Co-crosslinking involves simultaneously forming crosslinks between polymer chains, resulting in a more uniform and interconnected network that enhances mechanical properties and stability. Sequential crosslinking, on the other hand, creates bonds in stages, allowing greater control over network architecture and enabling tailored material properties based on your specific application needs.

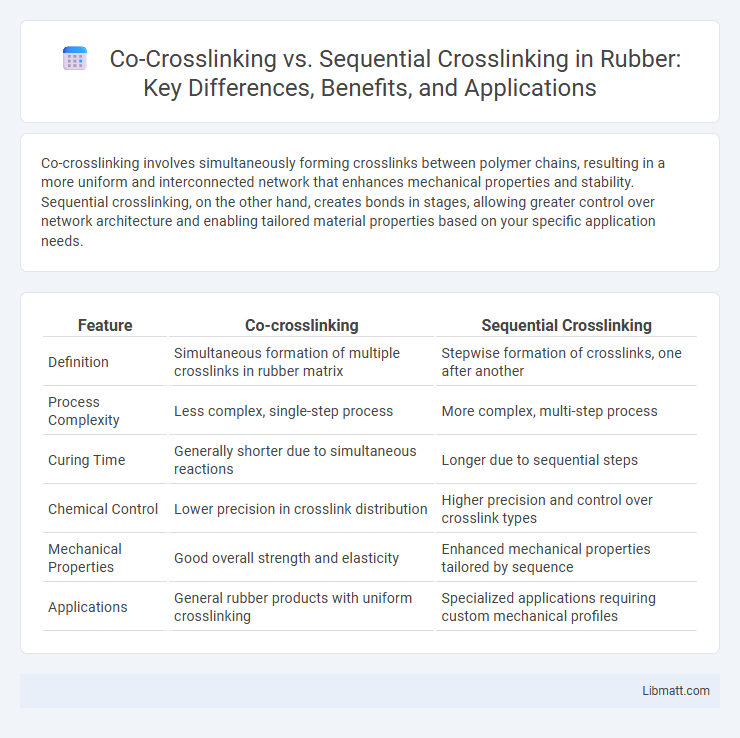

Table of Comparison

| Feature | Co-crosslinking | Sequential Crosslinking |

|---|---|---|

| Definition | Simultaneous formation of multiple crosslinks in rubber matrix | Stepwise formation of crosslinks, one after another |

| Process Complexity | Less complex, single-step process | More complex, multi-step process |

| Curing Time | Generally shorter due to simultaneous reactions | Longer due to sequential steps |

| Chemical Control | Lower precision in crosslink distribution | Higher precision and control over crosslink types |

| Mechanical Properties | Good overall strength and elasticity | Enhanced mechanical properties tailored by sequence |

| Applications | General rubber products with uniform crosslinking | Specialized applications requiring custom mechanical profiles |

Introduction to Crosslinking Techniques

Crosslinking techniques are essential in modifying polymer properties by forming covalent or ionic bonds between polymer chains. Co-crosslinking involves simultaneous crosslinking of multiple polymers or functionalities, resulting in a homogeneous network with enhanced mechanical strength and stability. Sequential crosslinking, by contrast, introduces crosslinks step-by-step, allowing for greater control over polymer architecture and tailored material properties that suit Your specific application needs.

Defining Co-crosslinking and Sequential Crosslinking

Co-crosslinking involves the simultaneous formation of crosslinks between polymer chains, resulting in a network structure created through concurrent chemical reactions. Sequential crosslinking occurs in stages, where crosslinks form in a stepwise manner, allowing for controlled modification of material properties at each phase. Understanding these distinct mechanisms helps you optimize polymer design for tailored mechanical strength and functionality.

Mechanisms of Co-crosslinking

Co-crosslinking involves simultaneous chemical reactions between multiple functionalities or polymer chains, promoting a homogeneous network structure through concurrent bond formation. This mechanism enhances polymer compatibility and interfacial adhesion by enabling covalent linkages across different polymer phases in a single step. Compared to sequential crosslinking, co-crosslinking reduces processing time and results in more uniform physical and chemical properties of the final material.

Mechanisms of Sequential Crosslinking

Sequential crosslinking involves a two-step process where an initial network forms through primary covalent bonds, followed by a secondary crosslinking phase that introduces additional bonds to enhance the polymer's mechanical and thermal properties. This method allows precise control over network architecture and crosslink density, resulting in tailored material performance. Your polymer's durability and functionality can be optimized by manipulating factors like crosslinking agents, reaction time, and environmental conditions during each step.

Comparative Analysis: Co-crosslinking vs Sequential Crosslinking

Co-crosslinking involves the simultaneous formation of crosslinks between polymer chains, resulting in a more uniform network with enhanced mechanical properties and improved thermal stability. Sequential crosslinking occurs in stages, allowing for tailored control of network density and spatial distribution, which can optimize flexibility and functionality in specific regions of the material. Comparative analyses show co-crosslinking tends to produce more homogeneous matrices, while sequential crosslinking offers greater customization for complex applications such as drug delivery systems and advanced composites.

Material Properties Affected by Crosslinking Methods

Co-crosslinking enhances uniformity in polymer networks, resulting in improved mechanical strength and thermal stability compared to sequential crosslinking, which often leads to heterogeneous structures and variable material properties. The simultaneous formation of crosslinks in co-crosslinking produces materials with higher elasticity and better resistance to chemical degradation. Your choice of crosslinking method directly influences properties such as tensile strength, elongation at break, and swelling behavior, critical for tailoring materials to specific applications.

Applications in Biomedical Engineering

Co-crosslinking enhances mechanical stability and uniformity in hydrogels, making it ideal for tissue engineering scaffolds that require consistent cell growth and nutrient transport. Sequential crosslinking allows for spatial and temporal control of gel properties, facilitating the development of advanced drug delivery systems and dynamic wound dressings with on-demand release profiles. Both techniques improve biocompatibility and tailoring of mechanical properties, crucial for biomedical implants and regenerative medicine applications.

Advantages and Limitations of Each Method

Co-crosslinking enables simultaneous bonding of multiple polymers, resulting in enhanced mechanical strength and uniform network structures, but it may lead to less control over individual polymer properties. Sequential crosslinking offers precise tuning of each polymer's characteristics by curing them step-by-step, providing tailored performance and improved compatibility; however, it requires longer processing times and more complex procedures. Your choice between these methods depends on balancing the need for structural uniformity against the desire for customizable polymer functionalities.

Recent Trends and Innovations

Recent trends in co-crosslinking emphasize simultaneous formation of multiple network structures, enhancing material strength and elasticity for advanced applications like flexible electronics and biocompatible hydrogels. Innovations in sequential crosslinking allow precise control over network architecture by introducing crosslinks in a stepwise manner, improving tunable mechanical properties and stimuli responsiveness critical for drug delivery and tissue engineering. Your choice between co-crosslinking and sequential crosslinking can optimize performance based on specific application demands such as durability or adaptive functionality.

Future Perspectives and Research Directions

Future perspectives in co-crosslinking emphasize the development of multifunctional hydrogels that integrate diverse polymer networks for enhanced mechanical strength and responsiveness, crucial for biomedical and tissue engineering applications. Research directions focus on optimizing reaction kinetics and compatibility of crosslinkers to achieve tunable properties and stimuli sensitivity, advancing smart material design. Sequential crosslinking offers precise spatial and temporal control, prompting investigations into multi-step curing processes and in situ modulation to create customizable, hierarchically structured materials.

Co-crosslinking vs Sequential crosslinking Infographic

libmatt.com

libmatt.com