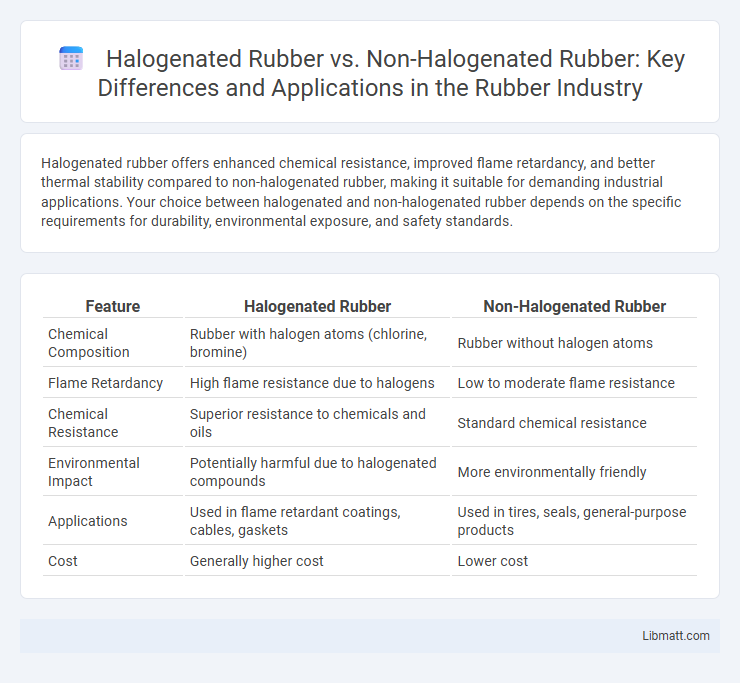

Halogenated rubber offers enhanced chemical resistance, improved flame retardancy, and better thermal stability compared to non-halogenated rubber, making it suitable for demanding industrial applications. Your choice between halogenated and non-halogenated rubber depends on the specific requirements for durability, environmental exposure, and safety standards.

Table of Comparison

| Feature | Halogenated Rubber | Non-Halogenated Rubber |

|---|---|---|

| Chemical Composition | Rubber with halogen atoms (chlorine, bromine) | Rubber without halogen atoms |

| Flame Retardancy | High flame resistance due to halogens | Low to moderate flame resistance |

| Chemical Resistance | Superior resistance to chemicals and oils | Standard chemical resistance |

| Environmental Impact | Potentially harmful due to halogenated compounds | More environmentally friendly |

| Applications | Used in flame retardant coatings, cables, gaskets | Used in tires, seals, general-purpose products |

| Cost | Generally higher cost | Lower cost |

Introduction to Halogenated and Non-Halogenated Rubber

Halogenated rubber contains halogen elements like chlorine or bromine chemically bonded to the polymer backbone, enhancing its chemical resistance, flame retardancy, and mechanical properties compared to non-halogenated rubber. Non-halogenated rubber, derived from natural or synthetic polymers without halogen atoms, offers flexibility and resilience but lacks the enhanced durability and resistance found in halogenated variants. Your choice between halogenated and non-halogenated rubber depends on the specific application requirements, such as exposure to harsh chemicals or fire safety standards.

Chemical Structure Differences

Halogenated rubber contains chemically bonded halogen atoms such as chlorine or bromine, which enhance its chemical resistance and flame retardancy compared to non-halogenated rubber. Non-halogenated rubber lacks these halogen atoms, resulting in a more flexible molecular structure but lower resistance to heat and chemicals. Understanding these chemical structure differences helps you select the appropriate rubber type for applications requiring specific durability and environmental resistance.

Key Types of Halogenated Rubber

Key types of halogenated rubber include chlorinated rubber, brominated rubber, and fluorinated rubber, each offering enhanced chemical resistance and improved flame retardancy compared to non-halogenated rubber. Chlorinated rubber is widely used in coatings and adhesives due to its excellent weather resistance and durability, while brominated rubber provides superior heat resistance and is commonly applied in automotive and electrical industries. Fluorinated rubber stands out for its exceptional chemical and thermal stability, making it ideal for harsh environments where non-halogenated rubber would degrade rapidly.

Common Types of Non-Halogenated Rubber

Common types of non-halogenated rubber include natural rubber (NR), styrene-butadiene rubber (SBR), and nitrile rubber (NBR), each known for unique properties such as high elasticity and resistance to abrasion or oils. You can rely on these non-halogenated rubbers for applications requiring flexibility and chemical resistance without the environmental concerns associated with halogenated variants. Their widespread use in automotive tires, seals, and industrial goods demonstrates versatility and cost-effectiveness in various industries.

Performance and Physical Properties Comparison

Halogenated rubber offers enhanced chemical resistance, improved flame retardancy, and better heat stability compared to non-halogenated rubber, making it ideal for demanding industrial applications. Non-halogenated rubber typically provides superior elasticity and lower cost but lacks the durability and resistance characteristics found in halogenated variants. Your selection depends on the balance between performance requirements such as mechanical strength, resistance to solvents, and environmental conditions.

Environmental Impact and Safety Considerations

Halogenated rubber, containing chlorine or bromine, releases harmful dioxins and toxic byproducts during production and disposal, posing significant environmental hazards compared to non-halogenated rubber, which is generally more eco-friendly and easier to recycle. Non-halogenated rubber reduces your exposure to hazardous substances and offers safer handling and disposal options due to its lower toxicity and less persistent environmental footprint. Choosing non-halogenated rubber supports sustainability and aligns with stricter environmental regulations aimed at minimizing pollution and health risks.

Cost Analysis and Market Availability

Halogenated rubber typically incurs higher production costs due to the additional chemical processing steps involved, impacting overall pricing compared to non-halogenated rubber. Non-halogenated rubber offers broader market availability and lower prices, making it a cost-effective choice for various industrial applications. Your selection should consider budget constraints and performance needs, balancing cost efficiency with functional requirements.

Typical Applications and Industries

Halogenated rubber is widely used in industries requiring enhanced chemical, heat, and weather resistance such as automotive, aerospace, and industrial coatings, often found in sealants, gaskets, and protective liners. Non-halogenated rubber is preferred in food processing, medical, and consumer products due to its superior environmental friendliness and lower toxicological impact, commonly utilized in gloves, tubing, and flexible membranes. Both types find niche applications in adhesives and elastomers, with halogenated variants favored for durability and non-halogenated types chosen for sustainability.

Advantages of Halogenated Rubber

Halogenated rubber offers enhanced chemical resistance and improved thermal stability compared to non-halogenated rubber, making it ideal for applications exposed to harsh environments. Its superior flame retardancy and resistance to oils and solvents extend the lifespan of your products in demanding industrial settings. This type of rubber also provides better adhesion to metals and other materials, increasing durability and performance reliability.

Benefits of Non-Halogenated Rubber

Non-halogenated rubber offers enhanced environmental compatibility due to its lower toxicity and reduced release of harmful halogenated compounds during production and disposal. It exhibits superior flexibility and elongation properties, improving durability and performance in dynamic applications such as automotive seals and gaskets. Additionally, non-halogenated rubber demonstrates better resistance to UV degradation and ozone, extending product lifespan in outdoor environments.

Halogenated Rubber vs Non-Halogenated Rubber Infographic

libmatt.com

libmatt.com