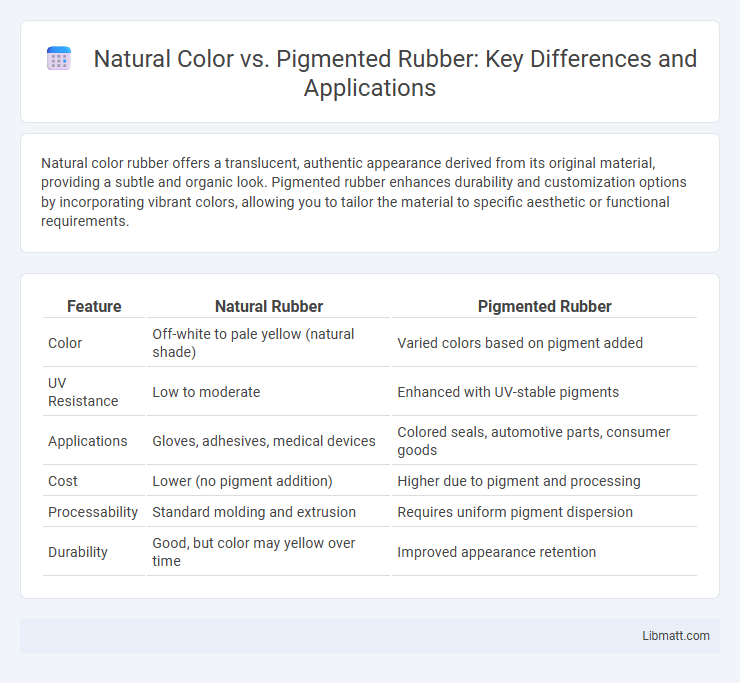

Natural color rubber offers a translucent, authentic appearance derived from its original material, providing a subtle and organic look. Pigmented rubber enhances durability and customization options by incorporating vibrant colors, allowing you to tailor the material to specific aesthetic or functional requirements.

Table of Comparison

| Feature | Natural Rubber | Pigmented Rubber |

|---|---|---|

| Color | Off-white to pale yellow (natural shade) | Varied colors based on pigment added |

| UV Resistance | Low to moderate | Enhanced with UV-stable pigments |

| Applications | Gloves, adhesives, medical devices | Colored seals, automotive parts, consumer goods |

| Cost | Lower (no pigment addition) | Higher due to pigment and processing |

| Processability | Standard molding and extrusion | Requires uniform pigment dispersion |

| Durability | Good, but color may yellow over time | Improved appearance retention |

Introduction to Natural Color and Pigmented Rubber

Natural color rubber retains the inherent off-white to light brown hue derived from latex extracted from Hevea brasiliensis trees, maintaining its organic composition without added dyes. Pigmented rubber incorporates synthetic colorants or pigments during manufacturing, enabling a wide spectrum of vibrant and customized colors while potentially altering physical properties. These differences influence applications in industries like automotive, healthcare, and consumer goods where both aesthetics and performance criteria are critical.

Composition of Natural Rubber

Natural rubber is primarily composed of polyisoprene, a polymer that gives it excellent elasticity and resilience, with minimal additives or pigments involved. Pigmented rubber, in contrast, includes natural rubber combined with various colorants and additives to achieve specific hues and enhanced properties like UV resistance. The base composition of natural rubber remains unchanged, but pigmentation alters physical characteristics and application versatility.

Pigmented Rubber: Additives and Coloring Agents

Pigmented rubber contains specialized additives and coloring agents such as carbon black, titanium dioxide, and organic pigments that enhance its visual appeal, UV resistance, and durability compared to natural color rubber. These additives improve performance characteristics by providing better color stability and protection against environmental factors. Your choice of pigmented rubber allows for customized colors tailored to specific application needs while maintaining the material's mechanical properties.

Production Process Differences

Natural rubber is harvested from latex sap collected directly from rubber trees, undergoing minimal processing to retain its original color and properties. Pigmented rubber involves the addition of specific dyes or pigments during the compounding process, which can alter its mechanical characteristics and require additional mixing and curing steps. Your choice between natural and pigmented rubber affects not only the visual outcome but also the complexity and cost of production.

Environmental Impact: Natural vs Pigmented Rubber

Natural rubber, harvested directly from Hevea brasiliensis trees, offers an environmentally friendly alternative due to its biodegradability and lower chemical processing requirements. Pigmented rubber often involves synthetic dyes and additives that can increase toxicity and reduce recyclability, impacting ecosystems negatively. Your choice of rubber type influences sustainability efforts by balancing performance needs with environmental impact.

Durability and Performance Comparison

Natural color rubber offers superior durability due to its minimal processing, retaining inherent strength and elasticity that withstands heavy wear and tear. Pigmented rubber, while versatile in appearance, may experience reduced performance as added pigments can slightly compromise its tensile strength and resistance to environmental factors. When choosing for applications requiring robust durability and consistent performance, your selection of natural color rubber often provides enhanced longevity compared to pigmented alternatives.

Applications in Industry and Consumer Goods

Natural rubber's translucent, off-white color offers advantages in industries requiring visual purity, such as medical devices and food packaging, where contamination detection is critical. Pigmented rubber, available in various colors, is preferred in consumer goods like toys, footwear, and automotive parts for aesthetic appeal and brand differentiation. Your choice between natural and pigmented rubber depends on the balance between functional transparency and visual customization needed for the specific application.

Cost Analysis: Natural Color vs Pigmented Rubber

Natural color rubber generally incurs lower production costs due to the absence of additional pigmentation processes, making it a cost-effective option for large-scale manufacturing. Pigmented rubber involves extra expenses for dyes and color mixing, which can increase material and labor costs, especially when custom colors or precise shades are required. Your choice should balance cost efficiency against the need for specific aesthetic or branding requirements, as pigmented rubber offers enhanced visual appeal but at a higher price point.

Safety and Health Considerations

Natural rubber, derived from latex, poses allergenic risks due to proteins that can trigger allergic reactions in sensitive individuals, impacting workplace safety. Pigmented rubber often contains added chemicals and dyes, which may release volatile organic compounds (VOCs) or other irritants during processing, necessitating proper ventilation and handling precautions. Ensuring Your environment minimizes exposure to potential allergens and chemical irritants enhances overall health and safety compliance.

Market Trends and Future Outlook

The natural color rubber market is gaining traction due to increasing demand for eco-friendly and sustainable materials in automotive and consumer goods industries. Pigmented rubber continues to dominate sectors requiring customized aesthetics and enhanced durability, driven by innovation in color stability and UV resistance technologies. Forecasts indicate a balanced growth trajectory, with natural color rubber expanding as regulatory pressures and environmental awareness push manufacturers toward greener alternatives.

Natural color vs Pigmented rubber Infographic

libmatt.com

libmatt.com