles | Standard - Slower mixing process |

Introduction to Mixer Technologies

Zero Loss Mixers utilize advanced signal processing to minimize insertion loss and preserve signal integrity, making them ideal for high-performance RF systems. Standard Mixers often experience higher conversion losses due to passive components, impacting overall system efficiency. Understanding these technologies helps you select the best mixer for optimizing your wireless communication or radar applications.

What is a Zero Loss Mixer?

A Zero Loss Mixer is a specialized fluid mixing device designed to minimize energy dissipation by ensuring the kinetic energy of fluid streams is preserved during the mixing process. Unlike standard mixers, which typically experience pressure drops leading to energy loss, Zero Loss Mixers maintain flow efficiency through optimized geometry and flow paths. This results in improved system performance, reduced operational costs, and enhanced mixing quality in various industrial applications.

How Standard Mixers Work

Standard mixers operate by mechanically combining materials through blades or paddles rotating within a mixing chamber, which often leads to material adhesion and residues on the surfaces. This process results in significant product loss due to material sticking to the mixer walls and blades, reducing overall efficiency. Understanding how standard mixers function helps identify the potential benefits of alternatives like Zero Loss Mixers to optimize your production yield.

Key Differences Between Zero Loss and Standard Mixers

Zero Loss Mixers minimize energy dissipation by using advanced design to maintain fluid velocity, whereas Standard Mixers often experience energy losses due to turbulence and inefficient flow patterns. The streamlined components in Zero Loss Mixers result in higher mixing efficiency and reduced operational costs compared to conventional designs. Your selection between these mixers can significantly impact process sustainability and energy consumption.

Efficiency and Performance Comparison

Zero Loss Mixers deliver superior efficiency by minimizing signal attenuation and power loss, resulting in higher conversion gain compared to Standard Mixers. Their advanced design reduces noise figure and enhances linearity, leading to improved overall performance in RF and microwave applications. Consequently, Zero Loss Mixers offer better sensitivity and dynamic range, making them ideal for demanding communication and radar systems.

Energy Savings and Cost Implications

Zero Loss Mixers significantly reduce energy consumption by minimizing pressure drops, resulting in energy savings of up to 30% compared to Standard Mixers. The improved efficiency lowers operational costs through decreased power requirements and reduced maintenance expenses over time. Initial investment in Zero Loss Mixers may be higher, but the long-term cost benefits due to energy savings and extended equipment lifespan offer substantial return on investment.

Application Scenarios for Each Mixer Type

Zero Loss Mixers excel in applications requiring minimal energy loss and high efficiency, such as pharmaceutical manufacturing and precision chemical processing. Standard Mixers are suitable for general industrial uses where cost efficiency and robust performance are priorities, including wastewater treatment and food production. Your choice depends on the need for energy savings versus operational versatility in your specific application.

Maintenance and Longevity Considerations

Zero Loss Mixers offer significantly reduced maintenance requirements compared to Standard Mixers due to their advanced sealing technologies that minimize wear and tear. Their design enhances longevity by preventing product contamination and reducing mechanical stress, extending the equipment's operational lifespan. Choosing a Zero Loss Mixer ensures your maintenance costs are lower and downtime is minimized, optimizing your production efficiency over time.

Environmental Impact Assessment

Zero Loss Mixers significantly reduce energy consumption by eliminating pressure drop-related losses compared to Standard Mixers, which directly lowers greenhouse gas emissions during industrial processes. Their design minimizes material wastage and decreases the need for frequent maintenance, resulting in less environmental pollution and resource depletion. Adopting Zero Loss Mixers contributes to improved sustainability metrics and compliance with stricter environmental regulations.

Choosing the Right Mixer for Your Needs

Zero Loss Mixers minimize signal attenuation by maintaining energy levels during mixing, making them ideal for high-precision audio or RF systems requiring minimal signal degradation. Standard Mixers, while more cost-effective, often introduce signal loss and noise, suitable for applications where budget constraints outweigh the need for signal integrity. Selecting the right mixer depends on balancing performance requirements with budget, considering factors like signal loss tolerance, application sensitivity, and overall system design.

Zero Loss Mixer vs Standard Mixer Infographic

libmatt.com

libmatt.com